Kubudirira kwesimbi newelding nelaserinotsamira pahunhu hwayo hwepanyama. Semuenzaniso, kupenya kwakanyanya kunogona kutsausa simba relaser, nepo kupenya kwakanyanya kwekupisa kuchibvisa kupisa nekukurumidza kubva munzvimbo yeweld. Hunhu uhwu, pamwe chete nepokunyunguduka, zvinosarudza kuti chinhu chinotora simba zvakadii kuti chigadzire weld yakasimba uye chaiyo.

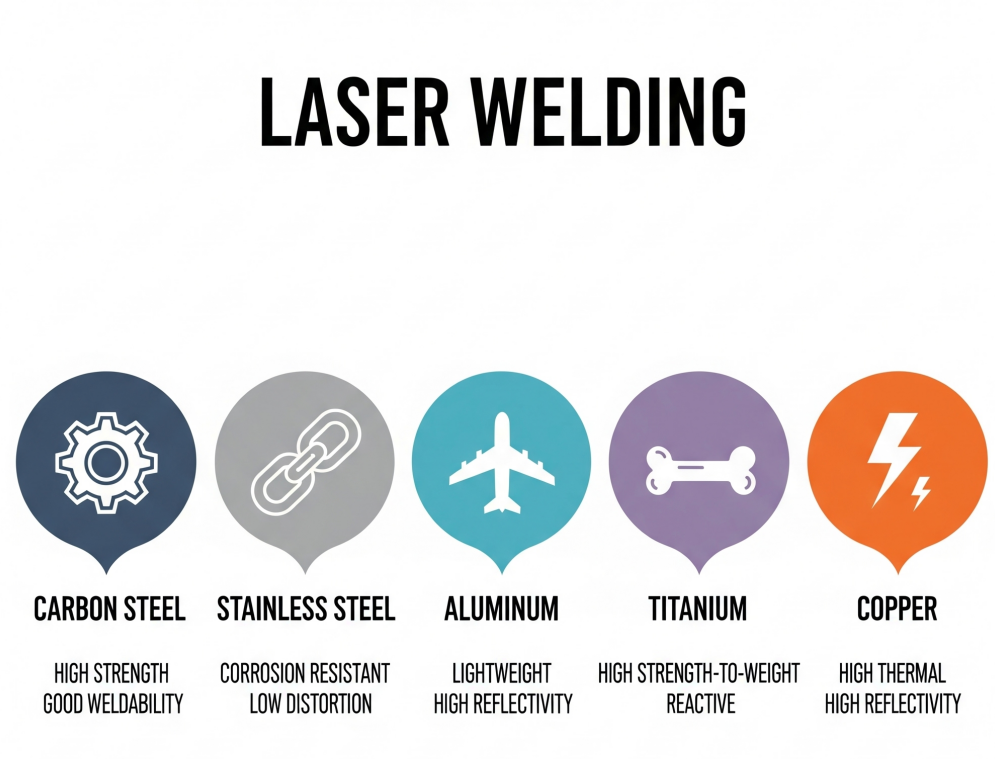

Heino kupatsanurwa kwesimbi dzakajairika uye kuti hunhu hwadzo hunoshanda sei.

Kushongedza neLaser Simbi yeCarbon

Simbi yekabhoni isimbi-kabhoni ine huwandu hwekabhoni hunosvika 2.1%. Hunhu hwekabhoni ndiyo inonyanya kusiyanisa hunhu hwayo.

Simbi isina kabhoni yakawanda(kabhoni iri pasi pe0.25%) inopfava, yakasimba, uye inogadziriswa nyore nyore uye inonamirwa. Inowanzoshandiswa kumapaneru emuviri, waya, uye mapaipi.

Simbi yekabhoni iri pakati nepakati(0.25% kusvika 0.60% kabhoni) yakasimba uye yakaoma kupfuura simbi isina kabhoni yakawanda. Izvi zvinoita kuti ikwanise kushandiswa muzvinhu zvinoda simba rakawanda uye zvinodzivirira kupera, zvakaita semagiya, shafts, uye mavhiri echitima.

Simbi ine kabhoni yakawanda(inopfuura 0.60% kabhoni) ndiyo yakasimba uye yakaoma pane dzose nhatu, asi zvakare ndiyo isinganyanyi kupfava uye inopwanyika zvakanyanya. Kuoma kwayo kunoita kuti ive yakakodzera kucheka maturusi, masipiringi, uye waya dzakasimba, asi inoda kubatwa nokungwarira panguva yekunamira kuti isatsemuke.

