1.Kushongedza kwakanyatsogadzirwa:Michina yekubatanidza yerobhoti nelaser inogona kusanganisa michina nemazvo, uye mhando yekubatanidza michina iyi yakagadzikana uye yakavimbika. Inoshandiswawo zvakanyanya mukugadzira nekugadzirisa michina.

2.Kushanda nesimba zvakanyanya uye kuchengetedza simba:Sezvo muchina wekubatanidza werobhoti uchishandisa laser usingashandise simba rakawanda kupedzisa basa rekubatanidza, une mabhenefiti makuru panyaya yekuchengetedza simba. Zvakare zviri nyore kuchengetedza kana uchishanda kwenguva yakareba.

3.Kugadzirwa nekukurumidza:Michina yekubatanidza marobhoti nelaser inogona kupedzisa mabasa akawanda ekubatanidza marobhoti munguva pfupi, uye ine mabhenefiti makuru pakumhanya. Uye sezvo maitiro ekubatanidza marobhoti achiitwa nemarobhoti, kushanda zvakanaka kwekubatanidza marobhoti kwakakwira.

MaParamende Makuru eUnyanzvi emuchina we robot laser welding

1. Robhoti

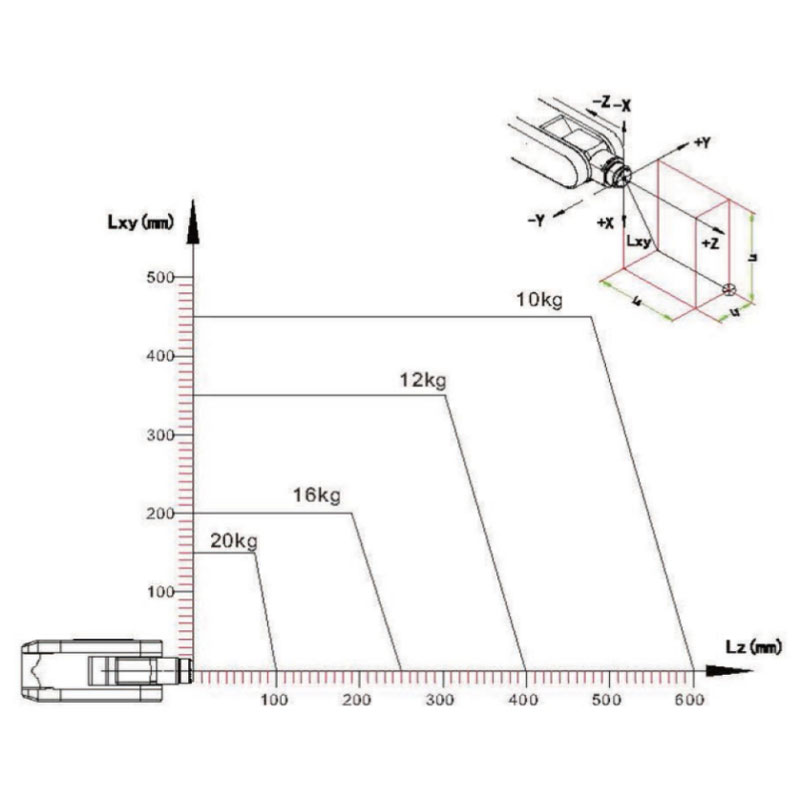

Girafu yemutoro werobhoti:

