Mumusika unotungamirirwa nehunyanzvi uye kushanda zvakanaka,welding nelaserinopa makambani efenicha yesimbi mukana wakajeka nekuwedzera purofiti, kugara kwenguva refu, uye kunaka kwemaonero.

Tekinoroji iyi inogadzira ma welds akanyatsojeka zvekuti anoda kupedzisa kushoma, inova ndiyo kiyi yekuvandudza uku. Izvi zvinoita kuti kugadzirwa kuitwe nekukurumidza, mari shoma yevashandi, uye rusununguko rukuru rwekugadzira, zvichibvumira kugadzirwa kwefenicha yakasimba uye yakanatswa zvakanaka ukuwo zvichiwedzera kushanda zvakanaka kwekugadzira.

Dhizaini Isina Muganho: Kukanganiswa kweLaser Welding paFenicha

Nzira dzekare dzekushongedza simbi dzaiwanzomanikidza vagadziri kuti vabvumirane. Masimbi anooneka, akakura aifanira kuvanzwa kana kugamuchirwa sechikamu chechitarisiko. Kushongedza nelaser kunoputsa zvipingamupinyi izvozvo.

Kuzadzisa Hope Dzisina Kujeka NemaWelds Asingaonekwe

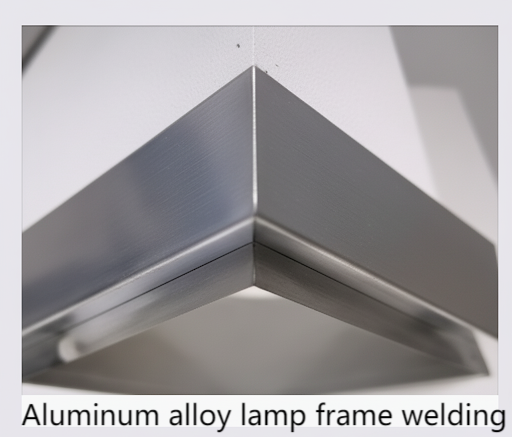

Kugadzira fenicha yemazuva ano kunobudirira kana paine zvinhu zvakachena uye runako rudiki. Kugadzira nelaser welding ndiyo nzira yakakwana yekuchinja uku. Inogadzira majoini akapfava, asina musono akakodzera fenicha yepamusoro-soro uko kusona kunooneka kusingagamuchirwi. Mugumisiro wacho chigadzirwa chinoita sechakagadzirwa nesimbi imwe chete.

Kugadzira Mapatani Akaoma uye Majiometri

Wakamboda kugadzira simbi dzakapfava uye dzakaomarara dzekushongedza here? Kunyatsoita kwemuti welaser kunoita kuti zvikwanisike. Iyi tekinoroji inogonesa kugadzirwa kwemapatani akaomarara uye maumbirwo ejometri ayo aisazogoneka nenzira dzechinyakare, idzo dzinowanzo kukonzera kukanganiswa kwekupisa uye kukanganisa zvinhu zvidiki.

Kugadzira Zvinhu Zvitsva Nemichina Yakasanganiswa

Kupinza kwelaser welding pasina kupisa kwakanyanya ndeimwe mukana mukuru. Izvi zvinobvumira simbi kusungirirwa pedyo zvakanyanya nezvimwe zvinhu zvakaita sehuni, girazi, kana upholstery pasina kukonzera kukuvara. Izvi zvinovhura nyika itsva yemagadzirirwo efenicha matsva, akasanganiswa nezvinhu.

Sarudzo Yakajeka: Nei Laser Welding Ichishanda Zvakanaka Kupfuura Matekiniki Echinyakare

Kana zvasvika pakugadzira fenicha yesimbi, sarudzo pakati pekushandisa laser welding nenzira dzechinyakare dzeMIG kana TIG iri kuramba ichijeka.

