Kedu ka igwe ịgbado ọkụ laser si arụ ọrụ?

Igwe ịgbado ọkụ laser na-eji ike dị ukwuu nke pulse laser ahụ iji kpoo ihe a ga-ahazi n'ime obere oke, wee mechaa gbazee ya ka ọ bụrụ ọdọ mmiri a gbazere agbaze kpọmkwem, nke nwere ike ime ka ịgbado ọkụ dị nro, ịgbado ọkụ n'ubu, ịgbado ọkụ n'apata ụkwụ, ịgbado ọkụ n'apata ụkwụ, ịgbado ọkụ n'apata ụkwụ, wdg. Uru pụrụ iche ya na-emepe oghere ngwa ọhụrụ nke ịgbado ọkụ laser, na-enye ịgbado ọkụ nke ọma maka ihe ndị dị gịrịgịrị na obere akụkụ.

Kedu ihe eji eji igwe ịgbado ọkụ laser eme?

1. Ịgbado ọkụ

Isi ihe mere e ji eji igwe ịgbado ọkụ laser bụ ịgbado ọkụ. Ọ bụghị naanị na ọ nwere ike ịgbado ọkụ ihe ndị dị gịrịgịrị dịka efere ígwè anaghị agba nchara, efere aluminom, na efere galvanized, kamakwa enwere ike iji ya maka akụkụ ígwè ịgbado ọkụ, dịka ngwa kichin. Ọ dabara adaba maka arc dị larịị, kwụ ọtọ, na ịgbado ọkụ nke ụdị ọ bụla a na-ejikarị eme ihe n'igwe ziri ezi, ọla, ihe eletrọnịkị, batrị, elekere, nkwukọrịta, ọrụ aka na ụlọ ọrụ ndị ọzọ. Ọ nwere ike ịgbado ọkụ nke ọma n'ọtụtụ ebe dị mgbagwoju anya ma nwee arụmọrụ dị elu. Ma e jiri ya tụnyere ịgbado ọkụ argon arc ọdịnala na ịgbado ọkụ eletrik. Usoro ndị ọzọ nwere uru ndị ọzọ doro anya.

Site na iji igwe ịgbado ọkụ laser, eriri ịgbado ọkụ nwere obere obosara, nnukwu omimi, obere mpaghara ọkụ, obere mgbanwe, eriri ịgbado ọkụ dị nro ma mara mma, ogo ịgbado ọkụ dị elu, enweghị oghere ikuku, njikwa ziri ezi, mma ịgbado ọkụ kwụsiri ike, enweghị mkpa maka ọgwụgwọ ma ọ bụ ọgwụgwọ dị mfe mgbe ịgbado ọkụ gasịrị.

2. Ndozi

Ojiji nke igwe ịgbado ọkụ laser abụghị naanị ịgbado ọkụ, kamakwa ọ na-arụkwa ọrụ idozi mmebi, ntụpọ, ọkọ nke ebu ahụ, na oghere ájá, mgbawa, mgbanwe na ntụpọ ndị ọzọ nke ihe eji arụ ọrụ ígwè ahụ. Ebu ahụ ga-aka nká mgbe ejiri ya ogologo oge. Ọ bụrụ na a tụfuo ya ozugbo, mfu ahụ ga-adị ukwuu. Enwere ike iji ebu ahụ nke nwere nsogbu ọzọ mee ihe ọzọ site n'ịrụzi ebu ahụ nwere nsogbu site na igwe ịgbado ọkụ laser, karịsịa mgbe a na-arụzi elu dị mma, na-ezere nsogbu abụọ nke nrụgide okpomọkụ na ọgwụgwọ mgbe ịgbado ọkụ gasịrị. Otu usoro, na-azọpụta oge mmepụta na ọnụ ahịa mmepụta nke ukwuu.

Kedu usoro ịgbado ọkụ nke igwe ịgbado ọkụ laser nwere?

1. Ịgbado ọkụ n'etiti iberibe

Gụnyere ịgbado ọkụ n'ubu, ịgbado ọkụ n'akụkụ, ịgbado ọkụ n'etiti oghere, na ịgbado ọkụ n'etiti oghere.

