Muchina wako wekushongedza nelaser chinhu chine simba uye mari yakawanda. Asi nguva isingatarisirwi yekushanda, kushanda kusina kurongeka, uye kutadza kushanda zvakanaka zvinogona kushandura chinhu ichocho kuita mutoro mukuru. Mutengo wekutsiva laser source kana critical optics unogona kuva wakanyanya kushamisa.

Ko kana ukakwanisa kuwedzera hupenyu hwayo hune zvibereko, uchivimbisa kuti mhando yayo inogara iripo uye uchiwana mari yakawanda? Hazvisi zverombo rakanaka; ndezvehurongwa. Gwaro iri rinopa hurongwa hwakazara hwekuwedzera hupenyu hwemuchina wako we laser welding, zvichisanganisira zvese kubva pakugadzirisa kwezuva nezuva kusvika pakuronga kwenguva refu.

Zvinhu Zvinokosha Zvaunofanira Kuziva

Avhareji Yenguva Yehupenyu: Muchina unotarisirwa zvakanaka unowanzogara maawa 10,000 kusvika 30,000, asi izvi zvinogona kuwedzerwa zvakanyanya kana ukatarisirwa zvakanaka.

Nheyo Dzinokosha Dzekugara Urefu: Hupenyu hwemuchina hunoenderana nenzvimbo ina dzakakosha: Nzvimbo Yayo Yekushanda, Maitiro Ekushandisa, Kusimba Kwekuchengetedza, uye Unyanzvi Hwemushandisi.

Zvinonyanya Kutyisidzira Muchina Welding weLaser: Vavengi vakuru vemuchina wako kupisa kwakanyanya, guruva, hunyoro hwakawanda, simba risingachinji, uye kushanda nguva dzose kupfuura kugona kwawo kwakajairwa.

Ndeipi Avhareji Yehupenyu Hwemuchina Wekushongedza weLaser?

Muchina wekuwedera welaser unogara kwenguva yakareba uchishanda kwemaawa angangoita 10,000 kusvika 30,000. Zvisinei, iyi ifungidziro yakakura. Sezvatakakurukura, zvinhu zvakaita sekuchengetedza kwakanyatsonaka uye mamiriro ekunze akanaka zvinogona kukanganisa zvakanyanya kana muchina wako uchishanda zvakanaka kana kuti zvakanyanya kupfuura izvi—kana kutopfuura zvakanyanya.

Nekuda kwekufambira mberi mune tekinoroji, akawanda manyuko emazuva ano e fiber laser emhando yepamusoro ane hupenyu hunoshamisa hwemaawa angangoita 100,000. Asi hurefu hwemuchina wese hunoenderana nehutano hwese hwezvinhu zvawo zvakabatanidzwa, kwete chete sosi yacho.

Zvinhu Zvitanhatu Zvinokanganisa Kureba Kwenguva Yemuchina

Kunzwisisa zvinokonzera kushushikana kunoita kuti ukwanise kushandisa matanho ekudzivirira anonyatsoshanda.

1. Nzvimbo Yekushanda

Magadzirirwo emagetsi anonzwisisika uye magirazi anopenya anonyanya kukanganiswa nemamiriro azvo.

Kupisa & Hunyoro: Kupisa kwakanyanya kunodzvinyirira zvikamu, nepo hunyoro hwakawanda hunogona kukonzera kutonhora. Semuenzaniso, kudzikira kamwe kamwe kwekushisa kunogona kukonzera kutonhora pamagetsi emukati, zvichikonzera kukuvara zvachose.

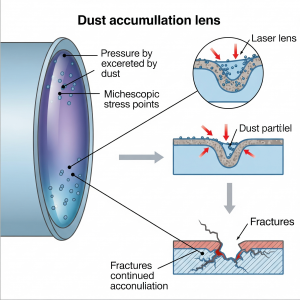

Kuchena: Guruva nemarara anofambiswa nemhepo zvinouraya chinyararire. Zvinogona kugara pamalenzi, zvichiita kuti mwenje welaser urasikirwe nesimba, kana kuvhara mafin ekutonhodza, zvichikonzera kupisa zvakanyanya uye kutadza kushanda kwezvikamu.