Saizi uye nhanho yezviito. Chikamu: mm

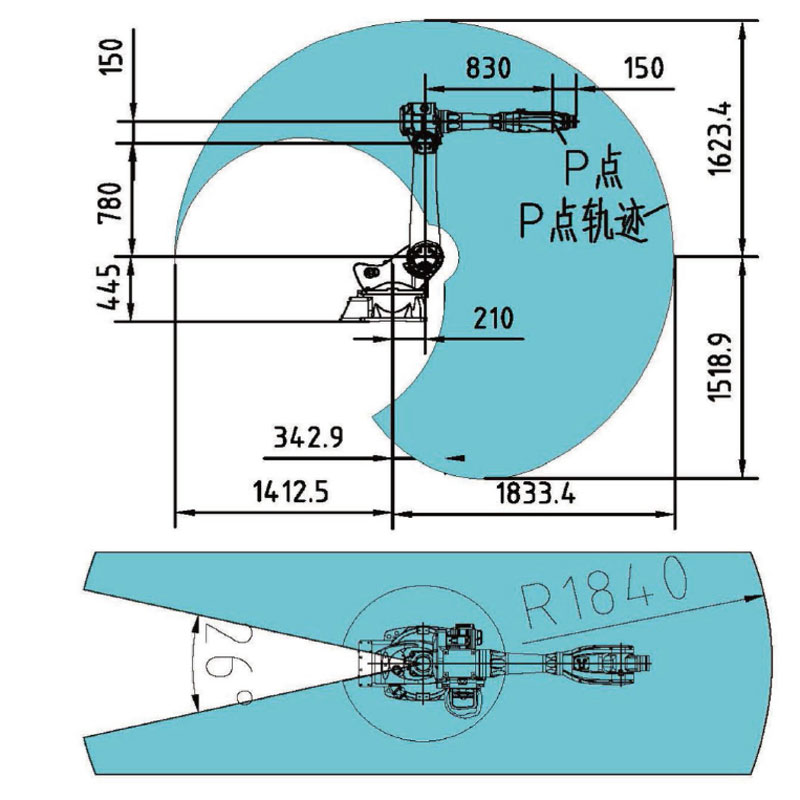

Nzvimbo yeP point action

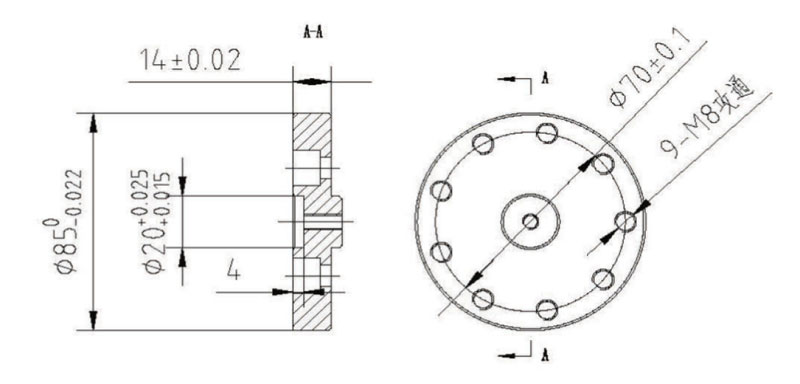

Zviyero zvekuisa flange yekupedzisira.

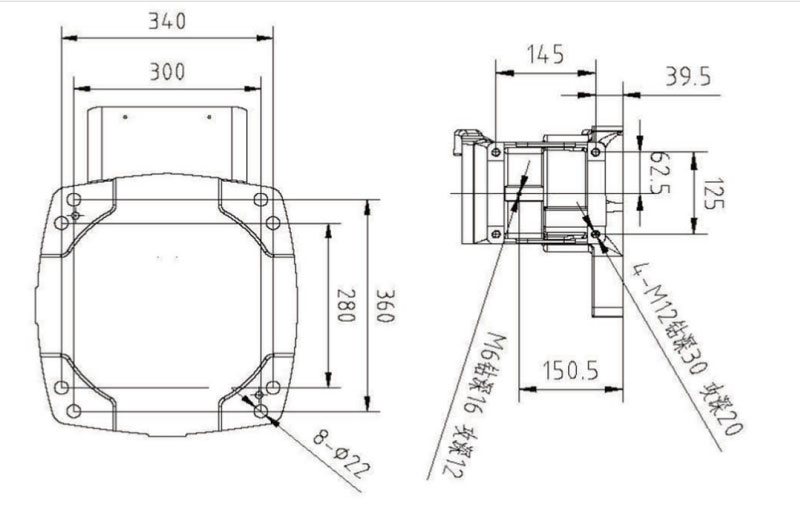

Zviyero zvekutanga zvekuisa Saizi yekuisirwa ine mativi mana