Bhuku reKushanda reRobhoti reKuwedhesa reLaser rinoshanda segwara rakakwana rinopa ruzivo rwekutanga pamusoro pekushandiswa uye mashandiro emidziyo inoshanda otomatiki inoshandisa matanda elaser pakuwedhesa. Bhuku iri rakagadzirirwa kubatsira vashandisi kunzwisisa matanho ekuisa, maitiro ekugadzirisa matambudziko uye maitiro ekushandisa anodiwa kuti marobhoti ekuwachisa elaser ashandise zvinobudirira uye zvakachengeteka. Nezvakanakira zvaro zvekushanda zvakanyanya, kunyatsojeka, uye mhando yepamusoro, marobhoti ekuwachisa elaser anogamuchirwa zvakanyanya mumaindasitiri akasiyana-siyana akadai sekugadzira mota, ndege, uye zvemagetsi.

Tsananguro yeChigadzirwa

Robhoti reLaser Welding mudziyo unoshanda otomatiki unoshandisa laser beam kuita mabasa ewelding. Chinangwa chikuru cheLaser Welding ndechekupisa nekunyungudutsa zvikamu zvakasungirirwa, zvichibatanidza zvinhu zvakanaka uye zvinobatanidza. Maitiro aya anobvumira welding chaiyo, zvichikonzera chigadzirwa chemhando yepamusoro. Marobhoti eLaser Welding anozivikanwa nekukwanisa kwawo kupa mhedzisiro yepamusoro yewelding, zvichiita kuti ave akakodzera maindasitiri anoda kukwana uye kuvimbika.

Matanho ekuisa

Kuiswa zvakanaka kwerobhoti re laser welding kwakakosha kuti rishande zvakanaka uye rigare kwenguva refu. Matanho anotevera anoratidza maitiro ekuisa:

1. Kuisa chimiro chemuchina: Kutanga, unganidza uye isa chimiro chemuchina cherobhoti re laser welding. Ita shuwa kuti zvikamu zvese zvakabatana zvakanaka uye zvakanyatsorongeka kuti zvigadzikane panguva yekushanda.

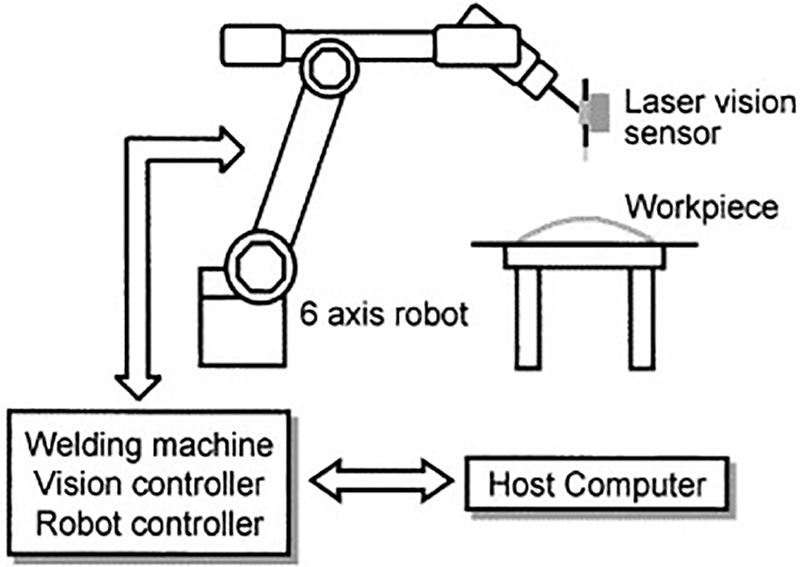

2. Kuisa sisitimu yekudzora: Isa sisitimu yekudzora yerobhoti re laser welding. Sisitimu iyi ine basa rekudzora mafambiro nemashandiro erobhoti uye inoita basa rakakosha mukuwana mhedzisiro chaiyo ye welding.

3. Kubatanidza magetsi netambo yechiratidzo: Batanidza magetsi nemazvo netambo yechiratidzo yerobhoti re laser welding kuti uve nechokwadi chekuti magetsi anowanikwa akavimbika uye asingadzoreki. Nyatsotevera dhayagiramu yewaya yakapihwa uye iva nechokwadi chekuti kubatana kwese kwakarurama.

Matanho ekugadzirisa matambudziko

Mushure mekunge robhoti re laser welding raiswa, rinofanira kugadziriswa zvakanaka kuti riite kuti rishande zvakanaka. Matanho anotevera anoratidza maitiro ekugadzirisa:

1. Kugadzirisa kutarisisa uye kusimba kwelaser beam: Gadzirisa kutarisisa uye kusimba kwelaser beam kuti uwane mhedzisiro yakanaka yekuwelda. Danho iri rinoda kugadziriswa kwakanyatsojeka uye kwakanyatsonaka kuti uve nechokwadi chekuti welding yakarurama.

