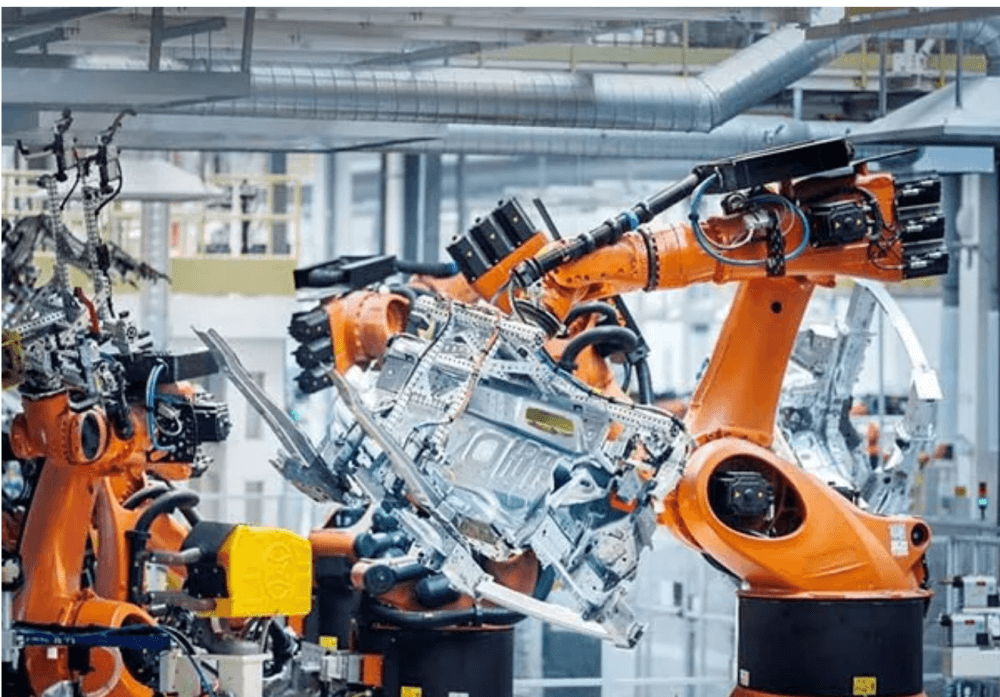

Cov neeg hlau vuam lasertau hloov pauv txoj kev vuam los ntawm kev qhia txog cov yam ntxwv siab heev uas ua rau kev ua haujlwm zoo dua thiab kev tsim khoom ntau dua. Cov neeg hlau no muaj ntau yam haujlwm uas ua rau cov txheej txheem vuam yooj yim dua, ua kom raug dua thiab xyuas kom muaj kev nyab xeeb siab tshaj plaws. Tsab xov xwm no tsom mus rau kev nkag mus rau hauv lub peev xwm ntawm cov neeg hlau vuam laser, hais txog lawv lub luag haujlwm hauv kev ua kom kev vuam zoo dua thiab ua tiav kev ua haujlwm tsis siv neeg. Peb tseem yuav tshawb nrhiav ntau yam khoom piav qhia xws li kev ua haujlwm viav vias, kev tiv thaiv tus kheej, kev ua haujlwm vuam, kev ua haujlwm tiv thaiv kev sib tsoo, kev ua haujlwm nrhiav qhov txhaum, kev sib cuag hlau nplaum, arc tawg rov pib dua.