Kumhanya uye Kuburikidza

Nguva inodhura zvikuru pakugadzira zvinhu. Kucheka nelaser kunokurumidza kagumi kupfuura nzira dzechinyakare. Kumhanya uku kunoshamisa kunoderedza nguva yekugadzira chigadzirwa chimwe nechimwe, kunowedzera simba rekugadzira, uye kunoita kuti zvigadzirwa zvikwanise kutengeswa nekukurumidza.

Hunhu uye Kupedzisa

Kanganwa matanho echipiri anotora nguva yakawanda ekukuya, kukwesha, uye kupukuta. Kukwesha neLaser kunoita kuti pave nekukwesha kusina kupararira zvakanyanya uye nzvimbo diki ine kupisa (HAZ). Izvi zvinoreva kuti chigadzirwa chapera chinobva chabuda zvakanaka, zvichibvisa mari yakawanda uye inoda simba mushure mekugadziriswa.

Simba uye Kunyatsorongeka

Usarega chitarisiko chakachena chichikunyengedza; ma weld aya akasimba zvikuru. Ma weld akadzika, akatetepa akagadzirwa nelaser anowanzova akasimba kupfuura chinhu chikuru. Maitiro acho akanyatsojeka, izvo zvinoderedza kukanganiswa kwezvinhu uye marara.

Kuenzanisa Nzira Yekushongedza: Laser vs. MIG vs. TIG

| Chiyero | Kushongedza neLaser | Kushongedza kweMIG | Kushongedza kweTIG |

| Kumhanya | Yakakwirira Zvikuru | Yakakwirira | Zvishoma nezvishoma |

| Kunyatsojeka | Zvinoshamisa | Zviri pakati nepakati | Yakakwirira |

| Hunhu Hwakazara | Yakanaka kwazvo (isina musono) | Zvakanaka (Zvinoda Kukuya) | Zvakanaka (Zvinoda Kucheneswa) |

| Kugadziriswa Mushure meKugadzirwa | Zvishoma kusvika Hapana | Yakakura | Zviri pakati nepakati |

| Unyanzvi hweMushandil | Zviri Nyore Kudzidza | Zviri pakati nepakati | Yakakwirira |

| Mutengo wekutanga | Yakakwirira | Zvakaderera | Zvakaderera |

Kubva paFuremu kusvika kuFiligree: Mashandisirwo Ekugadzira Laser Welding Enyika Yese

Saka, tekinoroji iyi inoshanda sei kuzvigadzirwa zvako chaizvo? Heano mimwe mienzaniso inoshanda:

Zvikamu zveMaumbirwo:Unganidza mafuremu, makumbo, uye zvinhu zvinotsigira matafura nezvigaro zviri nyore uye zvine simba uye zvakanyatsonaka nguva dzese.

Kushongedza Simbi:Gadzira ma weld akanaka, ane ruzivo rwakadzama pazvishongedzo, zvakaita sezvigaro zvechigaro zvine mapatani kana matafura ehunyanzvi, izvo zvinochengetedza runako rwakazara.

Zvinhu Zvitete & Makabati:Batanidza simbi yakatetepa pamakabati, makabati, uye mapaneru pasina kukombama kana kutsva sezvinoitwa nedzimwe nzira.

Mashandisirwo aya anoratidza kuti kunyangwe basa iri richida kuvakwa kwakasimba kana kuti kushongedza kwakaoma, kushongedza nelaser inzira inochinjika. Inovhura mukana wekugadzira zvinhu zvitsva uye mwero wepamusoro wemhando, ichivimbisa kuti zvigadzirwa zvako hazvina kungogadzirwa kuti zvigare kwenguva refu chete asiwo zvakagadzirwa zvakakwana.

Vhura Simba reLaser Welding: Makiyi Matatu Ekutanga Pasina Chikanganiso

Kushandisa laser welding inzira yakanaka yekuvandudza kugona kwako kugadzira zvinhu. Kuti ushandise simba rayo rose kubva pazuva rekutanga, batanidza nheyo idzi dzekutanga mubasa rako.