2. Njikọ waya na waya

Gụnyere ịgbado ọkụ n'azụ waya, ịgbado ọkụ n'ofe, ịgbado ọkụ n'akụkụ, na ịgbado ọkụ n'ụdị T.

3. Ịgbado waya ígwè na ihe ndị mejupụtara blọk

Ịgbado ọkụ laser nwere ike ime ka njikọ waya ígwè na ihe ndị mejupụtara blọk ahụ dị mfe, nha nke ihe ndị mejupụtara blọk ahụ nwekwara ike ịbụ nke a na-anaghị agbaso. E kwesịrị ilebara anya na akụkụ geometric nke ihe ndị mejupụtara eriri ahụ n'oge ịgbado ọkụ.

4. Ịgbado ọkụ nke ọla dị iche iche

Ịgbado ụdị ígwè dị iche iche na-edozi oke paramita ịgbado ọkụ na ịgbado ọkụ. Ọ ga-ekwe omume ịgbado ọkụ laser n'etiti ihe dị iche iche naanị site na iji ụfọdụ ihe.

Kedu otu esi ahọrọ isi iyi laser kwesịrị ekwesị?

Isi iyi laser Yg:

Mpempe akwụkwọ ígwè, njikọ ọla edo, ihe ndị na-eme mkpọtụ titanium, agụba agụba maka ịgbado ọkụ na laser pulsed.

Ụdị laser a na-egbochi ígwè ahụ ịgbaze ma ọ bụ gbanwee.

Maka ọla dị gịrịgịrị na nke dị mfe.

Isi iyi laser CW:

Nke a dị oke ọnụ ma e jiri ya tụnyere laser pulsed. Ọ na-ebelatakwa ọnụ ahịa ọrụ.

Ihe kachasị dị irè na ọla ndị na-adịghị ike.

Akwadoro maka ịgbado akụkụ dị oke arọ.

Ọ nwere ike ibute nsogbu ma ọ bụrụ na ejiri ya na ígwè ma ọ bụ akụkụ ndị dị gịrịgịrị. N'ọnọdụ a, laser nwere ike imebi, gbazee ma ọ bụ mebie akụkụ ahụ.

Kedu ụdị igwe ịgbado ọkụ dị na mkpokọta?

A makwaara igwe ịgbado ọkụ laser dịka igwe ịgbado ọkụ laser na igwe ịgbado ọkụ laser. Nkewa ndị a kapịrị ọnụ bụ ndị a:

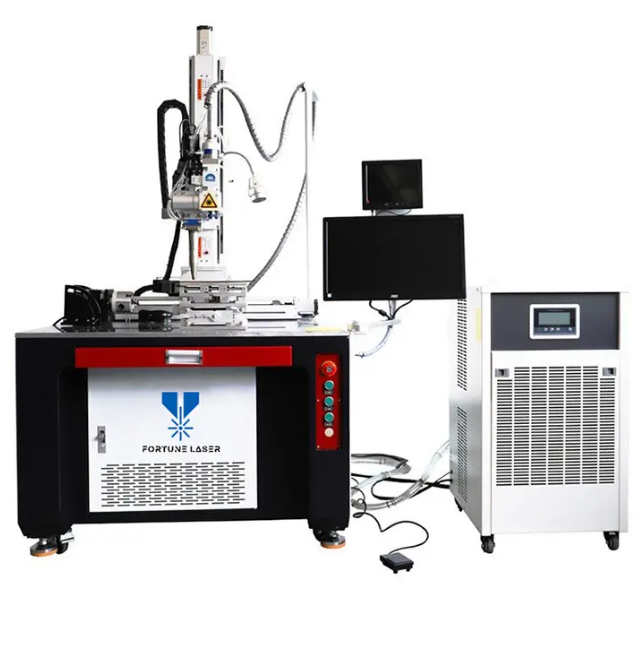

1. Igwe ịgbado ọkụ laser aka:

Nke a bụ ụdị ngwa ịgbado ọkụ kachasị ewu ewu n'ahịa. A na-ejikarị ya agbado ọkụ dị iche iche.

