Kodi makina ochapira laser amagwira ntchito bwanji?

Makina ochapira pogwiritsa ntchito laser amagwiritsa ntchito mphamvu zambiri za laser pulse kuti atenthetse zinthu zomwe ziyenera kukonzedwa pang'ono, ndipo pamapeto pake amasungunula kuti apange dziwe losungunuka, lomwe limatha kupangitsa kuti pakhale malo ochapira, kuchapa pogwiritsa ntchito matako, kuchapa pogwiritsa ntchito lap, kutseka pogwiritsa ntchito sealing welding, ndi zina zotero. Ubwino wake wapadera umatsegula malo atsopano ogwiritsira ntchito laser welding, kupereka kuchapa kolondola kwa zipangizo zokhala ndi makoma ochepa komanso tinthu tating'onoting'ono.

Kodi makina ochapira laser amagwiritsidwa ntchito pa chiyani?

1. Kuwotcherera

Cholinga chachikulu cha makina ochapira a laser mosakayikira ndikuchapira. Sichingothamangitsira zinthu zachitsulo zopyapyala monga mbale zachitsulo zosapanga dzimbiri, mbale za aluminiyamu, ndi mbale zagalasi, komanso chingagwiritsidwe ntchito pochapira zitsulo zapepala, monga ziwiya zakukhitchini. Ndi yoyenera kuchapa chathyathyathya, chowongoka, cha arc ndi kuchapa kwa mawonekedwe aliwonse kumagwiritsidwa ntchito kwambiri mumakina olondola, zodzikongoletsera, zida zamagetsi, mabatire, mawotchi, kulumikizana, ntchito zamanja ndi mafakitale ena. Imatha kumaliza kuchapa bwino m'malo osiyanasiyana ovuta ndipo imakhala ndi mphamvu zambiri zopangira. Poyerekeza ndi kuchapa kwa argon arc kwachikhalidwe ndi kuchapa kwamagetsi, njira zina zimakhala ndi zabwino zambiri.

Pogwiritsa ntchito makina ochapira pogwiritsa ntchito laser, msoko wochapira uli ndi m'lifupi mwake, kuya kwakukulu, malo ang'onoang'ono otenthetsera kutentha, kusintha pang'ono, msoko wochapira wosalala komanso wokongola, mtundu wapamwamba wa kuwotcherera, palibe mabowo a mpweya, kuwongolera kolondola, mtundu wokhazikika wa kuwotcherera, palibe chifukwa chochizira kapena chithandizo chosavuta mutawotcherera.

2. Kukonza

Kugwiritsa ntchito makina ochapira a laser sikungokhudza kuwotcherera, komanso kukonza kuwonongeka, chilema, kukanda kwa nkhungu, ndi dzenje la mchenga, ming'alu, kusintha kwa mawonekedwe ndi zolakwika zina za chitsulo chogwirira ntchito. Nkhunguyo idzatha pambuyo pa nthawi yayitali yogwiritsidwa ntchito. Ngati itatayidwa mwachindunji, kutayika kwake kudzakhala kwakukulu. Nkhungu yovuta ingagwiritsidwenso ntchito mokwanira pokonzanso nkhungu yovuta kudzera mu makina ochapira a laser, makamaka pokonza pamwamba pake, kupewa mavuto awiri a kutentha ndi chithandizo chomaliza pambuyo pa kuwotcherera. Njira imodzi, yopulumutsa kwambiri nthawi yopanga ndi ndalama zopangira.

Kodi makina ochapira laser ali ndi njira yotani yochapira?

1. Kuwotcherera pakati pa zidutswa

Kuphatikizapo kuwotcherera matako, kuwotcherera kumapeto, kuwotcherera pakati, ndi kuwotcherera pakati.

2. Kuwotcherera waya kuchokera ku waya kupita ku waya

Kuphatikizapo kuwotcherera matako a waya ndi waya, kuwotcherera kopingasa, kuwotcherera kozungulira panjira, ndi kuwotcherera kofanana ndi T.

