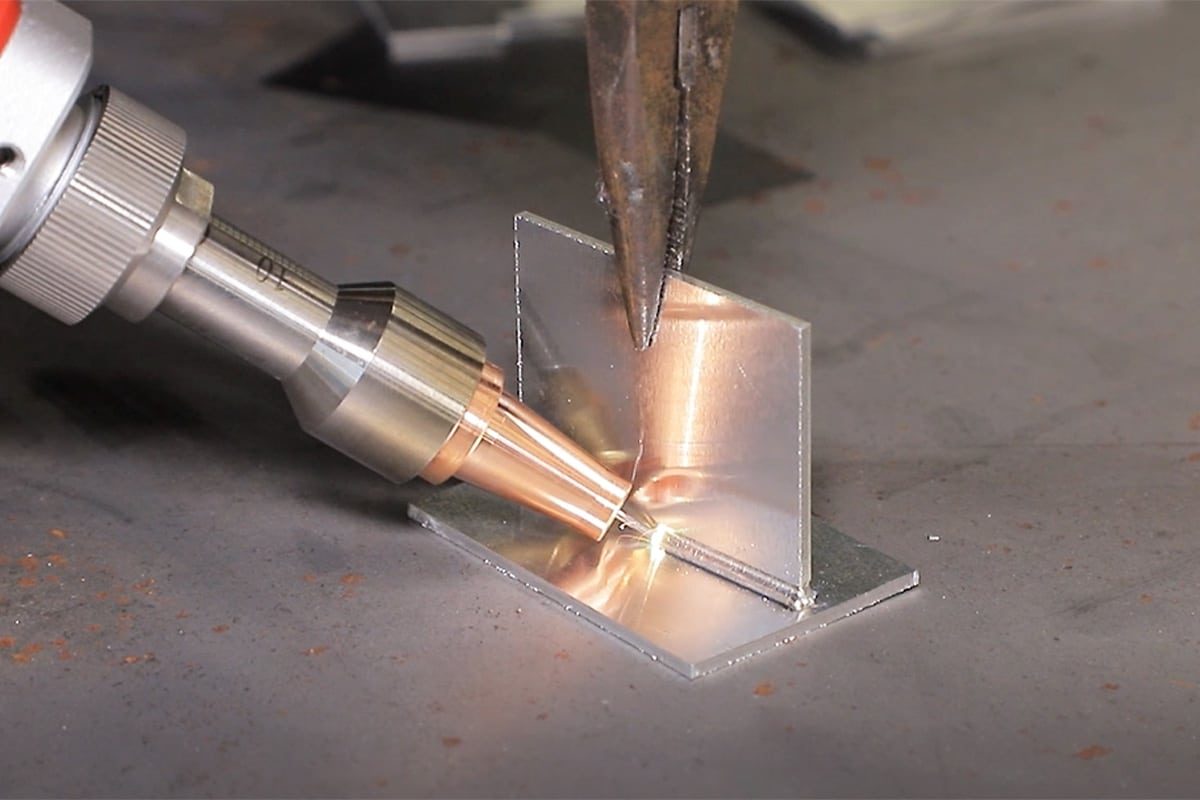

Kune mainjiniya, vagadziri, uye vatariri vemabasa, dambudziko iri rinogara riripo: nzira yekubatanidza zvikamu zvesimbi isingatsvedzereki pasina kupetana, kuchinja ruvara, uye kudzikira kwekudzivirira ngura uko kunotambudza nzira dzemazuva ano. Mhinduro ndeiyi:simbi isina ngura inosungirirwa nelaser, tekinoroji inoshandura zvinhu inopa kumhanya, kunyatsorongeka, uye mhando isingaenzaniswi neTIG neMIG welding yechinyakare.