2. Igwe ịgbado ọkụ laser ntụpọ:

Enwere ike iji ya maka ọla edo na ọlaọcha, ihe e ji ekpuchi oghere nke ihe eletrọnịkị, ihe e ji ekpuchi ntụpọ, ihe e ji emechi njikọta, wdg.

3. Igwe ịgbado ọkụ laser akpaka:

Ọ dabara adaba maka ịgbado ọkụ akpaka nke ahịrị kwụ ọtọ na okirikiri nke ihe eji arụ ọrụ ígwè, a na-ejikarị ya eme ihe n'ụlọ ọrụ dịka batrị ekwentị mkpanaaka, ọla, ihe eletrọnịkị, ihe mmetụta, elekere na elekere, igwe nkenke, nkwukọrịta, na aka aka.

4. Igwe ịgbado ọkụ laser:

A na-ejikarị ya arụzi ebu n'ụlọ ọrụ mmepụta na ịkpụzi ebu dịka ekwentị mkpanaaka, ngwaahịa dijitalụ, ụgbọala na ọgba tum tum, a na-ejikwa ya eme ihe maka ịgbado ọkụ aka.

5. Igwe ịgbado ọkụ laser nke eriri anya:

Maka akụkụ ndị siri ike ịnweta maka ịgbado ọkụ, a na-etinye njikọta nnyefe na-agbanwe agbanwe nke na-anaghị emetụ aka, nke nwere ike ịgbanwe agbanwe karịa. Osisi laser ahụ nwere ike ịmepụta nkewa oge na ike, ma nwee ike ịhazi ọtụtụ ogwe n'otu oge, nke na-enye ọnọdụ maka ịgbado ọkụ nke ọma.

6. Igwe ịgbado ọkụ laser nke eriri anya galvanometer:

Ngwakọta zuru oke nke sistemụ ngagharị galvanometer na sistemụ ịgbado ọkụ laser. Chekwaa oge ịtọgbọ chakoo n'oge ịgbado ọkụ otu ebe, ma melite arụmọrụ site na ugboro 3-5 ma e jiri ya tụnyere oche ọrụ eletriki ọdịnala.

Okwu Mmalite nke ụdị igwe ịgbado ọkụ ụfọdụ:

Igwe ịgbado ọkụ laser aka

Ngwa nhazi ígwè laser kachasị ewu ewu n'ahịa bụ igwe ịgbado ọkụ laser aka. N'ime ngwa ịgbado ọkụ ọdịnala, njikọta nke ahụmịhe ịgbado ọkụ bara ụba na teknụzụ dị mkpa iji mezuo mmepụta kwa ụbọchị, ọsọ ya na-aga nwayọ, ọdịdị nke ịgbado ọkụ chọrọ ka amịchaa ya mgbe e mesịrị. Nhazi na-ewe oge ma na-agwụ ike.

Okwu mmeghe nke ụdị nlereanya: Jiri eriri anya mee ka laser na-ebufe, ma lekwasị anya na oghere laser ahụ kpọmkwem na akụkụ ịgbado ọkụ site na egbe ịgbado ọkụ nke ejiri aka jide. O nwere njirimara nke oke nkenke, arụmọrụ dị elu na mpaghara okpomọkụ na-emetụta obere, ọ dịkwa mma maka ịgbado ọkụ obere, akụkụ siri ike ma ọ bụ akụkụ siri ike iru.

Isi uru:

1 Ọrụ a dị mfe, ọ dịghị mkpa ahụmịhe teknụzụ ịgbado ọkụ ọkachamara, a pụkwara ịmalite ọrụ ahụ mgbe awa abụọ nke ọzụzụ dị mfe gasịrị.

2 Ọsọ ịgbado ọkụ dị oke ọsọ, ihe mgbado ọkụ laser nwere ike dochie mmepụta nke ihe mgbado ọkụ nkịtị 3 ruo 5.

3 Ịkwado ọkụ nwere ike ịbụ ihe na-enweghị ihe oriri ọ bụla, na-eme ka ọ ghara ịdị ọnụ ala n'ihe a na-emepụta.