Simbi yekabhoni ibasa rakaoma mukugadzira, uye zvinotora nguva yakawanda kuti ushandise laser welding.

Zvakanakira: Unowana ma weld akasimba, akadzika nemazvo uye kukanganiswa kushoma. Kumhanya kwacho kunobatsira zvikuru, zvichiwedzera kugona kwekugadzira zvinhu pafekitori.

Zvaunofanira Kufunga Nezve: Kutonhora nekukurumidza kwemaitiro elaser kunogona kuita kuti weld itsvedze uye ive nyore kutsemuka. Dzimwe nguva, kupisa chikamu chacho kunodiwa kuti kunonotse kutonhora uye kudzivirira matambudziko.

Kushongedza neLaser Simbi Isina Kusimba

Izvi zvinofanana nezviri kuitika kudenga. Kubatanidza nelaser inzira yakakwana yesimbi isingatsvedzeri, kunyanya kumaindasitiri anoda kuchena.

Zvakanakira: Kupisa kwakaderera, kwakanangana nekupisa kwakanaka kwazvo. Kunochengetedza hunhu hwesimbi isingatsvi ngura nekudzivirira chimwe chinhu chinonzi "carbide precipitation." Izvi zvinoguma nekunatswa kwakachena uye kwakanyatsogadzirwa, ndosaka ichifarirwa zvikuru muindasitiri yezvekurapa neyezvekudya.

Zvaunofanira Kufunga Nezve: Simbi dzisingasvibi dzinowanzo shandiswa, senge 300 series (semuenzaniso, 304, 316), dzakanyatso sungirirwa zvakanaka. Zvisinei, mamwe magiredhi, senge 400 series, anogona kupwanyika munzvimbo ine kupisa.

Aruminiyamu Yekushongedza NeLaser

Kuwedera aruminiyamu kwagara kuri kwakaoma, asi kuwedera nelaser kuri kuchinja mutambo.

Zvakanakira: Aluminium inyanzvi yekupisa, zvichireva kuti kana tichisanganisa zvinhu zvechinyakare, kupisa kunopararira uye kunoita kuti chikamu chose chitenderere. Simba rayo rakatarisana nelaser uye kupisa kushoma zvinogadzirisa dambudziko iri, zvichideredza zvikuru kukanganiswa.

Zvaunofanira Kufunga Nezve: Aruminiyamu inopenya zvikuru. Nzvimbo inopenya inogona kusvetuka danda relaser pakarepo. Kubudirira kunoenderana nezvinhu zvishoma zvakakosha: kuchenesa nzvimbo isina tsvina, gasi rekudzivirira rakakodzera, uye kushandisa mhando chaiyo yelaser (fiber lasers inowanzo shandiswa) kuona kuti simba rayo rinonyudzwa.

Kushongedza Titanium neLaser

Kana uchida kusanganisa titanium, laser ndiyo imwe yezvishandiso zvako zvakanakisa pabasa racho.

Zvakanakira: Titanium isimbi inochinja-chinja, zvichireva kuti inosvibiswa nyore nyore neokisijeni iri mumhepo kana yanyunguduka, zvichiita kuti ive weld isina simba uye inopwanyika. Kumhanya uye kunyatsoita kwelaser zvinoderedza nguva iyo simbi inonyunguduka uye inoonekwa, zvichideredza njodzi yekusvibiswa uye kupwanyika.

Zvaunofanira Kufunga Nezve: Kungofanana neTIG welding titanium, unofanira kungwarira zvakanyanya. Kuchena kwakakwana uye kudzivirira zvakakwana negasi risina simba (senge argon) hazvigoneke kutaurirana.

Kukwesha kwemhangura nesimbi dzinoratidza chiedza uchishandisa laser

Apa ndipo panoshandiswa laser welding kusundira miganhu yezvinogona kuitika.

Zvakanakira: Muchina we laser welding unogona kubatanidza zvinhu zvinopenya zvakanyanya zvakaita semhangura, izvo zvakaoma zvikuru kubatanidza neimwe nzira. Izvi zvakakosha kune zvishandiso zvakaita semabhatiri emagetsi (EV), uko mhangura nearuminiyamu zvinofanira kubatanidzwa.

Zvaunofanira Kufunga Nezve: Izvi zvinhu zvehunyanzvi. Kupenya kwakanyanya uye kupisa kunogona kukanganisa magirazi elaser kana zvikasagadziriswa nemazvo. Kazhinji zvinoda michina yakasarudzika, pamwe chete nehunyanzvi hwepamusoro.