3. Kuwotcherera waya wachitsulo ndi zigawo za block

Kuwotcherera kwa laser kumatha kulumikiza bwino waya wachitsulo ndi zigawo za block, ndipo kukula kwa zigawo za block kungakhale kopanda tsankho. Chisamaliro chiyenera kuperekedwa ku miyeso ya geometrical ya zinthu za filamentary panthawi yowotcherera.

4. Kuwotcherera zitsulo zosiyanasiyana

Kuwotcherera zitsulo zamitundu yosiyanasiyana kumakhudza kuchuluka kwa zinthu zomwe zingathe kuwotcherera komanso zomwe zingathe kuwotcherera. Kuwotcherera kwa laser pakati pa zipangizo zosiyanasiyana kumatheka kokha ndi kuphatikiza zinthu zina.

Kodi mungasankhe bwanji gwero loyenera la laser?

Gwero la laser la Yg:

Chitsulo cha pepala, zolumikizira zodzikongoletsera zagolide, makina oyeretsera a titaniyamu, masamba olumikizira lumo ndi laser yozungulira.

Mtundu uwu wa laser umaletsa chitsulo kuti chisasungunuke kapena kusokonekera.

Za zitsulo zopyapyala komanso zopepuka.

Gwero la laser la CW:

Izi ndi zodula kwambiri poyerekeza ndi ma laser oyendetsedwa ndi pulsed. Zimachepetsanso ndalama zogwirira ntchito.

Yogwira ntchito kwambiri pa zitsulo zotsutsa.

Akulimbikitsidwa kulumikiza ziwalo zokhuthala.

Zingayambitse mavuto ngati zigwiritsidwa ntchito pa chitsulo kapena zigawo zoonda kwambiri. Pankhaniyi, laser ikhoza kuwononga, kusungunula kapena kuwononga gawolo.

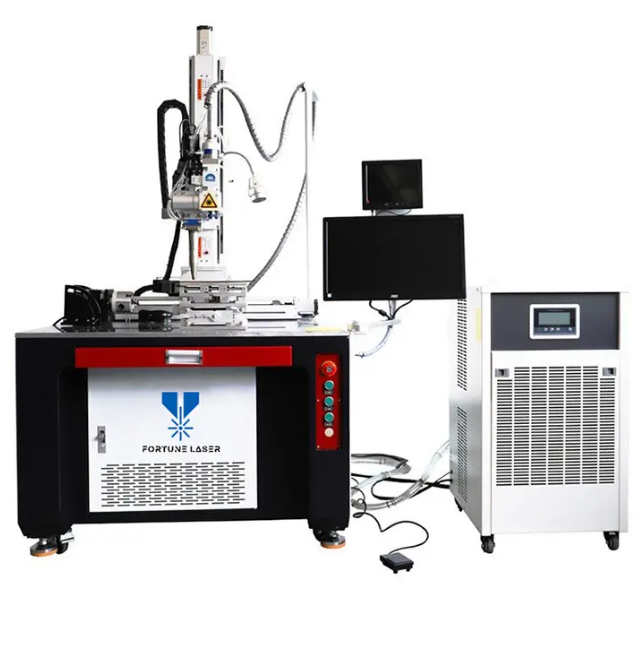

Ndi mitundu yanji ya makina ochapira omwe alipo onse?

Makina ochapira pogwiritsa ntchito laser amadziwikanso kuti makina ochapira pogwiritsa ntchito laser komanso makina ochapira pogwiritsa ntchito laser. Magulu ake ndi awa:

1. Makina owotcherera a laser ogwiritsidwa ntchito m'manja:

Mwina iyi ndi mtundu wa zida zowotcherera zomwe zimapezeka kwambiri pamsika. Nthawi zambiri zimagwiritsidwa ntchito powotcherera mapepala osiyanasiyana achitsulo.

2. Makina owotcherera a laser:

Itha kugwiritsidwa ntchito popanga zodzikongoletsera zagolide ndi siliva, kudzaza mabowo a zida zamagetsi, mabala owotcherera, zophimba zolumikizira, ndi zina zotero.