Kunyatsojeka ndiyo hwaro hwekushanda zvakanaka

Kunyatsorongeka kwe laser welding kunotanga kare kare beam isati yatanga kushanda. Kunoenderana nekubatana kwakakwana pakati pezvikamu. Nekugadzirisa maitiro ako ekucheka nekugadzira kumusoro kuti ugadzire zvikamu zvine mipata mishoma, unogadzirira nzira ye weld dzakasimba, dzakachena, uye dzakagadzikana.

Kuchena Kunovhura Mikana

Nzvimbo yakachena yakakosha kuti pave ne weld yakakwana. Chero mafuta, tsvina, kana kunyange ganda re oxide rechisikigo riri paaruminiyamu rinogona kukonzera zvikanganiso uye kukanganisa kuvimbika kwejoinhi. Kutanga danho rekuchenesa nekugadzirira rinosungirwa kunoita kuti laser igadzire musono wakachena, une simba, uye wakakwana nguva dzese.

Tsika Yekuchengetedza Inoita Kuti Pave Nekubudirira

Malaser ane simba guru anoda nzira yekukurumidza kuchengetedza. Kuchengetedza timu yako ndicho chinhu chekutanga chaunonyanya kukoshesa. Izvi zvinoreva kugadzira nzvimbo yakachengeteka ine nzvimbo dzekushandira dzakatsaurirwa, dzakavharirwa, kugadzirisa hunhu hwemhepo nekuburitsa utsi zvinobudirira, uye kupa munhu wese munharaunda iyi miwani yemaziso yakasimbiswa kuti isaparare nelaser. Kushanda kwakachengeteka inzira inoshanda uye inogara kwenguva refu.

Kuramba Uri Mberi: Remangwana reKushongedza Kwemagetsi

Tekinoroji iyi ichiri kushanduka, ichisimudzira miganhu yezvinogona kuitwa mukugadzira fenicha yesimbi.

Kukwira kweRobotics neCobots

Kugadzira otomatiki kuri kuita kuti welding yelaser ishande zvakanyanya. Kubatanidza ma laser welders nemaoko erobhoti uye marobhoti anoshanda pamwe chete (cobots) kunobvumira kugadzirwa kwemaawa makumi maviri nemana pazuva, mazuva manomwe pasvondo, zvichiita kuti tekinoroji iyi ive nyore kuwanikwa nevagadziri vehukuru hwese.

Kugadzira Kwakangwara neAI uye Kudzidzira Kwemuchina

Ramangwana rine hungwaru. Sekureva kwemishumo yeindasitiri ichangoburwa, AI nekudzidza kwemuchina zviri kubatanidzwa muhurongwa hwekuwelda kuti zvionekwe kuti mhando yechinhu inoshanda sei, zviziviso zvekuchengetedza zvinofanotaurwa, uye kugadzirisa otomatiki maitiro, zvichiita kuti weld yega yega ive yakakwana.

Chikamu Chitsva Mukugadzira Fenicha

Muchidimbu, laser welding haisi chinhu chitsva chete. Imari yekudyara ine hunhu husina muganho, kukurumidza kugadzirwa, uye rusununguko rwekugadzira. Inokupa simba rekupa zvigadzirwa zvinoyevedza zvine misono isingaoneki, kuzvigadzira nekukurumidza kunopfuura vakwikwidzi, uye kupa vagadziri vako rusununguko rwekugadzira zvinhu zvitsva pasina muganho. Uyu mukana wako wekuwana chinzvimbo chepamusoro muindasitiri yefenicha.

Regai tikuratidzei mabhenefiti anooneka ezvigadzirwa zvenyu. Taurai nenyanzvi dzedu dzekugadzira kuti muwane mazano akakodzera uye torai danho rekutanga rekuenda kumberi kwefenicha.

Nguva yekutumira: Nyamavhuvhu-28-2025