Muchina weFortune Laser Automatic 1000W/1500W/2000W Fiber Laser Inoramba Ichienderera Pachikuva Welding Machine

Muchina weFortune Laser Automatic 1000W/1500W/2000W Fiber Laser Inoramba Ichienderera Pachikuva Welding Machine

Nheyo dzekutanga dzeMuchina weLaser

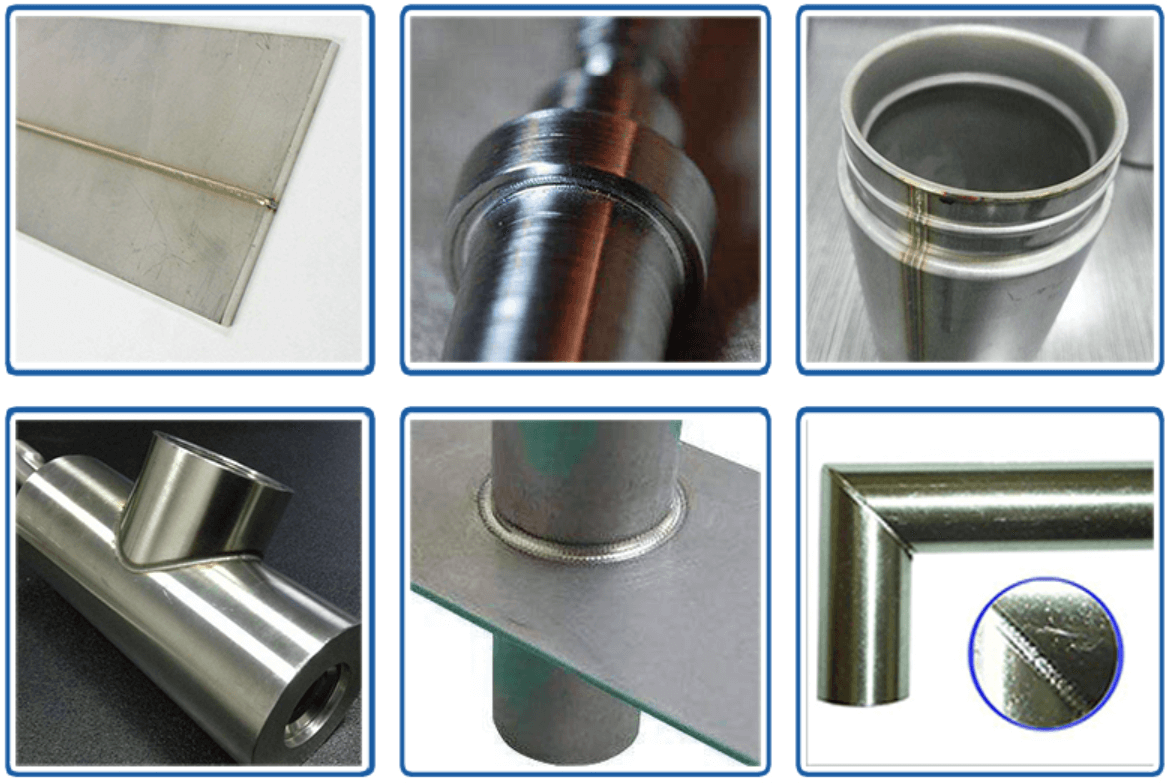

Muchina wekubatanidza fiber laser unoenderera mberi imhando itsva yenzira yekubatanidza. Kazhinji unoumbwa ne "welding host" uye "welding workbench". Beam re laser rinosanganiswa ne optical fiber. Mushure mekutumirwa kure, rinogadziriswa kuita parallel light focusing. Continuous welding inoitirwa pa workpiece. Nekuda kwekuramba kwechiedza, welding effect inosimba uye weld seam inonaka uye yakanaka. Zvichienderana nezvinodiwa zvakasiyana zvemaindasitiri akasiyana, michina ye laser welding inogona kuenderana nechimiro ne workbench zvichienderana nenzvimbo yekugadzira uye kuita otomatiki kushanda, izvo zvinogona kusangana zvizere nezvinodiwa nevashandisi mumaindasitiri akasiyana.

Michina yakawanda yekubatanidza fiber laser inoshandisa laser ine simba guru ine simba rinodarika mawatts 500. Kazhinji, laser dzakadaro dzinofanira kushandiswa pamaplates anopfuura 1mm. Muchina wayo wekubatanidza unopinza zvakadzika zvichibva pamhedzisiro yegomba diki, une chiyero chikuru chekudzika kusvika paupamhi, chinogona kusvika kupfuura 5:1, kumhanya kwekubatanidza nekukurumidza, uye kushanduka kudiki kwekushisa.

1000W 1500w 2000w Kuenderera mberi Laser Welding Machine hunhu

Fortune Laser Inoenderera Mberi Laser Welding Machine Technical Parameters

Zvishongedzo

1. Chitubu cheLaser

2. Tambo yeLaser yeFiber

3. Musoro wekushongedza weQBH nelaser

4. Chiller che 1.5P

5. PC uye sisitimu yekuwedera

6. 500*300*300 Linear Rail Servo Electric Translation Stage

7. Sisitimu yekudzora ine mativi mana 3600

8. Sisitimu yekamera yeCCD

9. Kabhineti reMainframe