3. Makina owotcherera a laser okha:

Ndi yoyenera kulumikiza mizere yowongoka ndi yozungulira ya zitsulo, ndipo nthawi zambiri imagwiritsidwa ntchito m'mafakitale monga mabatire a foni yam'manja, zodzikongoletsera, zida zamagetsi, masensa, mawotchi ndi mawotchi, makina olondola, kulumikizana, ndi ntchito zamanja.

4. Makina owotcherera a laser:

Amagwiritsidwa ntchito makamaka pokonza nkhungu m'mafakitale opanga ndi kuumba nkhungu monga mafoni am'manja, zinthu zama digito, magalimoto ndi njinga zamoto, ndipo amagwiritsidwanso ntchito kwambiri powotcherera ndi manja.

5. Makina owotcherera a laser opangidwa ndi ulusi wowala:

Pazigawo zomwe zimakhala zovuta kupeza kuti zigwiritsidwe ntchito powotcherera, kuwotcherera kosakhudzana ndi ma transmission osinthasintha kumachitika, komwe kumakhala kosinthasintha kwambiri. Kuwala kwa laser kumatha kugawa nthawi ndi mphamvu, ndipo kumatha kukonza ma dayamondi angapo nthawi imodzi, zomwe zimapangitsa kuti zikhale zosavuta kuwotcherera.

6. Makina owotcherera a laser a galvanometer a fiber optical fiber:

Kuphatikiza kwabwino kwa makina oyendera a galvanometer ndi makina olumikizira a laser. Kusunga bwino nthawi yopanda kanthu yoyikirapo panthawi yolumikizira malo amodzi, ndikuwonjezera magwiridwe antchito ndi nthawi 3-5 poyerekeza ndi benchi lamagetsi lachikhalidwe.

Chiyambi cha mitundu yeniyeni ya makina owotcherera:

Makina owotcherera a laser ogwiritsidwa ntchito ndi manja

Zipangizo zodziwika bwino zokonzera zitsulo za laser pamsika ndi makina ochapira a laser ogwiritsidwa ntchito m'manja. Mu zida zochapira zachikhalidwe, kuphatikiza kwa luso lochapira ndi ukadaulo ndizofunikira kuti zikwaniritse kupanga tsiku ndi tsiku, ndipo liwiro lake ndi lochepa, ndipo mawonekedwe a chochapira amafunika kupukutidwa pambuyo pake. Kukonza kumatenga nthawi yambiri komanso ntchito yovuta.

Chiyambi cha chitsanzo: Gwiritsani ntchito ulusi wowala kuti mutumize laser, ndikuyika kuwala kwa laser mwachindunji pa gawo lolumikizira kudzera mu mfuti yopopera yogwira m'manja. Ili ndi mawonekedwe olondola kwambiri, ogwira ntchito bwino komanso malo otsika kutentha, ndipo ndi yoyenera kuwotcherera zigawo zazing'ono, zovuta kapena zovuta kufikira.

Ubwino waukulu:

1 Ntchitoyi ndi yosavuta, palibe chidziwitso chaukadaulo chaukadaulo chofuna kuwotcherera chomwe chikufunika, ndipo ntchitoyi ikhoza kuyambika patatha maola awiri a maphunziro osavuta.

2 Liwiro la kuwotcherera ndi lachangu kwambiri, ndipo chowotcherera cha laser chogwiritsidwa ntchito m'manja chingathe kusintha mphamvu ya owotcherera wamba atatu kapena asanu.

3 Kuwotcherera kungakhale kopanda zinthu zogwiritsidwa ntchito, zomwe zimapulumutsa ndalama zogulira.

4 Pambuyo poti kuwotcherera kwatha, msoko wowotcherera umakhala wowala komanso woyera, ndipo ukhoza kuchitika popanda kupukutidwa.

5. Mphamvu ya makina ochapira laser imakhala yochuluka, kutentha kwake kumakhala kochepa, ndipo chinthucho sichimawonongeka mosavuta.