2. Kuwanda kwekushandiswa uye mutoro wekushanda

Kushandisa kwaunoita muchina uyu nesimba kunokanganisa zvakanyanya kufambiswa kwawo.

Kushandisa Zvakawandisa: Kumhanyisa muchina nguva dzose pasina zororo rakakwana kunotungamira mukushushikana kukuru kwekupisa uye kupera nekukurumidza kwelaser source uye cooling system.

Mitoro Yakawandisa: Kugara uchishanda nesimba rakawanda kana kuti pedyo nepamusana pesimba guru rinoisa simba guru pazvikamu zvinofamba. Ndosaka kunzwisisa nguva yebasa remuchina wako—nguva yakanyanya yekushanda nesimba rekubudisa—kwakakosha.

3. Kugadzikana kweChikamu cheElectronic

Kuvimbika kwekushanda kwe laser welding system kwakabatana nekugadzikana kwezvikamu zvayo zvemagetsi. Mabhodhi ekudzora, magetsi, uye madhiraivha edhiraivha zvinogona kukanganiswa nezvinhu zvakawanda zvinogona kukanganisa mashandiro, kunyatsojeka, uye hupenyu hwesystem.

Kushushikana Kwekupisa: Kuchinja kwekupisa uye kupisa kwenguva refu zvinokonzera kushushikana pamajoini e solder uye kukurumidzisa kuora kwezvikamu zvakaita se capacitors, zvichikanganisa kugadzikana kwesystem uye kutonga kwesimba.

Kuguma kweHupenyu hweChikamu: Zvikamu zvese zvine hupenyu husingagumi. Kuora kwezvinhu kusingadzivisiki kunotungamira mukukanganiswa kwekushanda, zvikanganiso zvinongoitika, uye kutadza kwesisitimu pakupedzisira, zvichida nzira yekutsiva nekukurumidza.

4. Simba reMagetsi Risingagadzike

Magetsi emagetsi anoshandiswa nelaser welder yako haakwanise kuzvidzivirira kubva kumagetsi asina kugadzikana. Kukwira kwemagetsi, kudonha, uye kumwe kushanduka kwemagetsi kunogona kukanganisa mabhodhi ekudzora uye sosi yemagetsi, zvichikonzera kutadza kushanda kana kukuvara kwakavanzika kunopfupisa hupenyu hwawo. Kupa tambo yemagetsi yakatsaurirwa uye yakagadziriswa nehunyanzvi hakusi kwekusarudza - chinhu chakakosha kuchengetedza midziyo yako uye kuona kuti inoshanda zvakanaka.

5. Gadzirisa Hurongwa Hwekugadzirisa Nekukurumidza

Nzira yekuti "gadzirisa kana yaparara" ndeimwe yenzira dzinokurumidza kupfupisa hupenyu hwemuchina wako wekunamira. Chirongwa chekugadzirisa chakarongeka uye chinoshanda nekukurumidza chakagadzirirwa kubata nekugadzirisa matambudziko madiki, senge sefa yakasviba kana chisimbiso chakasakara, zvisati zvaita kuti zvikanganise zvakanyanya. Kuona mberi uku hakungodziviriri chete kugadzirisa kunodhura, kwekukurumidzira uye nguva isina kurongwa yekushanda asi kunoderedzawo zvakanyanya mutengo wemuchina wese wekuva muridzi muhupenyu hwayo hwese.