1. Kev ua haujlwm ntawm kev viav vias:

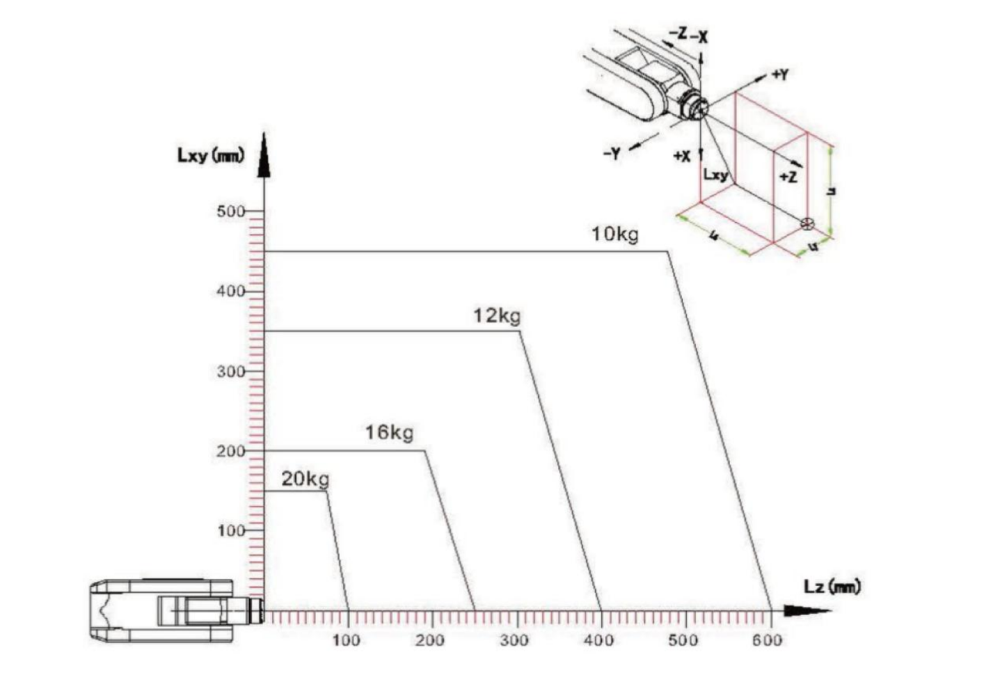

Ib qho ntawm cov yam ntxwv tseem ceeb ntawm ib qholaser vuam neeg hlauyog nws lub luag haujlwm oscillating. Qhov feature no tso cai rau lub neeg hlau txav mus los hauv kev txav oscillating, npog thaj chaw loj dua li cov txheej txheem vuam ib txwm muaj. Qhov oscillating feature ua kom ntseeg tau tias lub teeb laser npog thaj chaw dav dua, txo lub sijhawm vuam uas xav tau rau cov haujlwm loj dua. Los ntawm kev ua kom thaj chaw npog ntau tshaj plaws, qhov swing feature pab ua kom muaj kev tsim khoom ntau dua thiab ua haujlwm tau zoo hauv kev siv vuam.

2. Kev tiv thaiv tus kheej:

Cov neeg hlau laser vuam tau nruab nrog cov yam ntxwv tiv thaiv tus kheej kom ntseeg tau tias lawv lub neej ntev thiab tiv thaiv kev puas tsuaj. Qhov no ua haujlwm ua ib qho kev tiv thaiv tiv thaiv cov xwm txheej tsis zoo xws li overheating, voltage deviations lossis lub zog hloov pauv. Cov yam ntxwv tiv thaiv tus kheej ntawm tus neeg hlau tsis yog tsuas yog tiv thaiv nws cov khoom sab hauv, tab sis kuj tiv thaiv kev puas tsuaj sab nraud los ntawm cov hluav taws xob vuam lossis cov khib nyiab. Los ntawm kev tswj nws qhov kev ncaj ncees, tus neeg hlau tuaj yeem xa cov txiaj ntsig vuam zoo thiab ntev nws lub neej.

3. Kev ua haujlwm ntawm kev vuam:

Kev muaj peev xwm ntawm kev sib txuas lus yog ib feem tseem ceeb ntawmcov neeg hlau laser vuam, ua rau lawv nrhiav tau thiab teb rau cov kev hloov pauv hauv qhov chaw vuam. Qhov feature no siv cov sensors siab heev los ntsuas qhov tseeb xws li cov hlau tuab, kev sib koom ua ke thiab qhov kub thiab txias. Los ntawm kev hloov kho rau cov kev hloov pauv no hauv lub sijhawm tiag tiag, tus neeg hlau vuam ua kom ntseeg tau tias vuam raws txoj kev xav tau, ua rau muaj qhov zoo tshaj plaws ntawm kev vuam thiab txo qhov xav tau kev hloov kho tes.