6 Mphamvu ya makina ochapira laser imakhala yochuluka, ndipo mphamvu ya makina ochapira ndi yokwera kwambiri.

7. Mphamvu ndi mphamvu ya makina ochapira laser zimayendetsedwa ndi digito, zomwe zimatha kukwaniritsa zofunikira zosiyanasiyana zochapira, monga kulowa kwathunthu, kulowa, kuwotcherera malo ndi zina zotero.

Zipangizo zomwe zimagwiritsidwa ntchito ndi ntchito zamakampani: zimagwiritsidwa ntchito makamaka muzipangizo zamagetsi, zida zamagalimoto, zida, makina olondola, zida zolumikizirana ndi mafakitale ena zitsulo zosapanga dzimbiri, chitsulo cha kaboni, chitsulo cha silicon, aloyi ya aluminiyamu, aloyi ya titaniyamu, pepala lopangidwa ndi galvanized, pepala lopangidwa ndi galvanized, mkuwa, ndi zina zotero. Kuwotcherera mwachangu zipangizo zosiyanasiyana zachitsulo ndi kuwotcherera pakati pa zipangizo zina zosiyana.

Makina ochapira a laser okha - makina ochapira a laser okha okhala ndi miyeso iwiri

Chiyambi cha Chitsanzo:

Makinawa amagwiritsa ntchito chotchingira cha ceramic chokhala ndi nyali ziwiri chomwe chimatumizidwa kuchokera ku UK, ndi mphamvu yamphamvu, pulse yokonzedwa komanso kasamalidwe kanzeru ka dongosolo. Z-axis ya benchi yogwirira ntchito imatha kusuntha mmwamba ndi pansi pogwiritsa ntchito magetsi kuti iyang'ane, ndipo imayendetsedwa ndi PC yamakampani. Yokhala ndi tebulo loyenda lokhazikika la X/Y axis lokhala ndi magawo atatu. Chosinthira china chosankha (80mm kapena p 125mm chosankha) kuti chikwaniritse kuwotcherera kwa laser kokhazikika kwa magawo awiri. Dongosolo lowunikira limagwiritsa ntchito maikulosikopu, kuwala kofiira ndi CCD. Yokhala ndi makina ozizira amadzi akunja.

Ubwino waukulu:

1. Chipinda chosungiramo zinthu cha ceramic chokhala ndi nyali ziwiri chomwe chimatumizidwa kuchokera ku UK chimagwiritsidwa ntchito, chomwe chimapirira dzimbiri komanso kutentha kwambiri, ndipo nthawi ya moyo wa chipindacho ndi zaka 8-10.

2. Kuchita bwino kwa kupanga ndi kwakukulu, liwiro la kuwotcherera ndi lachangu, ndipo kupanga kwa mzere wolumikizira wokha kumatha kuchitika.

3. Mutu wa laser ukhoza kuzunguliridwa 360°, ndipo njira yonse yowunikira ikhoza kusunthidwa 360° ndikutambasulidwa mmbuyo ndi mtsogolo.

4. Kukula kwa malo owala kumatha kusinthidwa ndi magetsi.

5. Nsanja yogwirira ntchito ikhoza kusunthidwa ndi magetsi m'magawo atatu.

Zipangizo zogwiritsidwa ntchito ndi ntchito zamakampani:

Yoyenera ma ketulo, makapu otayira mpweya, mbale zachitsulo chosapanga dzimbiri, masensa, mawaya a tungsten, ma diode amphamvu kwambiri (ma transistors), ma alloy a aluminiyamu, ma casing a laputopu, mabatire a foni yam'manja, zogwirira zitseko, ma mold, zowonjezera zamagetsi, zosefera, ma nozzles, zinthu zosapanga dzimbiri, mutu wa gofu wa mpira, zaluso za zinc alloy ndi zina zowotcherera. Zithunzi zowotcherera zimaphatikizapo: mfundo, mizere yolunjika, mabwalo, mabwalo kapena zithunzi zilizonse zojambulidwa ndi pulogalamu ya AutoCAD.