4 Mgbe e mechara ịgbado ọkụ ahụ, ihe e ji ejikọta ihe na-egbuke egbuke na-acha ọcha ma dịkwa ọcha, a pụkwara ime ya n'enweghị ịcha ya.

5. Ike nke igwe ịgbado ọkụ laser dị n'ime ya, oke ntụgharị okpomọkụ dị obere, ngwaahịa ahụ adịghịkwa mfe ịgbanwe.

6 Ike nke igwe ịgbado ọkụ laser dị elu, ike ịgbado ọkụ dịkwa elu nke ukwuu.

7. Ike na ike nke igwe ịgbado ọkụ laser na-achịkwa site na dijitalụ, nke nwere ike imezu ihe dị iche iche achọrọ maka ịgbado ọkụ, dịka ịbanye n'ime zuru oke, ịbanye n'ime, ịgbado ọkụ n'ebe a na-adọba ụgbọala na ihe ndị ọzọ.

Ihe ndị dị mkpa na ngwa ụlọ ọrụ: a na-ejikarị ya eme ihe na ihe eletrọnịkị, akụkụ ụgbọala, ngwa ọrụ, igwe nkenke, ngwa nkwukọrịta na ụlọ ọrụ ndị ọzọ, ígwè anaghị agba nchara, ígwè carbon, ígwè silicon, alloy aluminum, titanium alloy, mpempe akwụkwọ galvanized, mpempe akwụkwọ galvanized, ọla kọpa, wdg. Ngwakọta ngwa ngwa nke ihe dị iche iche na ịgbado ọkụ n'etiti ihe dị iche iche.

Igwe ịgbado ọkụ laser akpaka-igwe ịgbado ọkụ laser akpaka abụọ

Okwu Mmalite nke Ụdị:

Igwe a na-eji oghere seramiiki abụọ nke e si UK bịa, nke nwere ike dị ike, ike mmemme na njikwa sistemụ nwere ọgụgụ isi. Axis Z nke ebe ọrụ nwere ike ịkwaga elu na ala site na eletriki iji lekwasị anya, PC ụlọ ọrụ mmepụta ihe na-achịkwa ya. Ejiri tebụl X/Y dị iche iche nke nwere akụkụ atọ na-agagharị agagharị. Ihe mgbakwunye ọzọ a na-agbanwe agbanwe (80mm ma ọ bụ p 125mm nhọrọ) iji nweta njikọta laser akpaka abụọ. Sistemụ nlekota ahụ na-eji microscope, ọkụ uhie na CCD. Ejiri sistemụ mmiri oyi dị n'èzí mee ya.

Isi uru:

1. A na-eji oghere seramiiki nke nwere ọkụ abụọ e si UK bịa, nke na-eguzogide nchara ma na-eguzogide okpomọkụ dị elu, ndụ oghere ahụ dịkwa afọ 8-10.

2. Mmepụta arụmọrụ dị elu, ọsọ ịgbado ọkụ dị ngwa ngwa, a pụkwara imezu mmepụta oke akpaka nke ahịrị mgbakọ ahụ.

3. Isi laser nwere ike ịtụgharị 360°, a pụkwara ibugharị ụzọ anya niile 360° ma gbasaa azụ na azụ.

4. Enwere ike ịgbanwe nha nke ebe ọkụ ahụ site na iji ọkụ eletrik.

5. Enwere ike ibugharị ikpo okwu ọrụ ahụ site na iji eletriki n'akụkụ atọ.

Ihe ndị dị mkpa na ngwa ụlọ ọrụ:

Ọ dabara adaba maka ketulu, iko vacuum, efere ígwè anaghị agba nchara, sensọ, waya tungsten, diode ike dị elu (transistors), alloy aluminom, casing laptọọpụ, batrị ekwentị mkpanaaka, aka ọnụ ụzọ, ebu, ngwa eletriki, nzacha, nozzles, ngwaahịa igwe anaghị agba nchara, golf Isi bọọlụ, ihe eji arụ ọrụ zinc na ịgbado ọkụ ndị ọzọ. Eserese ndị a na-agbado ọkụ gụnyere: isi ihe, ahịrị kwụ ọtọ, okirikiri, square ma ọ bụ eserese ụgbọelu ọ bụla nke ngwanrọ AutoCAD sere.

