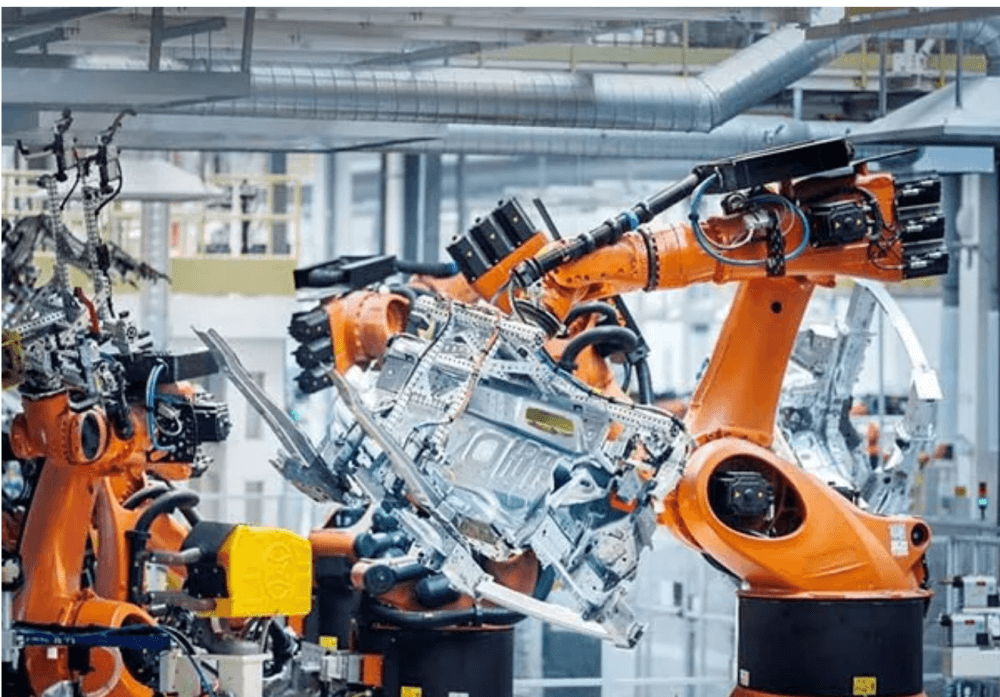

Marobhoti eLaser ekushongedzavakachinja nzvimbo yekuwelda nekuisa zvinhu zvepamusoro zvinowedzera kushanda zvakanaka uye kubereka. Marobhoti aya anopa mabasa akasiyana-siyana anorerutsa maitiro ekuwelda, anowedzera kunyatsojeka uye anovimbisa kuchengetedzeka kwakanyanya. Chinyorwa chino chine chinangwa chekuongorora kugona kwemarobhoti ekuwelda nelaser, tichisimbisa basa rawo mukuwedzera kushanda zvakanaka kwekuwelda uye otomatiki yakakwana. Tichaongororawo tsananguro dzakasiyana dzezvigadzirwa dzakadai sebasa rekusvetuka, basa rekuzvidzivirira, basa rekuona welding, basa rekudzivirira kurovera, basa rekuona kukanganisa, basa rekubatanidza waya inonamira, basa rekutangazve kwearc break.

1. Basa rekushambira:

Chimwe chezvinhu zvakakosha zverobhoti rekushandisa laserndiyo basa rayo rekutenderedza. Iyi nzira inobvumira robhoti kufamba nekufamba kwekufamba, ichifukidza nzvimbo yakakura kupfuura nzira dzekare dzekutenderedza. Iyi nzira yekutenderedza inoita kuti danda relaser rivhare nzvimbo yakakura, zvichideredza nguva yekutenderedza inodiwa kumapurojekiti makuru. Nekuwedzera nzvimbo yekufukidza, nzira yekutenderedza inobatsira kuwana kugona kwakanyanya uye kushanda zvakanaka mukushandiswa kwekubatanidza.

2. Basa rekuzvidzivirira:

Marobhoti ekugadzira nelaser ane zvinhu zvekuzvidzivirira kuti ave nechokwadi chekuti anogara kwenguva refu uye kudzivirira kukuvara kunogona kuitika. Chinhu ichi chinoshanda sechidziviriro kubva kumamiriro ezvinhu akaipa akadai sekunyanya kupisa, kutsauka kwemagetsi kana kushanduka kwesimba. Zvinhu zvekugadzira nerobhoti hazvingodziviriri chete zvikamu zvayo zvemukati, asiwo zvinodzivirira chero kukuvara kwekunze kubva kutsvina dzekugadzira kana marara. Nekuchengetedza kunaka kwayo, robhoti inogona kugara ichipa mhedzisiro yemhando yepamusoro yekugadzira nekuwedzera hupenyu hwayo.