Kuwotcherera kwa malo ang'onoang'ono a laser, kophatikizidwa pa kompyuta, kosiyana

Chiyambi cha Chitsanzo:

Makina ochapira malo a laser amagwiritsidwa ntchito makamaka pokonza mabowo ndi matuza ochapira malo a zodzikongoletsera zagolide ndi siliva. Kuchapira malo a laser ndi chimodzi mwa zinthu zofunika kwambiri pakugwiritsa ntchito ukadaulo wokonza zinthu za laser. Njira yochapira malo ndi yamtundu wa kutentha, ndiko kuti, kuwala kwa laser kumatenthetsa pamwamba pa chogwirira ntchito, ndipo kutentha kwa pamwamba kumafalikira mkati mwa chogwirira ntchito kudzera mu kutentha. Mwa kuwongolera m'lifupi, mphamvu, mphamvu yayikulu komanso kubwerezabwereza kwa kugunda kwa laser, Magawo monga kuchuluka kwa ma frequency amachititsa kuti chogwirira ntchito chisungunuke ndikupanga dziwe losungunuka. Chifukwa cha ubwino wake wapadera, chagwiritsidwa ntchito bwino pokonza zodzikongoletsera zagolide ndi siliva komanso kuchapa zinthu zazing'ono.

Zitsanzo:

Liwiro lachangu, kugwira ntchito bwino kwambiri, kuya kwakukulu, kusintha pang'ono, malo ang'onoang'ono okhudzidwa ndi kutentha, mtundu wapamwamba wa kuwotcherera, palibe kuipitsidwa kwa malo olumikizirana, kugwira ntchito bwino kwambiri komanso kuteteza chilengedwe.

Ubwino waukulu:

1. Mphamvu, m'lifupi mwa kugunda kwa mtima, pafupipafupi, kukula kwa malo, ndi zina zotero zitha kusinthidwa mkati mwa mtunda waukulu kuti zikwaniritse zotsatira zosiyanasiyana zowotcherera. Magawo amawongoleredwa ndikusinthidwa m'malo otsekedwa, zomwe ndi zosavuta komanso zothandiza.

2. Chipinda chosungiramo zinthu cha ceramic chomwe chimatumizidwa kuchokera ku United Kingdom chimagwiritsidwa ntchito, chomwe chimapirira dzimbiri, chimapirira kutentha kwambiri, komanso chimakhala ndi mphamvu zambiri zosinthira kuwala kwa dzuwa.

3. Gwiritsani ntchito njira yapamwamba kwambiri padziko lonse yodzitetezera yokha, yomwe imachotsa kuyabwa m'maso nthawi yantchito.

4. Ili ndi mphamvu yogwira ntchito mosalekeza kwa maola 24, makina onse ali ndi magwiridwe antchito okhazikika, ndipo sakukonza mkati mwa maola 10,000.

5. Kapangidwe ka umunthu, mogwirizana ndi ergonomics, kangagwire ntchito kwa nthawi yayitali popanda kutopa.

Makina Owotcherera a Laser Mold

Chiyambi cha Chitsanzo:

Makina ochapira nkhungu a laser ndi chitsanzo chapadera chopangidwira makampani opanga nkhungu. Makinawa amagwiritsidwa ntchito makamaka m'malo mwa makina ochapira a argon arc omwe amagwiritsidwa ntchito pokonza nkhungu molondola. Zigawo zofunika kwambiri za makinawa ndi zinthu zonse zochokera kunja. Mawonekedwe ogwiritsira ntchito mapulogalamuwa amagwiritsa ntchito chiwonetsero chachikulu cha kristalo chamadzimadzi, ndipo mawonekedwe ake ndi osavuta komanso omveka bwino, ndipo wogwiritsa ntchitoyo ndi wosavuta kuphunzira ndikugwiritsa ntchito. Mitundu yosiyanasiyana ya njira zogwirira ntchito zomwe zasungidwa kale zitha kukonzedwanso nokha, ndipo ntchito yosungiramo zinthu zakale ingagwiritsidwe ntchito pazinthu zosiyanasiyana.

