Kev vam meej ntawm ib qho hlau nroglaser vuamnyob ntawm nws cov khoom tseem ceeb ntawm lub cev. Piv txwv li, qhov kev cuam tshuam siab tuaj yeem cuam tshuam lub zog ntawm lub laser, thaum qhov kev coj ua thermal siab ua rau lub cua sov ploj mus sai sai ntawm thaj chaw vuam. Cov yam ntxwv no, nrog rau qhov chaw yaj, txiav txim siab seb cov khoom siv nqus tau lub zog zoo li cas los tsim kom muaj qhov vuam zoo thiab meej.

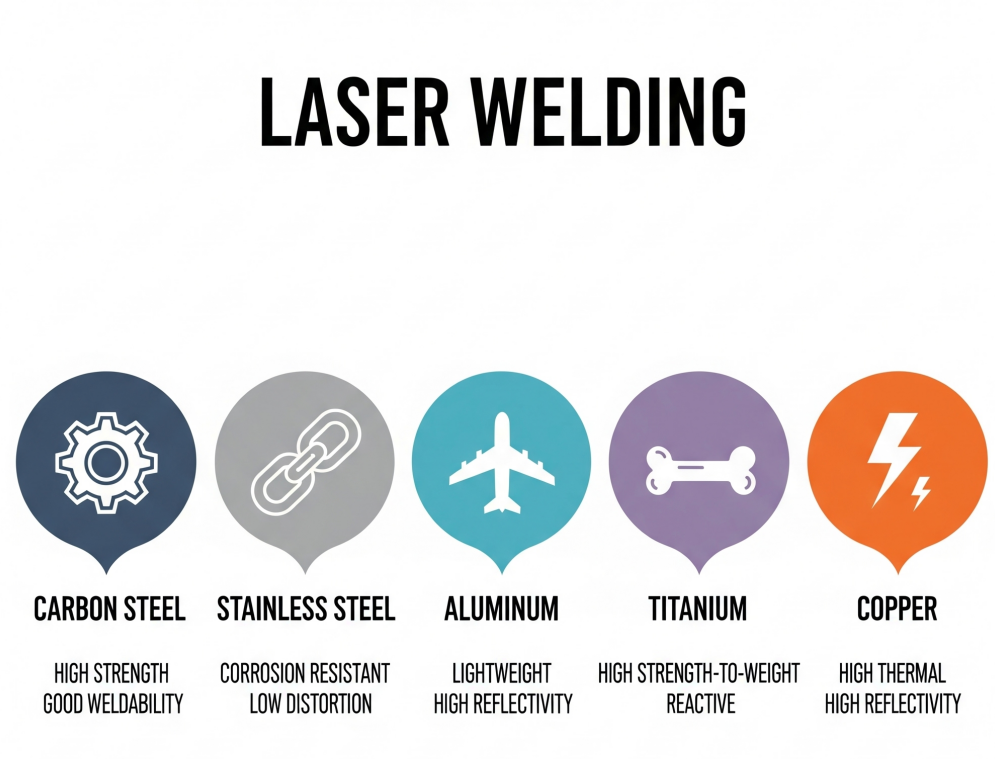

Nov yog kev rhuav tshem ntawm cov hlau uas siv ntau thiab lawv cov khoom siv li cas.

Laser Vuam Cov Hlau Carbon

Cov hlau carbon yog cov hlau sib xyaw ua ke uas muaj cov pa roj carbon txog li 2.1%. Cov pa roj carbon yog qhov tseem ceeb ntawm nws cov khoom.

Cov hlau uas tsis muaj carbon ntau(tsawg dua 0.25% carbon) yog ductile, tawv, thiab yooj yim machining thiab weldable. Nws feem ntau siv rau lub cev vaj huam sib luag, hlau, thiab yeeb nkab.

Hlau nruab nrab-carbon(0.25% txog 0.60% carbon) muaj zog dua thiab tawv dua li cov hlau uas muaj carbon tsawg. Qhov no ua rau nws tsim nyog rau cov khoom uas xav tau lub zog ntau dua thiab tiv taus kev hnav, xws li cov iav, cov ncej, thiab cov log tsheb ciav hlau.

Cov hlau carbon ntau(ntau tshaj 0.60% carbon) yog qhov muaj zog tshaj plaws thiab nyuaj tshaj plaws ntawm peb yam, tab sis nws kuj yog qhov tsis yooj yim tshaj plaws thiab tawg yooj yim tshaj plaws. Nws qhov nyuaj ua rau nws zoo tagnrho rau cov cuab yeej txiav, cov caij nplooj ntoos hlav, thiab cov xov hlau muaj zog siab, tab sis nws yuav tsum tau ua tib zoo tuav thaum lub sijhawm vuam kom tiv thaiv kev tawg.