Kupinza neLaser kunoshandisa chiedza chakasimba kuti chinyungudike uye chibatanidze simbi isingatsvi nekupisa kushoma, kunodzorwa. Maitiro aya anonyatso shandiswa anogadzirisa zvakananga matambudziko makuru ekukanganiswa kwekupisa uye huwandu hweweld.

Mabhenefiti Akakosha eLaser Welding Stainless Steel:

-

Kumhanya Kunoshamisa:Inoshanda nekukurumidza ka4 kusvika ku10 kupfuura TIG welding, zvichiwedzera kugona uye kugona kwayo zvakanyanya.

-

Kusawirirana Kushoma:Kupisa kwakanyatsogadzirwa kunoita kuti pave nenzvimbo diki diki ine njodzi pakupisa (HAZ), iyo inoderedza kana kubvisa kutenderera zvakanyanya, ichichengetedza kururama kwechikamu.

-

Hunhu Hwepamusoro:Inogadzira ma weld akachena, akasimba, uye anofadza runako ayo asingade kukuya kana kupedzisa mushure mekuweldwa.

-

Zvinhu Zvakachengetedzwa:Kupisa kushoma kunochengetedza simba resimbi isingatsvi uye kuramba ngura zvakanyanya, zvichidzivirira matambudziko akadai se "kuora kwesimbi".

Gwaro iri rinopa ruzivo rwehunyanzvi runodiwa kuti ubve pakunzwisisa kwekutanga kuenda pakushandisa zvine chivimbo, zvichiita kuti ugone kushandisa zvese zvinogona kuitwa nenzira iyi yekugadzira yepamusoro.

Kushongedza neLaservs. Nzira dzechinyakare: Kuenzanisa pakati pemunhu nemunhu

Kusarudza nzira chaiyo yekuwelda kwakakosha kuti chirongwa chibudirire. Heino maitiro ewelding nelaser anoenzaniswa neTIG neMIG pakushandisa simbi isingatsvi.

Kushongedza neLaser vs. Kushongedza neTIG

Kuwelda kweTungsten Inert Gas (TIG) kunozivikanwa nekuwelda kwemhando yepamusoro, nemaoko asi kunonetsa kufambirana nemamiriro ezvinhu ekugadzira.

-

Kumhanya & Kubudirira:Kucheka neLaser kunokurumidza zvikuru, zvichiita kuti ive sarudzo yakajeka yekugadzira otomatiki uye yakawanda.

-

Kupisa & Kukanganiswa:TIG arc inzvimbo yekupisa isingashande zvakanaka uye inopararira inogadzira HAZ yakakura, zvichikonzera kukanganiswa kukuru, kunyanya pasimbi yakatetepa. Danda rakatarisana nelaser rinodzivirira kukuvara uku kwakapararira kwekupisa.

-

Kuzvigadzira otomatiki:Masisitimu eLaser ari nyore kushandisa otomatiki, zvichiita kuti kugadzirwa kwemagetsi kuve kwakawanda uye kunodzokororwa pasina hunyanzvi hunodiwa nemaoko hunodiwa kupfuura TIG.

Kushongedza neLaser vs. Kushongedza neMIG

Kubatanidza Metal Inert Gas (MIG) inzira inoshandiswa zvakasiyana-siyana, inoiswa zvakanyanya, asi haina kunyatsojeka selaser.

-

Kunyatsorongeka & Hunhu:Kupinza neLaser inzira isingabatanidzi vanhu inoita kuti pave nekupinza kwakachena, kusina kusvibisa. Kupinza neMIG kunowanzo sanganisa nekupinza kunoda kucheneswa mushure mekupinza.

-

Kushivirira Kwemukana:Kusonta kweMIG kunorerutsira zvakanyanya kana majoini asina kugadzikana zvakanaka nekuti waya yayo inodyiwa inoshanda sefiller. Kusonta kweLaser kunoda kurongeka kwakanyatsojeka uye kushivirira kwakasimba.