Njikọta na Desktọpụ, nkewa, obere ịgbado ọkụ laser

Okwu Mmalite nke Ụdị:

A na-ejikarị igwe ịgbado ọkụ laser eme ihe maka ịrụzi oghere na ntụpọ ịgbado ọkụ nke ọla edo na ọlaọcha. Ịgbado ọkụ laser bụ otu n'ime akụkụ dị mkpa nke iji teknụzụ nhazi ihe laser eme ihe. Usoro ịgbado ọkụ ahụ bụ ụdị nnyefe okpomọkụ, ya bụ, radieshon laser na-ekpo elu nke ihe eji arụ ọrụ ahụ ọkụ, okpomọkụ elu ya na-agbasakwa n'ime ime site na nnyefe okpomọkụ. Site n'ịchịkwa obosara, ike, ike kachasị elu na ugboro ugboro nke laser pulse Parameters dị ka ugboro ugboro na-eme ka ihe eji arụ ọrụ ahụ gbazee ma mepụta ọdọ mmiri a gbazere agbaze. N'ihi uru pụrụ iche ya, etinyere ya nke ọma na nhazi na ịgbado ọkụ ọla edo na ọlaọcha nke obere akụkụ.

Atụmatụ nlereanya:

Ọsọ ọsọ ọsọ, arụmọrụ dị elu, omimi buru ibu, obere mgbanwe, obere mpaghara okpomọkụ metụtara, mma ịgbado ọkụ dị elu, enweghị mmetọ nke njikọ solder, arụmọrụ dị elu na nchekwa gburugburu ebe obibi.

Isi uru:

1. Enwere ike ịgbanwe ike, obosara obi, ugboro ole, nha ntụpọ, wdg n'ime oke dị iche iche iji nweta ọtụtụ mmetụta njikọta. A na-achịkwa ma na-agbanwe paramita ndị a n'ime oghere mechiri emechi, nke dị mfe ma dị irè.

2. A na-eji oghere seramiiki e si mba United Kingdom weta, nke na-eguzogide nchara, na-eguzogide okpomọkụ dị elu, ma nwee arụmọrụ mgbanwe fotoelectric dị elu.

3. Nabata usoro ndo anya kachasị elu n'ụwa, nke na-ewepụ mkpasu iwe n'anya n'oge ọrụ.

4. O nwere ike ịrụ ọrụ mgbe niile ruo awa iri abụọ na anọ, igwe ahụ dum nwere arụmọrụ ọrụ kwụsiri ike, ọ naghịkwa arụzi ya n'ime awa iri.

5. Nhazi mmadụ, nke kwekọrọ na ergonomics, nwere ike ịrụ ọrụ ogologo oge na-enweghị ike ọgwụgwụ.

Igwe ịgbado ọkụ laser

Okwu Mmalite nke Ụdị:

Igwe ịgbado ọkụ laser bụ ụdị pụrụ iche emere maka ụlọ ọrụ ebu. A na-eji igwe a eme ihe pụrụ iche iji dochie igwe ịgbado ọkụ argon arc ọdịnala maka ịrụzi ebu ziri ezi. Ihe ndị dị mkpa nke igwe ahụ bụ ngwaahịa niile e si mba ọzọ bịa. Ngwanrọ ahụ na-eji ngosipụta kristal mmiri mmiri buru ibu, njikọ ahụ dịkwa mfe ma doo anya, onye na-arụ ọrụ ahụ dịkwa mfe ịmụta na iji. Enwere ike ịhazi ụdị ọrụ dị iche iche echekwara n'onwe gị, enwere ike itinye ọrụ ebe nchekwa na-adịgide adịgide na ihe dị iche iche.