4. Kev ua haujlwm tiv thaiv kev sib tsoo:

Kev nyab xeeb yog qhov tseem ceeb tshaj plaws hauv txhua qhov chaw ua haujlwm, thiabcov neeg hlau laser vuammuaj cov yam ntxwv tiv thaiv kev sib tsoo kom tiv thaiv kev sib tsoo kom tsis txhob ua rau muaj xwm txheej lossis kev puas tsuaj. Qhov no siv kev sib xyaw ua ke ntawm cov sensors, koob yees duab, thiab software algorithms los ntes cov teeb meem hauv txoj kev ntawm tus neeg hlau. Thaum pom tau, tus neeg hlau yuav hloov kho nws txoj kev kom tsis txhob muaj kev sib tsoo. Qhov no tsis yog tsuas yog tiv thaiv tus neeg hlau ntawm kev puas tsuaj xwb, tab sis kuj ua kom muaj kev nyab xeeb ntawm cov neeg ua haujlwm thiab cov khoom siv nyob ze, tshem tawm qhov kev pheej hmoo ntawm kev sib tsoo thiab kev kho kim heev.

5. Kev ua haujlwm nrhiav kom pom qhov txhaum:

Yuav kom paub tseeb tias kev vuam txuas ntxiv mus thiab tsis muaj kev cuam tshuam, lub tshuab laser vuam muaj lub luag haujlwm nrhiav qhov txhaum. Qhov no ua rau nws saib xyuas kev ua haujlwm ntawm lub tshuab tas li, suav nrog cov khoom xws li cov xov hlau, cov khoom siv fais fab, thiab cov tshuab cua txias. Los ntawm kev txheeb xyuas qhov ua tsis zoo lossis kev ua tsis tiav thaum ntxov, cov neeg hlau tuaj yeem ua cov kauj ruam tiv thaiv lossis ceeb toom rau cov neeg ua haujlwm txog qhov teeb meem. Kev tshawb pom thiab daws qhov teeb meem raws sijhawm tuaj yeem pab ua kom muaj txiaj ntsig zoo dua, txo lub sijhawm tsis ua haujlwm thiab ua kom muaj txiaj ntsig ntau dua.

6. Vuam cov hlau nplaum sib cuag thiab rov pib dua tom qab arc tawg:

Ib qho tshwj xeeb ntawm cov neeg hlau laser vuam yog lub peev xwm los tswj cov hlau nplaum sib cuag thiab rov pib dua cov txheej txheem vuam tom qab arc tawg. Lub luag haujlwm vuam hlau nplaum sib cuag ua rau tus neeg hlau hnov thiab kho qhov sib cuag nrog cov hlau vuam, kom ntseeg tau tias qhov zoo tshaj plaws vuam txawm tias rau cov ntaub ntawv nyuaj. Tsis tas li ntawd, lub luag haujlwm rov pib dua arc tawg tso cai rau tus neeg hlau rov pib vuam tom qab kev cuam tshuam ib ntus yam tsis muaj kev cuam tshuam los ntawm tib neeg. Cov yam ntxwv no ua rau cov vuam zoo tas li, txo qhov tsis zoo thiab txhim kho kev ua haujlwm vuam tag nrho.

Xaus lus:

Cov neeg hlau vuam laserMuaj ntau yam ntxwv siab heev uas ua rau kev vuam zoo dua thiab ua rau muaj kev siv tshuab tag nrho hauv ntau yam kev siv. Cov yam ntxwv oscillating ua rau muaj kev npog sai thiab meej, ua kom muaj txiaj ntsig zoo tshaj plaws. Kev tiv thaiv tus kheej, kev ntsuas vuam, kev tiv thaiv kev sib tsoo, kev kuaj pom qhov txhaum thiab lwm yam haujlwm ua kom muaj kev nyab xeeb, raug thiab ua haujlwm tas mus li. Tsis tas li ntawd, kev sib cuag ntawm cov hlau nplaum vuam thiab kev rov pib dua arc pab txhim kho qhov zoo ntawm kev vuam thiab kev ua haujlwm tag nrho. Los ntawm kev siv cov peev xwm siab heev no, cov neeg hlau vuam laser tau hloov pauv qhov chaw vuam ntau heev, ua rau cov chaw tsim khoom ua tiav cov txiaj ntsig vuam zoo dua los ntawm kev ua haujlwm ntau dua thiab kev tsim khoom.

Lub sijhawm tshaj tawm: Lub Yim Hli-03-2023