-

Ukobvu hwezvinhu:Kunyange zvazvo ma laser ane simba guru achigona kubata zvikamu zvakakora, MIG inowanzo shanda zvakanyanya pa plate inorema zvikuru. Kubatanidza ma laser kunoshanda zvakanaka pahukobvu hwezvinhu zvakatetepa kusvika pakati nepakati apo kudzora kukanganisa kwakakosha.

Tafura Yekuenzanisa Pakutarisa

| Chinhu | Kukwevera kweLaser Beam | Kushongedza kweTIG | Kushongedza kweMIG |

| Kumhanya Kwekushongedza | Yakakwira Zvikuru (4-10x TIG)

| Zvakaderera Zvikuru | Yakakwirira |

| Nzvimbo Inokonzerwa Nekupisa (HAZ) | Zvishoma / Zvakanyanya Kupfupika | Yakafara | Yakafara |

| Kukanganiswa kwekupisa | Hazvina basa | Yakakwirira | Pakati Nepakati kusvika Pamusoro |

| Kushivirira Kwemukana | Yakaderera Zvikuru (<0.1 mm) | Yakakwirira | Zviri pakati nepakati |

| Mbiri Yekunamira | Yakamanikana & Yakadzika | Yakafara & Isina Kudzika | Yakafara & Inoshanduka-shanduka |

| Mutengo weMidziyo Yekutanga | Yakakwirira Zvikuru | Zvakaderera

| Yakaderera kusvika Pakati Nepakati

|

| Zvakanakira | Kunyatsojeka, kumhanya, otomatiki, zvinhu zvitete

| Basa remaoko remhando yepamusoro, runako

| Kugadzirwa kwakajairika, zvinhu zvakakora |

Sainzi Iri Kuseri Kwekunamira: Tsananguro Yenheyo Huru

Kunzwisisa kuti laser inoshanda sei nesimbi isingatsvi ndicho chinhu chikuru pakunzwisisa maitiro acho. Inoshanda nenzira mbiri dzakasiyana dzinoenderana nehuwandu hwesimba.

Nzira yeKufambisa vs. Nzira yeKeyhole

-

Kukwevera kweConduction:Kana simba rayo rakaderera, laser inopisa pamusoro pechinhu chacho, uye kupisa "kunopinza" muchikamu chacho. Izvi zvinogadzira weld isina kudzika, yakafara, uye yakapfava, yakakodzera zvinhu zvitete (pasi pe 1-2 mm) kana misono inooneka apo chitarisiko chakakosha.

-

Kupinza kweKiyi (Kupinda Mukati)Pakuwanda kwesimba (inenge 1.5 MW/cm²), laser inobvisa simbi ipapo ipapo, ichigadzira gomba rakadzika, rakamanikana rinonzi "kiyihole." Iri gomba rekiyi rinobata simba re laser, richiriendesa mukati mechinhu chacho kuti ripinze simba rakasimba, rakakwana muzvikamu zvakakora.

Mafungu Anoenderera Mberi (CW) vs. MaLaser Anopurwa

-

Mafungu Anoenderera Mberi (CW):Laser inopa simba risingaperi, risingachinjiki. Iyi nzira yakakwana yekugadzira misono mirefu, inoramba ichienderera mberi nekumhanya kwakanyanya mukugadzirwa otomatiki.

-

Laser Inopusha:Laser inopa simba munguva pfupi uye ine simba. Nzira iyi inopa kutonga kwakaringana pamusoro pekupisa, ichideredza HAZ uye ichiiita kuti ive yakakodzera kusanganisa zvinhu zvinodziya, zvinonzwa kupisa kana kugadzira ma "spot welds" anopindirana kuti zvive zvakanaka.

Nhungamiro Yekugadzirira Pasina Chikanganiso Danho Nedanho

Mukugadzira ne laser welding, kubudirira kunotarisirwa kuti danda risati ravhurwa. Kunyatsorongeka kwemaitiro acho kunoda kugadzirira kwakanyatsonaka.