6. Unyanzvi hweMushandi uye Kuranga

Kunyangwe muchina wakasimba zvikuru unogona kukanganisa vanhu. Mushandisi anoshandisa ma parameter asina kunaka nguva dzose, asingateereri zviziviso zvesystem, kana kusabata zvakanaka zvikamu zve optical zvinogona kukonzera kusakara nekukurumidza kana kutokuvara nekukurumidza. Kudzora mashandiro akakodzera uye kutevedzera Standard Operating Procedures (SOPs) zvakakosha. Kudzidziswa kwakazara kunoita kuti vashandisi vako vave mutsetse wekutanga wekudzivirira, zvichivapa simba rekushandisa muchina zvakanaka uye zvakachengeteka ukuwo uchivandudza hupenyu hwebasa rawo.

Nhungamiro Yekuwedzera Nguva Yehupenyu Hwako hweLaser Welder

Danho 1: Gadzira Nzvimbo Yakanaka Yekushanda

Kudzora Tembiricha & Hunyoro: Chengetedza nzvimbo yakagadzikana, inowanzo kuve pakati pe15℃ ne30℃ (59℉ne86℉), ine hunyoro huri pasi pe70%.

Iva nechokwadi chekuti mhepo yakachena: Shandisa nzira dzakasimba dzekufema uye funga nezvemasystem epamusoro ekusefa mhepo, kunyanya munzvimbo dzemaindasitiri, kudzivirira zvikamu zvemaziso nemagetsi kubva kuguruva.

Danho rechipiri: Shandisa Kuronga Kushandiswa Kwemazano

Dzivisa Kushanda Nesimba Rakawanda Nguva Dzose: Bvumira nguva dzakarongwa dzekutonhodza kana kuita mabasa akasimba kuti uderedze kushushikana kwekupisa. Funga nezvazvo sekushongedza injini yemotokari patsva—haina kugadzirwa kuti ishande zvakanaka nguva dzose.

Shandisa Mukati Mekukwanisa Kwakarongwa: Gara uchiremekedza magadzirirwo akagadzirwa nemuchina uye kutenderera kwebasa kuti udzivise kushushikana kwakanyanya pazvikamu zvemakanika nemagetsi.

Danho rechitatu: Zvipire kuRonga Rokugadzirisa Rakaoma

Kuchenesa Nekuzora Nguva Dzose: Gara uchichenesa zvinhu zvemaziso (malenzi, magirazi) uchishandisa mhinduro dzakatenderwa uye gadzira mafuta pazvikamu zvinofamba (magwara ekutungamira, mabheringi) kuti uderedze kukweshana.

Kutsiva Zvikamu Zvinoshanda: Usamirira kuti zvikamu zviputsike. Ronga purogiramu yekutsiva zvinodyiwa zvisina njodzi zvakaita semafirita nezvisimbiso zvichibva pane zvinokurudzirwa nemugadziri. Mutengo wekutsiva chikamu chinodyiwa nguva dzose, ingave hwindo rekuona kana firita remvura, mudiki kana tichienzanisa nemutengo wekukundikana kukuru kwakagadzirirwa kudzivirira.

Danho rechina: Isa mari mukudzidziswa kwevashandisi nerutsigiro rwenyanzvi

Kudzidziswa Kwakakwana Kwevashandi: Vashandi vane hunyanzvi vanonzwisisa kugona kwemuchina, marongero akakodzera eparameter, uye kugadzirisa matambudziko zvakakosha. Vanoderedza kushushikana pamuchina uye vanodzivirira kukuvara netsaona.

Shandisa Nyanzvi Yekugadzirisa: Kuti uwane kuongororwa kwakaoma, kutariswa, uye kugadziriswa, vimba nemainjiniya vane hunyanzvi. Kugara uchigadzirisa zvinhu kunogona kuona matambudziko asina kujeka asati ava matambudziko makuru.

Danho rechishanu: Gara Uchitarisa Hutano hweMuchina

Shandisa Kutarisa Kushanda: Shandisa maturusi aripo kuti utevedzere zviratidzo zvehutano zvakakosha zvakaita semagetsi chaiwo anobuda nelaser, kugadzikana kwekushisa kwechiller, uye makodhi ezvikanganiso. Michina yakawanda yemazuva ano inopa kuongororwa kweIoT-enabled yekugadzirisa mafambiro enguva.

