Munyika yanhasi iri kukurumidza, otomatiki yave chinhu chakakosha mumaindasitiri pasi rose. Kunyanya, kushandiswa kwemarobhoti ekugadzira welding nelaseryakachinja maitiro ekugadzira zvinhu muzvikamu zvakasiyana-siyana. Marobhoti aya ane mabhenefiti akawanda, kubva pakunyatsorongeka uye kururama kusvika pakuwedzera kushanda zvakanaka uye kuderedza mari yevashandi. Muchinyorwa chino, tinoongorora mashandisirwo akasiyana-siyana emarobhoti e laser welding uye kuti ari kuchinja sei maindasitiri akasiyana-siyana.

Indasitiri yemotokari inobatsirwa zvikuru nekubatanidzwa kwemarobhoti ekugadzira nelaser welding. Marobhoti aya anoshandiswa zvakanyanya mukugadzira muviri nekugadzira zvikamu. Nekunyatsorongeka kwawo uye kumhanya kwawo, marobhoti ekugadzira nelaser anovimbisa kuumbwa kwakakwana kwemajoini uye anobatsira mukugara kwenguva refu uye kusimba kwemotokari. Maitiro aya ega haangowedzere kugadzirwa chete, asiwo anoderedza mukana wekukanganisa, zvichikonzera mota dzemhando yepamusoro dzinosangana nekupfuura zvinotarisirwa nevatengi.

Kugadzira zvemagetsi ndeimwe nzvimbo iyo kushandiswa kwemarobhoti e-laser welding kwawedzera zvakanyanya. Marobhoti aya anoshandiswa pakushongedza zvikamu, zvichiita kuti pave nekubatana kwakanaka uye kwakavimbika mukati memidziyo yemagetsi. Pamusoro pezvo,marobhoti ekugadzira welding nelaseranoita basa rakakosha mukunamira mabhodhi edunhu, achivimbisa kubatana kwakanyatsojeka pakati pezvikamu zvega zvega. Nekugadzirisa maitiro ekugadzira, marobhoti aya anovandudza kunaka uye kugara kwenguva refu kwezvigadzirwa zvemagetsi uku achideredza njodzi yekukanganisa nekukundikana.

Indasitiri yendege, inozivikanwa netsika dzayo dzakasimba dzemhando yepamusoro, yatotangawo kushandisa marobhoti ekugadzira nelaser welding. Marobhoti aya anoshandiswa zvakanyanya mukushongedza zvikamu, zvichivimbisa kusimba uye kuvimbika kwezvikamu zvakakosha zvendege. Semuenzaniso, marobhoti ekugadzira nelaser welding anobatsira kushongedza mapapiro endege, zvichibatsira kuvandudza kuchengetedzeka uye kusimba kwezvivakwa izvi zvakakosha. Nekuita otomatiki maitiro ekushongedza, marobhoti aya haangowedzere kurongeka uye kururama chete, asiwo anoderedza njodzi yekukanganisa kwevanhu, izvo zvinogona kukanganisa kusimba kwechimiro chendege.

Indasitiri yekugadzira michina yekurapa inovimba zvakanyanya nemarobhoti ekucheka nelaser pakugadzira michina yekurapa. Marobhoti aya anovimbisa kusungirirwa kwakanyatsorongeka uye kwakarongeka kwezvikamu zvakaoma zvemidziyo yekurapa zvakaita semidziyo yekuvhiya uye maimplants. Nekuchengetedza mwero wepamusoro panguva yekugadzira,marobhoti ekugadzira welding nelaserzvinobatsira kuvandudza kuchengetedzeka uye kushanda zvakanaka kwemidziyo iyi yekurapa, zvichizobatsira murwere. Uyezve, hunhu hwayo hwe otomatiki hunowedzera kushanda zvakanaka kwekugadzira, zvichibvumira vagadziri kusangana nekudiwa kuri kuwedzera kwemidziyo iyi inoponesa hupenyu.

