Rau cov engineers, fabricators, thiab cov thawj coj ua haujlwm, qhov kev sib tw yog tas li: yuav ua li cas koom ua ke cov khoom siv hlau tsis xeb yam tsis muaj kev sib txhuam, kev hloov pauv xim, thiab kev tiv thaiv corrosion txo qis uas cuam tshuam rau cov txheej txheem ib txwm muaj. Cov kev daws teeb meem yoglaser vuam stainless hlau, ib lub thev naus laus zis hloov pauv uas muab kev ceev, kev raug, thiab qhov zoo uas tsis muaj qhov sib piv uas TIG thiab MIG vuam ib txwm tsis tuaj yeem sib piv.

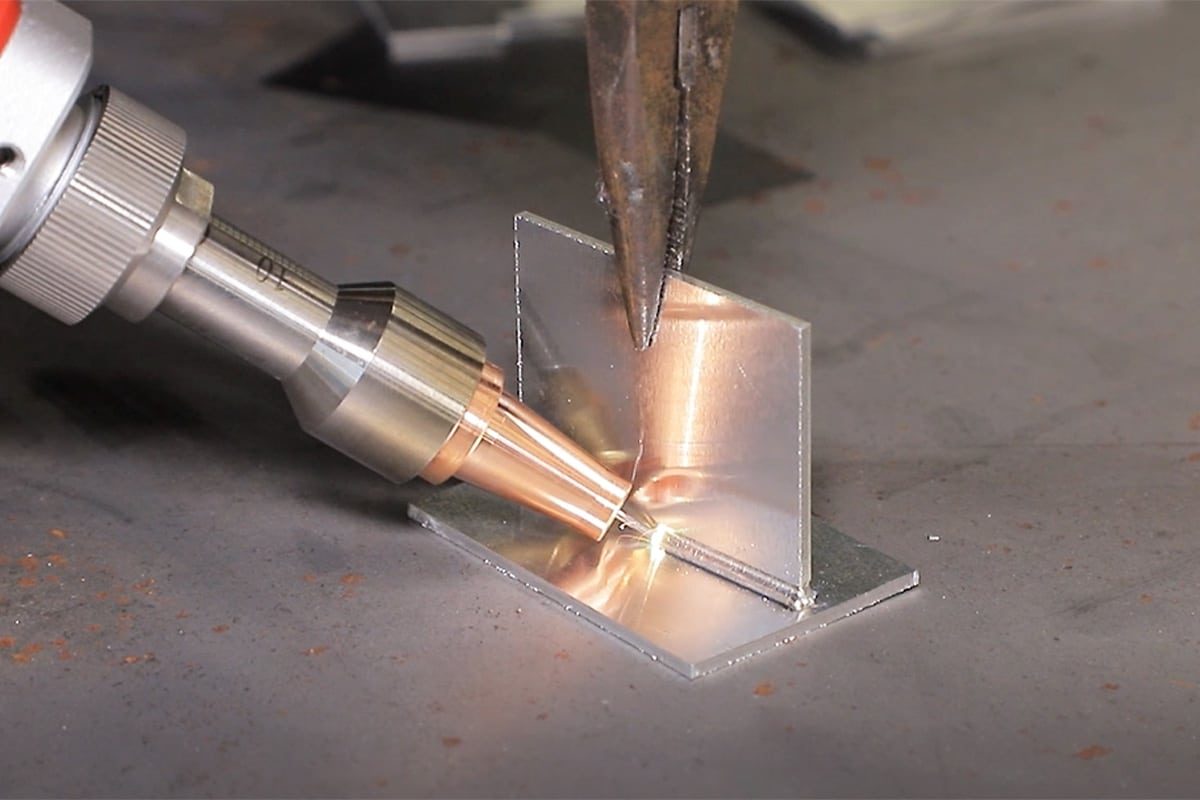

Kev vuam siv laser siv lub teeb ci ntsa iab heev los yaj thiab sib xyaw cov hlau tsis xeb nrog qhov kub tsawg kawg nkaus, tswj tau. Cov txheej txheem no ua raws li qhov tseeb daws tau cov teeb meem tseem ceeb ntawm kev hloov pauv kub thiab qhov ntim vuam.