Danho 1: Kugadzira uye Kugadzirisa Majoini

Kusiyana nekukwesha kwearc, welding nelaser hainyanyi kushivirira mipata kana kusarongeka zvakanaka.

-

Mhando dzeMajoini:Majoini epamagaro ndiwo anonyanya kushanda asi anoda mukaha uri pedyo ne zero (kazhinji pasi pe 0.1 mm kune zvikamu zvitete). Majoini epamagaro anorerutsira zvikuru kusiyana kwezvimiro zvekukwana.

-

Kudzora Musiyano:Mukana wakawandisa unodzivirira dziva diki rakanyungudutswa kuti risabatanidza mubatanidzwa, zvichikonzera kuti kubatanidza kusina kukwana uye weld isina kusimba. Shandisa nzira dzekucheka dzakarurama uye kubatanidza zvakasimba kuti uve nechokwadi chekuti wakarongeka zvakakwana.

Danho rechipiri: Kuchenesa Pamusoro uye Kubvisa Zvinosvibisa

Simba guru re laser rinoita kuti chero tsvina iri pamusoro ipfuure, richiibata mu weld uye zvichikonzera zvikanganiso zvakaita semaburi.

-

Kuchena Kwakakosha:Pamusoro payo panofanira kunge pasina mafuta, mafuta, guruva, uye zvinonamira.

-

Nzira Yekuchenesa:Pukuta nzvimbo yemajoini nejira risina jira rakanyikwa muchinhu chinonyunguduka senge acetone kana 99% isopropyl alcohol usati wabatanidza.

Kugona Muchina: Kugadzirisa Maparamita Akakosha Ekushongedza

Kuwana weld yakakwana kunoda kuyera zvinhu zvakasiyana-siyana zvakabatana.

Parameter Triad: Simba, Kumhanya, uye Nzvimbo Yekutarisa

Magadzirirwo matatu aya pamwe chete anosarudza simba rinopinda uye weld profile.

-

Simba reLaser (W):Simba guru rinoita kuti zvinhu zvipinde zvakadzika uye zvimhanye nekukurumidza. Zvisinei, simba rakawandisa rinogona kukonzera kupiswa kwezvinhu zvitete.

-

Kumhanya Kwekushongedza (mm/s):Kumhanya nekukurumidza kunoderedza kupisa uye kukanganisa. Kana kumhanya kwakanyanya kupfuura simba, zvinogona kukonzera kupinda kusina kukwana.

-

Nzvimbo Yekutarisa:Izvi zvinogadzirisa saizi yenzvimbo yelaser uye huwandu hwesimba rayo. Kutarisa pamusoro kunogadzira weld yakadzika uye yakamanikana. Kutarisa pamusoro pepamusoro (positive defocus) kunogadzira weld yakafara uye isina kudzika yezvishongo. Kutarisa pasi pepamusoro (negative defocus) kunogona kuwedzera kupinda kwezvinhu zvakakora.

Kusarudzwa kweGasi Rinodzivirira: Argon vs. Nitrogen

Gasi rekudzivirira rinodzivirira dziva resimbi rakanyungudutswa kubva mukusvibiswa kwemhepo uye rinodzikamisa maitiro acho.

-

Argon (Ar):Sarudzo inonyanya kushandiswa, inopa dziviriro yakanaka uye kugadzira welds dzakagadzikana uye dzakachena.

-

Nitrogen (N2):Kazhinji inofarirwa kushandiswa nesimbi isingatsvi, sezvo ichigona kuwedzera ngura yejoini rekupedzisira.

-

Mwero wekuyerera:Mwero wekuyerera kwemvura unofanira kugadziriswa. Kuwanda kwemvura hakuzokwanisi kudzivirira weld, nepo kuwanda kwayo kuchigona kukonzera kutenderera uye kukwezva tsvina. Mwero wekuyerera kwemvura wemarita gumi kusvika makumi maviri nemashanu paminiti (L/min) ndiwo mavambo akajairika.