3. Basa rekuona welding:

Kugona kuona weld chikamu chakakosha chemarobhoti ekugadzira welding nelaser, zvichiita kuti vakwanise kuona nekupindura kuchinja kuri kuitika munzvimbo yekunamira. Iyi ficha inoshandisa masensa epamusoro kuyera nemazvo zvinhu zvakaita sehukobvu hwesimbi, kurongeka kwemajoini uye tembiricha yekunze. Nekugadzirisa shanduko idzi munguva chaiyo, robhoti yekunamira inoita kuti kunamira kwakanyatsojeka munzira yaunoda, zvichikonzera kunaka kwehuku uye kuderedza kudiwa kwekugadzirisa nemaoko.

4. Basa rekudzivirira kuputika:

Kuchengetedzeka kwakakosha munzvimbo dzese dzemaindasitiri, uyemarobhoti ekugadzira welding nelaserVane zvinhu zvinodzivirira kuroverana kuti vasaroverane kana kukuvara. Izvi zvinoshandisa musanganiswa wemasensa, makamera, uye maalgorithms esoftware kuona zvipingamupinyi munzira yerobhoti. Kana yaonekwa, robhoti rinogadzirisa otomatiki nzira yaro kuti risaroverane. Izvi hazvingodziviriri robhoti kubva mukukuvadzwa chete, asiwo zvinovimbisa kuchengetedzeka kwevashandi nemidziyo iri pedyo, zvichibvisa njodzi yetsaona nekugadzirisa kunodhura.

5. Basa rekuona kukanganisa:

Kuti ive nechokwadi chekuti robhoti rinoshandisa welding nguva dzose uye risingadzoreki, robhoti rinoshandisa laser welding rine basa rekuona zvikanganiso. Basa iri rinogara richitarisa mashandiro erobhoti, kusanganisira zvinhu zvakaita setambo, magetsi, uye masisitimu ekutonhodza. Nekuona zvikanganiso zvinogona kuitika kana zvikanganiso pakutanga, marobhoti anogona kutora matanho ekudzivirira kana kuzivisa vanoshanda nezvedambudziko iri. Kuona nekugadziriswa kwezvikanganiso nenguva kunogona kubatsira kuwedzera kushanda zvakanaka, kuderedza nguva yekushanda uye kuwedzera kugona.

6. Kubatanidza waya inonamira uye kutangazve basa mushure mekupwanyika kwearc:

Chinhu chinoshamisa chemarobhoti ekugadzira nelaser welding kugona kubata matinji ewaya anonamira uye kutangazve maitiro ekugadzira newaya mushure mekupwanyika kwearc. Basa rekugadzira newaya rinonamira welding rinoita kuti robhoti rikwanise kunzwa nekugadzirisa kubatana newaya yekucheka, zvichiita kuti pave nemigumisiro yakanaka yekucheka kunyangwe pazvinhu zvakaoma. Pamusoro pezvo, basa rekugadzira nearc break restart rinobvumira robhoti kuti ritangezve kugadzira newaya mushure mekukanganiswa kwenguva pfupi pasina kupindira kwevanhu. Aya maficha anogonesa matinji emhando yepamusoro, anoderedza zvikanganiso uye anovandudza kushanda zvakanaka kwekugadzira newaya.

Mukupedzisa:

Marobhoti eLaser ekushongedzainopa zvinhu zvakawanda zvepamusoro zvinowedzera kushanda zvakanaka kwewelding uye zvinogonesa otomatiki yakazara mumabasa akasiyana-siyana. Chinhu chinotenderedza chinorerutsa kufukidzwa kwakarurama uye nekukurumidza, zvichiwedzera kugona. Kuzvidzivirira, kunzwa kwewelding, kudzivirira kurovera, kuona zvikanganiso uye mamwe mabasa anovimbisa kushanda kwakachengeteka, kwakarurama uye kunoramba kuripo. Pamusoro pezvo, welding sticky wire contact uye arc break restart mabasa anobatsira kuvandudza kunaka kwewelding uye kushanda zvakanaka kwese. Nekushandisa hunyanzvi uhwu hwepamusoro, marobhoti ewelding elaser akachinja zvakanyanya munda wewelding, zvichigonesa vagadziri kuwana mhedzisiro yepamusoro yewelding kuburikidza nekuwedzera otomatiki uye kubereka.

Nguva yekutumira: Nyamavhuvhu-03-2023