Atụmatụ nlereanya:

1. Ebe okpomọkụ metụtara dị obere ma agaghị akpata mgbanwe nke ebu ziri ezi;

2. Omimi nke ịgbado ọkụ ahụ buru ibu, ịgbado ọkụ ahụ siri ike. Agbazere kpamkpam, ọ dịghịkwa ihe ọ bụla a ga-arụzi. Enweghị ntụpọ n'etiti akụkụ e buliri elu nke ọdọ mmiri ahụ na ihe e ji kpuchie ya;

3. Ọkwa oxidation dị ala, ihe eji arụ ọrụ agaghị agbanwe agba;

4. Agaghị enwe oghere ikuku ma ọ bụ oghere ájá mgbe ejiri ihe mgbado ọkụ rụọ ọrụ;

5. Enwere ike ịhazi ihe e ji agwakọta ihe, nke kachasị mma maka ndozi ebu yana ihe achọrọ maka ịchacha ihe;

6. Ihe e ji arụ ọrụ ahụ nwere ike iru ike Rockwell ruru 50 ~ 60 mgbe ọ gbanyere ya.

Ngwa:

Ebu, ịkpụzi ihe ntụtụ nke ọma, ịkpụ ihe n'ime ihe, ịcha stampụ, ígwè anaghị agba nchara na ihe ndị ọzọ siri ike dịka mgbawa, ịkpụcha ihe, iyi igwe ngwepịa ọnụ na ịrụzi akụkụ mkpuchi, ịgbado ọkụ; izi ezi dị elu, dayameta ebe ịgbado ọkụ laser dị naanị 0.2nm ~ 1.5nm; ebe a na-ekpo ọkụ dị obere, nhazi. Agaghị agbanwe ihe eji arụ ọrụ ahụ; enwere ike ịcha ya mgbe ịgbado ọkụ gasịrị na-enweghị mmetụta ọ bụla.

Ngwa anya eriri nnyefe akpaka laser ịgbado ọkụ igwe

Okwu Mmalite nke Ụdị:

Igwe ịgbado ọkụ laser nke eriri anya bụ ụdị ngwa ịgbado ọkụ laser nke na-ejikọ oghere laser dị elu na eriri anya, mgbe nnyefe dị anya gasịrị, na-ejikọta ìhè yiri ya site na enyo na-agbakọta, ma na-arụ ọrụ ịgbado ọkụ na workpiece. Na-agbado ebu buru ibu na akụkụ ziri ezi na-enweghị ike iru, ma na-etinye njikọta nnyefe na-agbanwe agbanwe na-enweghị kọntaktị, nke nwere mgbanwe ka ukwuu. Ogwe laser ahụ nwere ike nweta nkewa oge na ike, ma nwee ike ịhazi ọtụtụ ogwe n'otu oge, na-enye ọnọdụ dị mma maka ịgbado ọkụ.

Isi ihe dị mkpa:

1. Sistemụ nlekota igwefoto CCD nhọrọ, dị mma maka nlele na nhazi ziri ezi;

2. Ike nkesa nke ebe ịgbado ọkụ bụ otu, o nwekwara ebe ìhè kacha mma achọrọ maka njirimara ịgbado ọkụ;

3. Mee ka ọ dabara na njikọta dị iche iche dị mgbagwoju anya, njikọta ntụpọ nke ngwaọrụ dị iche iche, na njikọta nke efere dị gịrịgịrị n'ime 1mm;

4. A na-eji oghere seramiiki e si mba ọzọ abata, nke na-eguzogide nchara, na-eguzogide okpomọkụ dị elu, ndụ oghere ahụ dịkwa afọ 8 ruo 10), ndụ oriọna argon karịrị nde 8; enwere ike ịhazi ngwaọrụ na ihe ndozi akpaka pụrụ iche iji mepụta ngwaahịa dị iche iche.

Ngwa:

A na-ejikarị ya eme ihe n'ọtụtụ ebe n'ịmepụta ngwa nkwukọrịta anya, ihe eletrọnịkị, igwe ahụike, elekere, iko, ngwaahịa nkwukọrịta dijitalụ, akụkụ nkenke, ngwaike na ụlọ ọrụ ndị ọzọ, yana ịrụzi nnukwu ihe eji ebu ebu, ihe eji egbutu ihe na ihe eji etinye ihe n'ime ya.

Oge ozi: Jun-02-2023