Nzvimbo Dzekutanga dzeParamende: Tafura Yekutarisa

Izvi zvinotevera ndizvo zvinotangira pakunamira simbi isingatsvinda ye304/316 austenitic. Gara uchiyedza zvinhu zvakaraswa kuti ugadzirise zvaunoda.

| Ukobvu hwezvinhu (mm) | Simba reLaser (W) | Kumhanya Kwekushongedza (mm/s) | Nzvimbo Yekutarisa | Gasi rekudzivirira |

| 0.5 | 350 - 500 | 80 - 150 | Pamusoro | Argon kana Nitrogen |

| 1.0 | 500 – 800 | 50 - 100 | Pamusoro | Argon kana Nitrogen |

| 2.0 | 800 – 1500 | 25 - 60 | Pasi pevhu zvishoma | Argon kana Nitrogen |

| 3.0 | 1500 - 2000 | 20 - 50 | Pasi pevhu | Argon kana Nitrogen |

| 5.0 | 2000 - 3000 | 15 - 35 | Pasi pevhu | Argon kana Nitrogen |

Kudzora Hunhu: Gwaro Rekugadzirisa Matambudziko Ezvinhu Zvakajairika

Kunyangwe kana nzira yacho yakanyatsorongeka, zvikanganiso zvinogona kuitika. Kunzwisisa chikonzero chazvo ndicho chinhu chikuru chekudzivirira.

Kuziva Zvikanganiso Zvakajairika zveLaser Welding

-

Kuboorwa kwemvura:Mafuro madiki egasi akabatwa mu weld, anowanzo kukonzerwa nekusvibiswa kwepamusoro kana kuyerera kwegasi kusina kusimba.

-

Kupwanya Kunopisa:Mitsemhere yepakati inoumbwa sezvo weld ichioma, dzimwe nguva nekuda kwekugadzirwa kwezvinhu kana kushushikana kwakanyanya kwekupisa.

-

Kupinda Kusina Kukwana:Weld inotadza kubatana nepakati pehudzamu hwese hwejoinhi, kazhinji nekuda kwesimba risina kukwana kana kumhanya kwakanyanya.

-

Kuchekwa zvishoma:Mugero wakanyungudika musimbi yepasi pamucheto we weld, kazhinji zvichikonzerwa nekumhanya kwakanyanya kana mukaha mukuru.

-

Kuparadzira:Madonhwe akanyunguduka anobuda mudziva rekunamira, kazhinji nekuda kwesimba rakawandisa kana kusvibiswa pamusoro.

Chati Yekugadzirisa Matambudziko: Zvinokonzera uye Mhinduro

| Chirema | Zvingangove Zvikonzero | Matanho Ekugadzirisa Anokurudzirwa |

| Kuboorwa kwemvura | Kusvibiswa pamusoro; kuyerera kwegasi kusina kusimba. | Shandisai nzira dzakasimba dzekuchenesa usati waisa weld; ongororai gasi rakakodzera uye wedzerai mwero wekuyerera kwemvura. |

| Kutsemuka Kunopisa | Zvinhu zvinokanganisa; kushushikana kwakanyanya kwekupisa. | Shandisa waya yakakodzera yekuzadza; pisa zvinhu zvacho kuti uderedze kupisa. |

| Kupinda Kusina Kukwana | Simba risipo; kumhanya zvakanyanya; kusanyatsotarisa zvakanaka. | Wedzera simba relaser kana kuderedza kumhanya kwekuwelda; simbisa uye gadzirisa nzvimbo yekutarisa. |

| Kuchekwa zvishoma | Kumhanya kwakanyanya; mukaha mukuru wemajoini. | Deredza kumhanya kwekupinza; gadzirisa kugadzika kwezvikamu kuti uderedze mukaha. |

| Kuparadzira | Kuwanda kwesimba; kusvibiswa pamusoro. | Deredza simba relaser kana kushandisa nzira yekubvisa focus; iva nechokwadi chekuti nzvimbo dzakachena zvakakwana. |

Matanho Ekupedzisira: Kuchenesa Mushure meWeld uye Passivation

Maitiro ekunamira simbi anokuvadza zvinhu zvinoita kuti simbi isingasvibi "isasvibi." Kuigadzirisa idanho rekupedzisira rinosungirwa.

