Ma alloy e aluminium anoshandiswa zvakanyanya mumaindasitiri e semiconductor ne microelectronics nekuda kwehunhu hwawo hwakanaka hwemuviri nemakemikari uye hunhu hwakanaka hwemakanika. Sezvo zvigadzirwa zvemaindasitiri zvemazuva ano zvichikura zvine simba rakawanda, huremu, uye kushanda kwepamusoro, nzira dzekucheka ne laser dze alloy alloy dziri kufambira mberiwo kuti dzive dzakarurama, dzinoshanda zvakanaka, uye dzinochinjika. Kucheka ne laser kune zvakanakira kucheka kwakamanikana, nzvimbo diki inokanganiswa nekupisa, kushanda zvakanaka, uye kusava nekumanikidzwa kwemakanika mumipendero yekucheka. Yave nzira yakakosha yekugadzirisa nemazvo ma alloy e aluminium.

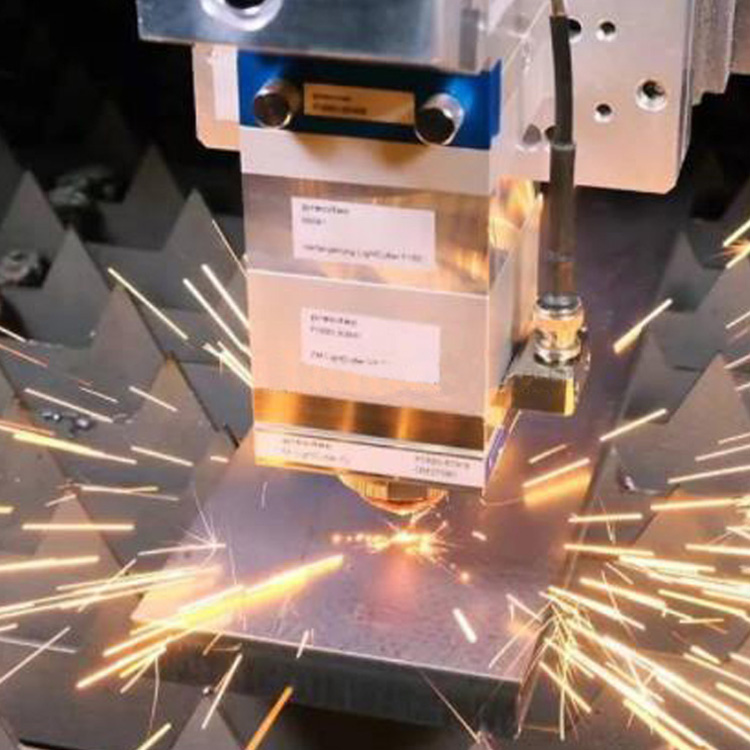

Kucheka kwelaser yealuminium alloy kuripo kunowanzo shandiswa musoro wekucheka pamwe negasi rekubatsira. Nzira yaro inoshanda ndeyekuti laser inotarisa mukati mealuminium alloy, gasification ine simba guru inonyungudutsa alloy yealuminium, uye gasi rekubatsira rine simba guru rinobvisa zvinhu zvakanyunguduka.

Nzira iyi yekucheka inonyanya kushandisa ma laser maviri ane ma wavelengths angangoita 10640nm uye 1064nm, ese ari maviri ari mu infrared wavelength range. Pakucheka kwakanyatsonaka kwe aluminium alloy sheets nehukuru hwekucheka hwakanyatsonaka pa micron level, nekuda kwenzvimbo yayo huru yechiedza nenzvimbo yakakura inokanganiswa nekupisa, zviri nyore kuti Slag uye micro-cracks iitike pamucheto wekucheka, izvo zvinozopedzisira zvakanganisa kururama uye mhedzisiro yekucheka.

Sisitimu yekucheka nearuminiyamu alloy laser uye nzira yekushandiswa kwayo inoita kuti kucheka kwechinhu chebasa chichekwe nenzira isingabatanidzi nekushandisa hupamhi hudiki hwepulse uye wavelength pfupi yelaser beam, kudzivirira kurasikirwa nekushushikana kwechinhu chebasa chichekwe nenzira dzemakanika, uye panguva yekucheka. Munguva yekugadzirisa, matambudziko akadai sekupwanyika kwemadiki uye kusungirirwa kweslag kunokonzerwa nekupisa; nekushandisa chinhu chakati kuti chigadzire chinhu chebasa chichekwe chakati twasu, ukuwo nzvimbo yekucheka ichiramba iri mumhepo, nzvimbo yekucheka yechinhu chebasa chichekwe inotsigirwa kubva kumashure kudzivirira kuti chisadonhe panguva yekucheka. Inogadzira kushushikana kuparadza mhedzisiro yekucheka; inoshandisa mvura inotonhorera inotenderera mumudziyo wetangi remvura kutonhodza chinhu chebasa chichekwe, inoderedza kupisa kwezvinhu zvakakomberedza, uye inowedzera kuvandudza kunaka kwekucheka; inocheka kuburikidza nemusanganiswa wenzira dzakawanda dzekucheka kuti iwedzere musono wekucheka. Upamhi hunovandudza kushanda zvakanaka kwekucheka.

Maitiro ari pamusoro apa ndiwo anonyanya kufarirwa, asi maitiro acho haagumiriswi nemaitiro ari pamusoro apa. Chero zvimwe zvishanduko, shanduko, zvitsiviso, musanganiswa, uye nyore nyore zvisingatsauki pane zvinorehwa nepfungwa nemisimboti zvinofanirwa kuitwa seizvi. Nzira dzinoshanda dzekutsiva dzese dziri muchikamu chekudzivirira nzira dzekucheka nearuminiyamu alloy laser.

Nguva yekutumira: Chivabvu-23-2024