Cov hlau carbon yog ib qho khoom siv ua haujlwm hauv kev tsim khoom, thiab nws yuav siv laser vuam zoo nkauj.

Cov txiaj ntsigKoj tau txais cov vuam zoo, tob nrog kev ua haujlwm raug zoo heev thiab me ntsis kev cuam tshuam. Qhov ceev yog qhov zoo heev, ua rau muaj kev tsim khoom ntau ntxiv hauv pem teb Hoobkas.

Cov Kev Xav TxogQhov txias sai ntawm cov txheej txheem laser tuaj yeem ua rau qhov vuam tawg thiab yooj yim tawg. Qee zaum, kev ua kom sov ua ntej yog qhov tsim nyog los qeeb qhov txias thiab tiv thaiv teeb meem.

Laser Vuam Stainless Hlau

Qhov no yog qhov sib phim ua tau saum ntuj ceeb tsheej. Kev vuam laser yog cov txheej txheem zoo tshaj plaws rau cov hlau tsis xeb, tshwj xeeb tshaj yog rau cov lag luam uas xav tau kev huv.

Cov txiaj ntsigQhov kub uas nkag mus rau hauv cov hlau tsis xeb yog qhov yeej loj heev. Nws khaws cov khoom tiv taus xeb ntawm cov hlau tsis xeb los ntawm kev tiv thaiv ib yam dab tsi hu ua "carbide precipitation." Qhov no ua rau cov vuam huv si thiab raug phais, yog vim li cas nws thiaj li nrov heev hauv kev lag luam kho mob thiab zaub mov.

Cov Kev Xav TxogFeem ntau cov hlau tsis xeb uas siv ntau, xws li 300 series (piv txwv li, 304, 316), vuam tau zoo heev. Txawm li cas los xij, qee qib lwm yam, xws li 400 series, tuaj yeem tawg yooj yim hauv thaj chaw uas raug cua sov.

Laser Vuam Aluminium

Kev vuam txhuas yeej ib txwm nyuaj, tab sis kev vuam laser hloov pauv qhov kev ua si.

Cov txiaj ntsig: Txhuas yog ib qho khoom siv hluav taws xob zoo heev, uas txhais tau tias nrog kev vuam ib txwm muaj, qhov kub kis mus rau sab nraud thiab ua rau tag nrho cov khoom tawg. Lub zog laser tsom mus rau lub zog thiab qhov cua sov qis daws qhov teeb meem no, txo qhov kev cuam tshuam.

Cov Kev Xav Txog: Aluminium muaj zog heev. Qhov chaw ci ntsa iab tuaj yeem ua rau lub teeb laser tawm mus. Kev ua tiav nyob ntawm ob peb yam tseem ceeb: kev ntxuav qhov chaw kom huv si, cov roj tiv thaiv zoo, thiab siv hom laser zoo (feem ntau yog cov fiber lasers) kom ntseeg tau tias lub zog raug nqus.

Laser Vuam Titanium

Yog tias koj xav tau vuam titanium, laser yog ib qho ntawm koj cov cuab yeej zoo tshaj plaws rau txoj haujlwm.

Cov txiaj ntsigTitanium yog ib hom hlau uas ua rau muaj kev sib kis tau yooj yim los ntawm cov pa oxygen hauv huab cua thaum nws yaj, ua rau qhov vuam tsis muaj zog thiab tawg yooj yim. Qhov ceev thiab qhov tseeb ntawm lub laser txo lub sijhawm uas cov hlau yaj thiab raug, txo qhov kev pheej hmoo ntawm kev sib kis thiab kev tawg yooj yim.

Cov Kev Xav TxogIb yam li TIG vuam titanium, koj tseem yuav tsum ceev faj heev. Kev huv si thiab kev tiv thaiv zoo meej nrog cov roj inert (xws li argon) tsis tuaj yeem sib tham tau.

Laser Vuam Tooj Liab thiab Lwm Cov Hlau Uas Muaj Kev Cuam Tshuam

Qhov no yog qhov uas laser welding thawb cov ciam teb ntawm qhov ua tau.

Cov txiaj ntsigLub tshuab vuam laser tuaj yeem koom nrog cov khoom siv uas muaj kev cuam tshuam zoo li tooj liab, uas nyuaj heev rau vuam nrog yuav luag txhua txoj kev. Qhov no tseem ceeb rau cov ntawv thov xws li roj teeb tsheb fais fab (EV), qhov twg tooj liab thiab txhuas yuav tsum koom ua ke.

Cov Kev Xav TxogQhov no yog cov khoom siv theem kws tshaj lij. Qhov kev cuam tshuam siab thiab kev ua kom sov tau zoo tuaj yeem ua rau lub laser lub optics puas tsuaj yog tias tsis tswj hwm kom raug. Nws feem ntau xav tau cov khoom siv tshwj xeeb, nrog rau cov txheej txheem siab heev.