Sei Usingakwanise Kusiya Kurapa Mushure meWeld

Kupisa kunobva pakusonwa kunoparadza chromium-oxide layer isingaoneki, inodzivirira pamusoro pesimbi. Izvi zvinoita kuti weld neHAZ yakapoteredza zvive nyore kubatwa nengura nengura.

Nzira dzeKushandura Zvinhu Zvisina Kunaka Dzakatsanangurwa

Passivation mushonga wemakemikari unobvisa tsvina pamusoro uye unobatsira kugadzirisa chromium-oxide layer yakasimba, yakafanana.

-

Kutora Makemikari:Nzira yechinyakare inoshandisa maasidhi ane njodzi senge nitric ne hydrofluoric acid kuchenesa nekubvisa mvura pamusoro.

-

Kuchenesa Nemagetsi:Nzira yemazuva ano, yakachengeteka, uye inokurumidza inoshandisa mvura ine electrolytic yakapfava uye simba remagetsi rakaderera kuchenesa nekunyaradza weld nedanho rimwe chete.

Kuchengetedza Kutanga: Kungwarira Kwakakosha Pakushongedza NeLaser

Kushandiswa kwe laser welding nesimba rakawanda kunounza njodzi huru pabasa dzinoda mitemo yakasimba yekuchengetedza.

Njodzi Yakavanzika: Utsi hweChromium (Cr(VI)) Hwehesi

Kana simbi isingasvibi ikadziiswa kusvika pakupisa kwekunamira, chromium iri mu alloy inogona kugadzira hexavalent chromium (Cr(VI)), iyo inobhururuka mumhepo muutsi.

-

Njodzi dzehutano:Cr(VI) inozivikanwa sekenza yevanhu inokonzerwa nekuwedzera kwenjodzi yekenza yemapapu. Inogonawo kukonzera kutsamwa kwakanyanya kwekufema, ganda, uye maziso.

-

Miganhu Yokuratidzwa:OSHA inoisa muganho wakasimba wePermissible Exposure Limit (PEL) we5 micrograms pa cubic meter yemhepo (5 µg/m³) yeCr(VI).

Matanho Akakosha Ekuchengetedza

-

Kudzora Kweinjiniya:Nzira inonyanya kushanda yekudzivirira vashandi ndeyekubata njodzi yacho painobva.sisitimu yekubvisa utsiNefirita yeHEPA ine nhanho dzakawanda, zvakakosha kuti ubate zvidimbu zvakapfava zvinogadzirwa ne laser welding.

-

Midziyo Yekudzivirira Munhu Pachake (PPE):Vashandi vese vari munzvimbo iyi vanofanira kupfeka magirazi ekudzivirira elaser akatarwa zvichienderana nehurefu hwewavelength yelaser. Kana kubvisa utsi kusingakwanise kuderedza kusvibiswa kuri pasi pePEL, ma respirators anotenderwa anodiwa. Kushanda kwe welding kunofanirwawo kuitwa mukati menzvimbo isingapindi chiedza ine makiyi ekuchengetedza kudzivirira kusvibiswa netsaona.

Mibvunzo Inowanzo bvunzwa (Mibvunzo Inowanzo bvunzwa)

Ndeipi mhando yelaser yakanakisisa yekushongedza simbi isina ngura?