Gadzira Kuongororwa Kwemhosva Nekukurumidza: Gadzira hurongwa hwakajeka hwekuona nekugadzirisa matambudziko nekukasika. Kukurumidza kutora matanho kunogona kumisa matambudziko kuti asapararire kuita kukuvara kwakakomba uye kwenguva yakareba yekusashanda.

Danho rechitanhatu: Ronga Kuvandudzwa Kwezvirongwa uye Kuvandudzwa

Gara Uchishandisa Tekinoroji: Kugadziridzwa kwesoftware kunogona kuvandudza kushanda zvakanaka uye mashandiro, dzimwe nguva kuwedzera hupenyu hwechikamu kuburikidza nekushandisa maalgorithms ekudzora akagadziridzwa.

Ongorora Kuvandudzwa Kwemichina: Pane nguva apo kuvandudza muchina wekare kunoderedza mari pane kugadzirisa nguva dzose. Funga izvi kana mari yekugadzirisa yava kunyanya kudhura kana tekinoroji itsva ichipa ROI yakakura.

Mhedziso: Chengetedza Mari Yako Yekudyara Kwemakore Anouya

Kuwedzera hupenyu hwemuchina wako wekuwelda nelaser hakusi kwechinhu chimwe chete chinonetsa; kunongova kushandisa nzira yakakwana uye inoshanda. Nekudzora nzvimbo yawo yekushanda, kuronga mashandisirwo awo nekuchenjera, kuzvipira kugadzirisa zvinhu zvakaoma, uye kuona kuti vanoushandisa vane hunyanzvi hwakanyanya, unogona kuwedzera mari yaunoisa, kuderedza nguva inodhura yekushanda, uye kuona kuti muchina wako unopa mhedzisiro yepamusoro kwemakore mazhinji ane zvibereko.

Mibvunzo Inowanzo bvunzwa (Mibvunzo Inowanzo bvunzwa)

Mubvunzo 1: Muchina we laser welder unofanira kugadziriswa kangani?

A: Izvi zvinoenderana nekushandiswa uye nzvimbo yekushanda. Mutemo mukuru ndewekutevedzera nguva dzebasa dzinokurudzirwa nemugadziri. Kuongororwa kwemaziso kwezuva nezuva nemushandi kwakakosha, nebasa rehunyanzvi rakanyatsoitwa kota yega yega, hafu yegore, kana gore rega rega.

Mubvunzo wechipiri: Ndeipi chikamu chinodhura zvikuru chekutsiva pamuchina we laser welding?

A: Chinhu chinogadzirwa nelaser ndicho chinodhura zvakanyanya, kazhinji chinosanganisira chikamu chikuru chemutengo wemuchina. Ndosaka kudzivirira muchina kubva pakupisa zvakanyanya uye kusvibiswa kwakakosha.

Mubvunzo wechitatu: Guruva rinogona kukanganisa muchina we laser here?

A: Zvechokwadi. Guruva rinogara pagirazi rinotarisisa rinogona kutora simba relaser, zvichiita kuti ripise uye ritsemuke, ritsve, kana kupwanyika. Izvi zvinokuvadza zvachose optic uye zvinokanganisa mashandiro emuchina zvakanyanya.

Mubvunzo wechina: Kumhanya nelaser nesimba rakaderera kunowedzera hupenyu hwayo here?

A: Ehe. Kugara uchishandisa muchina chero upi zvawo uri pasi pesimba rawo repamusoro kunoderedza kushushikana kwekupisa nemagetsi pazvikamu zvese, kunyanya sosi yelaser nemagetsi, izvo zvinogona kubatsira pakushanda kwenguva refu.

Unoda rubatsiro pakugadzira hurongwa hwekugadzirisa michina yako? Bata timu yedu yehunyanzvi nhasi kuti tikupe mazano.

Nguva yekutumira: Chikunguru-29-2025