Cov L yog dab tsikev ua piv txwv ntawm Laser Welding?

Txawm hais tias nws zoo li yog ib qho cuab yeej txuj ci tseem ceeb los xij, nws tsis zoo tag nrho rau txhua txoj haujlwm. Nws yog ib qho tseem ceeb kom nkag siab txog kev sib pauv.

1.Tus nqi pib siabLub tshuab vuam laser tshaj lij yog kev nqis peev tseem ceeb, kim dua li cov qauv MIG lossis TIG ib txwm muaj.

2.Cov Kev Cai Sib Koom Tes NrujRaws li tau hais lawm, cov lasers xav tau qhov haum zoo kawg nkaus. Yog tias koj cov khoom muaj qhov sib txawv lossis tsis txiav kom meej, lub laser yuav tsis tuaj yeem txuas lawv kom zoo.

3.Cov Teeb Meem Kev Xav TauCov ntaub ntawv ci ntsa iab xws li txhuas thiab tooj liab tuaj yeem nyuaj rau vuam yam tsis muaj lasers thiab cov txheej txheem tshwj xeeb.

4.Kev Txhawj Xeeb Txog Kev Nyab XeebLub teeb laser muaj zog heev ua rau muaj kev phom sij heev thiab ua rau raug mob qhov muag thiab kub hnyiab ntawm daim tawv nqaij, txawm tias los ntawm kev cuam tshuam los xij. Yuav tsum muaj cov thawv tiv thaiv kev nyab xeeb thiab cov khoom siv tiv thaiv tus kheej (PPE) kom zoo.

Cov Kev Xyaum Zoo Tshaj Plaws rau Flawless Laser Welds

Yuav kom tau txais txiaj ntsig zoo tshaj plaws ntawm koj cov txheej txheem laser welding, koj yuav tsum ua tib zoo saib xyuas cov hauv paus ntsiab lus.

Kev npaj yog txhua yam

Kev Sib Koom TesPeb hais tsis tau txaus: koj cov khoom yuav tsum sib haum ua ke zoo. Sim kom muaj qhov sib txawv tsawg dua 10% ntawm qhov tuab ntawm cov khoom kom tau qhov zoo tshaj plaws.

Kev Ntxuav Qhov ChawTshem tawm txhua yam uas tsis yog hlau. Qhov no txhais tau tias tshem tawm tag nrho cov roj, roj, oxides, thiab lwm yam khoom tsis huv. Ib qho chaw huv si yog qhov tseem ceeb kom tiv thaiv cov qhov thiab lwm yam tsis zoo hauv koj qhov vuam.

Tswj Koj Cov Txheej Txheem

Cov roj tiv thaivIb yam li TIG thiab MIG, kev vuam laser siv cov roj inert (feem ntau yog argon lossis helium) los tiv thaiv lub pas dej vuam uas yaj los ntawm cov pa oxygen thiab nitrogen hauv huab cua, ua kom muaj kev vuam zoo thiab huv.

Kev Txhim Kho Cov Txheej TxheemKoj yuav tsum tau teeb tsa koj cov chaw. Lub zog laser, qhov ceev ntawm kev vuam, thiab qhov deb ntawm qhov tsom mus rau yuav tsum tau teeb tsa kom zoo rau cov khoom siv thiab qhov tuab uas koj ua haujlwm nrog.

Kev Nyab Xeeb Ua Ntej, Txhua Lub Sijhawm

Kev vuam laser tsis yog ib qho txheej txheem uas koj tuaj yeem ua siab deb txog. Lub teeb uas tsom mus rau qhov chaw muaj zog heev. Txhua tus neeg uas nyob ze ntawm qhov kev ua haujlwm yuav tsum hnav cov tsom iav tshwj xeeb rau kev nyab xeeb laser uas ntsuas rau qhov ntev ntawm koj lub laser.

Puas yog lub tshuab laser welding yog qhov kev xaiv zoo rau koj?

Yog li, koj puas yuav tsum nqis peev rau hauv laser welding?

Cia peb rov hais dua. Kev vuam laser yog ib qho cuab yeej tsim khoom siab heev uas muab kev ceev, kev raug, thiab qhov zoo tsis sib xws. Qhov sib pauv yog tus nqi pib siab thiab cov kev cai nruj rau cov khoom huv si, haum zoo.

Peb qhov kev xav kawgYog tias koj txoj haujlwm xav tau ntau yam khoom, kev siv tshuab ua haujlwm, thiab kev ua kom raug—tshwj xeeb tshaj yog rau cov ntaub ntawv uas yooj yim los yog nyuaj—ces kev vuam laser tsis yog lwm txoj kev xaiv xwb. Nws yog qhov kev daws teeb meem zoo tshaj plaws uas tuaj yeem hloov pauv koj cov khoom tsim tawm.

Lub sijhawm tshaj tawm: Lub Yim Hli-15-2025