2. Kugadzirisa kururama kwekufamba kwechimiro chemuchina: Gadzirisa kururama kwekufamba kwechimiro chemuchina kuti ubvise kusawirirana kana kusarongeka. Danho iri rakakosha pakuwana weld chaiyo uye yakaenzana.

Maitiro ekushanda

Kuti tive nechokwadi chekuti robhoti rinoshandisa laser welding rakachengeteka uye rinoita basa nemazvo, nzira dzakakodzera dzekushanda nadzo dzinofanira kutevedzerwa. Matanho anotevera anoratidza mashandiro akajairika erobhoti rinoshandisa laser welding:

1. Tanga kugadzirira: Usati watanga robhoti re laser welding, ongorora zvakakwana zvikamu zvese nezvinobatana kuti uve nechokwadi chekuti zviri kushanda zvakanaka. Tarisa kana paine njodzi kana zvikanganiso zvinogona kuitika.

2. Kugadziriswa kweLaser beam: Gadzirisa maparamita eLaser beam nokungwarira zvichienderana nezvinodiwa pakuwelda. Ita shuwa kuti focus, simba, nezvimwe zvinotevedzera zvinodiwa pakuwelda.

3. Kudzora maitiro ekuwelda: tanga maitiro ekuwelda zvichienderana nezvinodiwa. Tarisa uye dzora maparamita ekuwelda mukati mebasa rese kuti uwane mawelda akanyatsorongeka uye akafanana.

4. Kudzima: Mushure mekupedza maitiro ekubatanidza, ita maitiro akatevedzana ekudzima simba rerobhoti rekubatanidza nelaser zvakachengeteka. Izvi zvinosanganisira kuona kuti masystem ekudzora kutonhora nekudzima akakodzera.

Kufunga nezvekuchengetedza

Pakushandisa robhoti rinoshandisa laser welding, kuchengetedzeka kunofanirwa kukosheswa kudzivirira kukuvara kuvashandi nemidziyo. Danda re laser rinoshandiswa mukuita uku rinogona kuva nengozi kana rikasabatwa nemazvo. Saka, zvakakosha kutevedzera nhungamiro dzekuchengetedza dzinotevera:

1. Midziyo Yekudzivirira Munhu (PPE): Iva nechokwadi chekuti vashandi vese vari muchirongwa ichi vakapfeka PPE yakakodzera, kusanganisira magirazi ekuchengetedza ane dziviriro chaiyo yelaser nezvimwe zvinoshandiswa zvinodiwa.

2. Chidziviriro cheLaser beam: Ipa nzvimbo yakavharwa zvakanaka yerobhoti rinoshandisa laser welding nezvinhu zvakakodzera zvekudzivirira kudzivirira kusangana netsaona kwelaser beam.

3. Kumira Panjodzi: Isa bhatani rekumira panjodzi riri nyore kushandisa uye ita kuti rizivikanwe nevashandi vese. Izvi zvinogona kushandiswa senzira yekuchengetedza kana paine njodzi kana njodzi yaitika.

4. Kugadzirisa michina nguva dzose: Gadzira hurongwa hwekugadzirisa zuva nezuva kuti uve nechokwadi chekuti robhoti rinoshandisa laser welding riri kushanda zvakanaka. Gara uchitarisa uye uchichenesa zvikamu zvese zverobhoti, kusanganisira laser systems, mechanical structures, control systems, nezvimwewo.

Mukupedzisa

Bhuku reKushanda kweRobhoti reKuwelda reLaser chinhu chakakosha kune vashandisi vemidziyo inoshandisa magirasi elaser pakuita mabasa ekuwelda akanyatsojeka uye anoshanda. Nekuteerera matanho ekuisa, maitiro ekukomekedza uye maitiro ekushanda akatsanangurwa mubhuku rino, vashandisi vanogona kuwedzera kugona kwemarobhoti ekuwachira elaser mumaindasitiri akasiyana-siyana. Kuisa pamberi kuchengetedzeka uye kutevedzera gwara rinopihwa mubhuku rino kwakakosha kuhupenyu hwevashandi uye kugara kwenguva refu kwemidziyo. Nezvakanakira zvekushanda zvakanyanya, kunyatsojeka uye welding yemhando yepamusoro, marobhoti ekuwachira elaser anoramba achigadzira maitiro ekuwachira uye anobatsira mukufambira mberi kwekugadzira mota, ndege, zvemagetsi nedzimwe nzvimbo.

Nguva yekutumira: Mbudzi-22-2023