Chii chinonzi Lkutevedzera Laser Welding?

Kunyange zvazvo ichinzwika sechishandiso chinoshamisa, haisi yakakwana pabasa rega rega. Zvakakosha kunzwisisa zvinokanganisa.

1.Mutengo Mukuru Wekutanga: Muchina wekugadzira welding nelaser wehunyanzvi inyaya yekudyara mari yakawanda, inodhura zvakanyanya kupfuura michina yechinyakare yeMIG kana TIG.

2.Zvinodiwa Zvakasimba zveMajoini: Sezvambotaurwa, ma laser anoda kukwana zvakanaka. Kana zvikamu zvako zviine mipata kana kuti zvisina kuchekwa nemazvo, laser haizokwanisi kuzvibatanidza zvinobudirira.

3.Matambudziko ekufungisisa: Zvinhu zvinopenya zvakaita searuminiyamu nemhangura zvinogona kuoma kusanganisa pasina malaser nehunyanzvi hwemaindasitiri.

4.Zvinonetsa Nezvekuchengetedza: Mwaranzi welaser une simba guru une njodzi huru uye unogona kukonzera kukuvara kwakanyanya kwemaziso uye kutsva kweganda, kunyangwe kubva pakupenya. Zvivharo zvakakodzera zvekuchengetedza uye zvishandiso zvekudzivirira (PPE) zvinosungirwa zvachose.

Maitiro Akanakisisa Ekushandisa Laser Welds Isina Chikanganiso

Kuti uwane zvakawanda kubva mukuita kwako kwe laser welding, unofanirwa kutanga wanyatsonzwisisa zvinhu zvakakosha.

Kugadzirira ndizvo zvese

Kurongeka kweMajoini: Hatigoni kutaura zvakakwana: zvikamu zvako zvinofanira kubatana zvakanaka. Chinangwa chako ndechekuisa mukaha uri pasi pe10% yeukobvu hwechinhu chacho kuti uwane mhedzisiro yakanaka.

Kuchenesa Pamusoro: Bvisa zvese zvisiri zvesimbi. Izvi zvinoreva kubvisa mafuta ese, mafuta, ma oxide, nezvimwe zvinosvibisa. Nzvimbo yakachena yakakosha kudzivirira maburi nezvimwe zvikanganiso mu weld yako.

Dzora Maitiro Ako

Gasi rekudzivirira: Kufanana neTIG neMIG, laser welding inoshandisa gasi risina simba (kazhinji argon kana helium) kudzivirira dziva re weld rakanyungudutswa kubva kuokisijeni nenitrogen mumhepo, zvichiita kuti weld ive yakasimba uye yakachena.

Kugadzirisa Parameter: Unofanira kudhaira muzvirongwa zvako. Simba reLaser, kumhanya kwewelding, uye daro rekutarisa zvinofanirwa kuenzaniswa zvakakwana zvichienderana nezvinhu zvako uye ukobvu hwauri kushanda nahwo.

Kuchengetedzwa Kutanga, Nguva Dzose

Kubatanidza neLaser hakusi chinhu chaunogona kuita usina hanya nacho. Chiedza chakananga chine simba guru. Munhu wese ari pedyo nekushanda anofanira kupfeka magirazi ekuchengetedza eLaser akasarudzika zvichienderana nehurefu hwewavelength yeLaser yako.

Muchina weLaser Welding ndiyo Sarudzo Yakakodzera Kwauri Here?

Saka, unofanira kuisa mari mu laser welding here?

Ngatimbopfupikisai. Kuweda neLaser chishandiso chekugadzira chemhando yepamusoro chinopa kukurumidza, kunyatsorongeka, uye mhando isingaenzaniswi. Chinochinjaniswa ndechekuti mutengo wekutanga wakakwira uye zvinodiwa zvakanyanya kuti zvikamu zvakachena uye zvikwane zvakanaka.

Pfungwa yedu yekupedzisira: Kana basa rako richida vhoriyamu yakawanda, otomatiki, uye kunyatsorongeka—kunyanya pazvinhu zvakaoma kana zvakaoma—saka kushandisa laser welding haisi imwe sarudzo. Ndiyo mhinduro yepamusoro inogona kuchinja kugadzirwa kwako.

Nguva yekutumira: Nyamavhuvhu-15-2025