Zitsanzo:

1. Malo omwe kutentha kumakhudza ndi ochepa ndipo sangayambitse kusintha kwa mawonekedwe olondola;

2. Kuzama kwa cholumikizira ndi kwakukulu ndipo cholumikizira ndi cholimba. Chisungunuka kwathunthu, osasiya zizindikiro zokonzanso. Palibe malo otsetsereka pakati pa gawo lokwezedwa la dziwe losungunuka ndi substrate;

3. Kuchuluka kochepa kwa okosijeni, ntchitoyo sidzasintha mtundu;

4. Sipadzakhala mabowo a mpweya kapena mabowo a mchenga mutagwiritsa ntchito welding;

5. Cholumikiziracho chikhoza kukonzedwa, makamaka choyenera kukonza nkhungu ndi zofunikira pakupukuta;

6. Chogwirira ntchitocho chimatha kufika pa 50~60 Rockwell kuuma pambuyo powotcherera.

Mapulogalamu:

Nkhungu, kupanga jakisoni molondola, kuyika zinthu mopanda chitsulo, kupondaponda, chitsulo chosapanga dzimbiri ndi zinthu zina zolimba monga ming'alu, kudula, kukonza makina opera ndi kutseka m'mphepete, kuwotcherera; kulondola kwambiri, m'mimba mwake wa malo owetcherera ndi laser ndi 0.2nm ~ 1.5nm yokha; malo otentha ndi ang'onoang'ono, kukonza. Chogwirira ntchito sichidzawonongeka; chitha kudulidwa pambuyo powotcherera popanda kukhudza zotsatira zake.

Makina owotcherera a laser opangidwa ndi kuwala

Chiyambi cha Chitsanzo:

Makina olumikizira laser olumikizira ulusi wa kuwala ndi mtundu wa zida zolumikizira laser zomwe zimagwirizanitsa kuwala kwa laser kwamphamvu kwambiri ndi ulusi wa kuwala, pambuyo polumikizira kutali, zimalumikiza kuwala kofanana kudzera pagalasi lozungulira, ndikuchita zolumikizira pa workpiece. Zimalumikiza nkhungu zazikulu ndi zigawo zolondola zomwe sizikupezeka, ndikuyika zolumikizira zosinthika zosakhudzana ndi kulumikiza, zomwe zimakhala ndi kusinthasintha kwakukulu. Kuwala kwa laser kumatha kugawa nthawi ndi mphamvu, ndipo kumatha kukonza matabwa angapo nthawi imodzi, zomwe zimapangitsa kuti zikhale zosavuta kuwotcherera.

Mbali yaikulu:

1. Makina owunikira kamera ya CCD omwe mungasankhe, oyenera kuyang'aniridwa komanso malo olondola;

2. Kugawa mphamvu kwa malo owetera ndi kofanana, ndipo kuli malo abwino kwambiri owala omwe amafunikira kuti zinthu zowetera zikhale bwino;

3. Sinthani ku ma weld osiyanasiyana ovuta, ma spot weld a zipangizo zosiyanasiyana, ndi ma weld a mbale zoonda mkati mwa 1mm;

4. Chipinda cholumikizira cha ceramic chomwe chatumizidwa chimagwiritsidwa ntchito, chomwe sichimakhudzidwa ndi dzimbiri, sichimatentha kwambiri, ndipo chimakhala ndi moyo wa zaka 8 mpaka 10), ndipo nthawi ya moyo wa nyale ya argon ndi yoposa 8 miliyoni; zida zapadera zodzipangira zokha ndi zida zitha kusinthidwa kuti zipange zinthu zambiri.

Mapulogalamu:

Amagwiritsidwa ntchito kwambiri popanga zipangizo zolumikizirana ndi kuwala, zida zamagetsi, makina azachipatala, mawotchi, magalasi, zinthu zolumikizirana ndi digito, zida zolondola, zida zamagetsi ndi mafakitale ena, komanso kukonza zolumikizira zazikulu za nkhungu, kuyika zinthu m'makina ndi kupangira jekeseni.

Nthawi yotumizira: Juni-02-2023