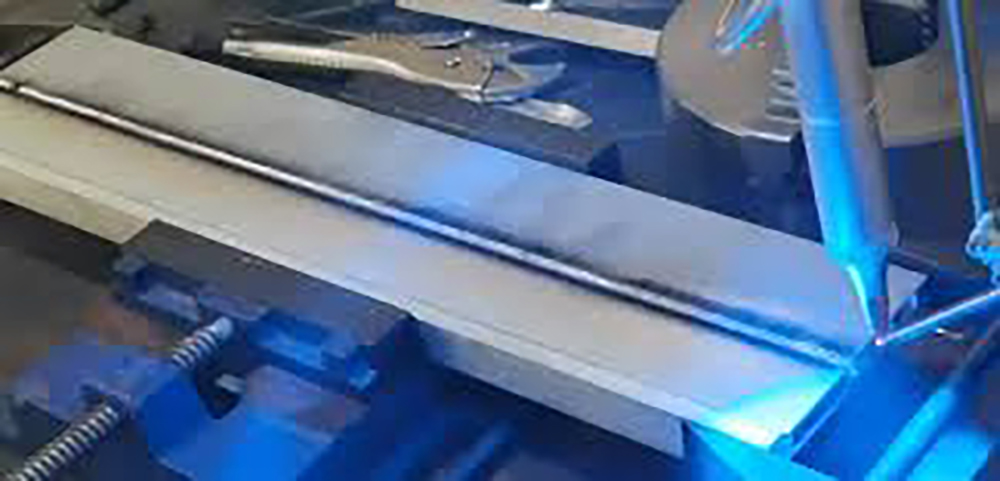

Muindasitiri yekuvaka, marobhoti ekugadzira nelaser awana nzvimbo yawo mukugadzira mapaipi nekugadzira pasi. Kugona kwemarobhoti aya kuita mawelds chaiwo munzvimbo dzakamanikana kwakabatsira zvikuru mukuvandudza mhando nekusimba kwemapombi anoshandiswa mumapurojekiti emapaipi nezvivakwa. Pamusoro pezvo, marobhoti ekugadzira nelaser anobatsira kusanganisa zvivakwa zvepasi, zvichiita kuti mapurojekiti ekuvaka agare kwenguva refu uye agare kwenguva refu. Marobhoti aya anowedzera kubereka uye anokurumidzisa maitiro ekuvaka, zvichikonzera kupedzwa kwemapurojekiti nenguva ukuwo achichengetedza mwero wepamusoro-soro.

Kuwedzera pakushandiswa kwemaindasitiri, marobhoti ekugadzira nelaser anobatsira zvikuru mudzidzo netsvagiridzo yesainzi.marobhotizvakaratidza kuva zvinokosha mukutsvaga nekuvandudza, marabhoritari emayunivhesiti nemasangano ekutsvagisa sainzi. Marobhoti ekugadzira nelaser anogonesa vaongorori kutsvaga matekiniki matsva ekugadzira nemidziyo, zvichisimudzira munda wetekinoroji yekugadzira nekubatanidza. Hunhu hwavo hwe otomatiki uye kunyatsoita basa ravo zvinobvumira masayendisiti kuita kuyedza nekururama kusingaenzaniswi, zvichitungamira mukuwana zvinhu zvitsva uye hunyanzvi muminda yakasiyana-siyana.

Muchidimbu, kushandiswa kwemarobhoti ekugadzira welding nelaseryakachinja maindasitiri akawanda, yakachinja maitiro ekugadzira uye yavandudza mhando yezvigadzirwa. Kubva pakugadzira mota kusvika kumagetsi, ndege, kugadzira zvishandiso zvekurapa, kuvaka, uye dzidzo netsvagiridzo yesainzi, kukanganisa kwemarobhoti e-laser welding hakurambiki. Nekuita mabasa e-welding otomatiki, marobhoti aya anopa kunyatsojeka, kugara kwenguva refu uye kushanda zvakanaka, zvichizowedzera kugadzirwa uye kuderedza mitengo. Sezvo maindasitiri achiramba achigamuchira otomatiki, remangwana remarobhoti e-laser welding rinotaridzika serinovimbisa sezvo richiramba richifambira mberi uye richichinja nyika yekugadzira.

Nguva yekutumira: Nyamavhuvhu-15-2023