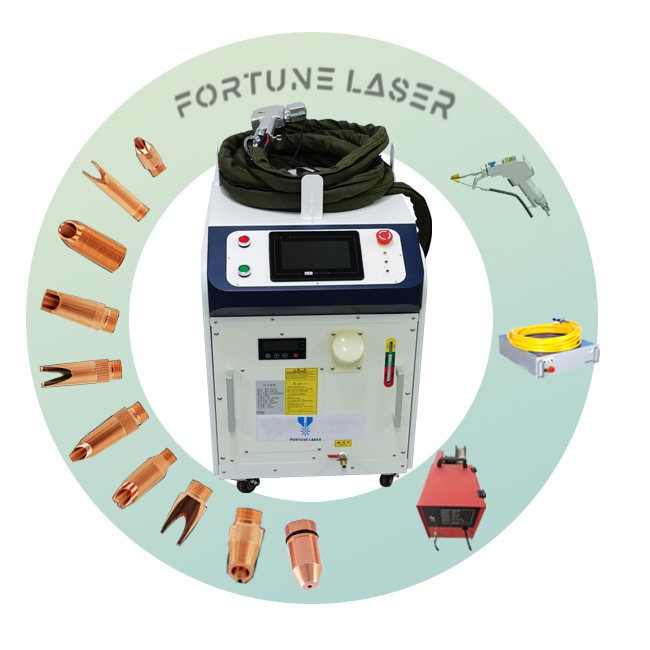

Malaser efaibha kazhinji ndiwo anonyanya kusarudzwa nekuda kwehurefu hwawo hwemafungu, hunogona kunyudzwa nyore nyore nesimbi isingatsvi, uye hunhu hwawo hwakanaka hwemwenje kuti unyatso dzora.

Unogona here kusanganisa simbi isina ngura ne laser pamwe chete nehukobvu hwakasiyana?

Ehe, kupinza ne laser kunoshanda zvikuru pakubatanidza ukobvu hwakasiyana pasina kukanganisa kwakanyanya uye pasina kutsva-kupfuura pachikamu chakatetepa, basa rakaoma zvikuru nekupinza neTIG.

Waya yekuzadza inodiwa here pakushongedza simbi isina ngura ne laser?

Kazhinji, kwete. Kubatanidza nelaser kunogona kugadzira ma weld akasimba, anopinda zvizere pasina zvinhu zvekuzadza (autogenously), izvo zvinoita kuti maitiro acho ave nyore. Waya yekuzadza inoshandiswa kana dhizaini yejointi iine mukaha mukuru kana kana paine hunhu hwakati hwesimbi hunodiwa.

Upfu hwakanyanya sei hwesimbi isingatsvi inogona kusvetwa nelaser?

Nemasystem ane simba guru, zvinokwanisika kusanganisa simbi isingasvibi kusvika 1/4″ (6mm) kana kutokora kamwe chete. Maitiro e hybrid laser-arc anogona kusanganisa zvikamu zvinopfuura 1 inch ukobvu.

Mhedziso

Kubatsira kweLaser welding mukumhanya, kunyatsorongeka, uye kunaka kunoita kuti ive sarudzo yepamusoro yekugadzira simbi dzisina ngura dzemazuva ano. Inogadzira majoini akasimba, akachena asina kukanganiswa zvakanyanya, zvichichengetedza kunaka kwechigadzirwa uye chitarisiko.

Zvisinei, kuwana mhedzisiro iyi yepamusoro-soro kunoenderana nenzira yakazara. Kubudirira ndiko kuguma kwecheni yekugadzira yakanyatsogadzirwa—kubva pakugadzirira kwakanyatsonaka pamwe chete uye kudzora maparamendi zvakarongeka kusvika pakumanikidzwa kwepasi mushure mekuweld uye kuzvipira kusingazununguki kukuchengetedza. Nekuziva maitiro aya, unogona kuvhura nhanho itsva yekushanda zvakanaka uye mhando mumabasa ako.

Nguva yekutumira: Gumiguru-08-2025