Cov txiaj ntsig tseem ceeb ntawm Laser Vuam Stainless Steel:

-

Kev Ceev Tshaj Plaws:Ua haujlwm sai dua li TIG vuam 4 txog 10 npaug, ua rau muaj kev tsim khoom thiab kev ua haujlwm ntau dua.

-

Kev Distortion Tsawg Kawg Nkaus:Qhov kub uas tsom mus rau qhov chaw no tsim ib cheeb tsam uas muaj cua sov (HAZ) me me heev, uas ua rau txo lossis tshem tawm qhov warping, thiab tseem khaws qhov tseeb ntawm qhov khoom.

-

Zoo Tshaj Plaws:Tsim cov vuam uas huv si, muaj zog, thiab zoo nkauj uas xav tau me ntsis los yog tsis tas yuav sib tsoo lossis ua tiav tom qab vuam.

-

Cov Khoom Siv Khaws Cia:Qhov cua sov qis ua rau cov hlau tsis xeb muaj zog thiab tiv taus xeb, tiv thaiv cov teeb meem xws li "weld decay".

Phau ntawv qhia no muab cov kev paub txog kev txawj ntse uas xav tau los hloov ntawm kev nkag siab yooj yim mus rau kev siv tau zoo, kom ntseeg tau tias koj tuaj yeem siv tag nrho lub peev xwm ntawm cov txheej txheem tsim khoom siab heev no.

Kev vuam laserpiv rau Cov Txheej Txheem Ib Txwm: Kev Sib Piv Ntawm Lub Taub Hau Mus Rau Lub Taub Hau

Kev xaiv cov txheej txheem vuam zoo yog qhov tseem ceeb rau kev ua tiav ntawm qhov project. Nov yog li cas laser vuam sib piv nrog TIG thiab MIG rau cov ntawv thov stainless hlau.

Laser Vuam vs. TIG Vuam

Tungsten Inert Gas (TIG) vuam yog paub txog cov khoom siv vuam zoo, tes vuam tab sis muaj teeb meem ua kom nrawm hauv qhov chaw tsim khoom.

-

Kev Ceev & Kev Ua Tau Zoo:Kev vuam laser ua haujlwm sai dua, ua rau nws yog qhov kev xaiv meej rau kev siv tshuab thiab kev tsim khoom ntau.

-

Kub thiab Kev Hloov Pauv:Lub TIG arc yog ib qho chaw kub tsis zoo, tsis sib kis uas tsim cov HAZ loj, ua rau muaj kev cuam tshuam loj heev, tshwj xeeb tshaj yog rau ntawm cov hlau nyias. Lub teeb laser tsom mus rau qhov chaw tiv thaiv qhov kev puas tsuaj los ntawm cua sov no.

-

Kev siv tshuab ua haujlwm:Cov tshuab laser yooj yim dua rau kev siv tshuab, ua rau muaj ntau yam khoom ntau, rov ua dua nrog kev txawj ua haujlwm tsawg dua li TIG.

Laser Vuam vs. MIG Vuam

Kev vuam hlau Inert Gas (MIG) yog ib qho txheej txheem uas siv tau ntau yam, muaj kev tso tawm siab, tab sis nws tsis muaj qhov tseeb ntawm laser.

-

Kev Ntsuas & Zoo:Kev vuam laser yog ib qho txheej txheem uas tsis sib chwv uas ua rau cov vuam huv si, tsis muaj cov kab nrib pleb. Kev vuam MIG feem ntau yuav muaj cov kab nrib pleb uas yuav tsum tau ntxuav tom qab vuam.

-

Kev kam rau siab sib txawv:Kev vuam MIG zam txim tau zoo dua rau qhov tsis sib haum xeeb vim tias nws cov hlau siv tau ua lub luag haujlwm tseem ceeb. Kev vuam laser xav tau kev sib dhos kom raug thiab kev kam rau siab.

-

Khoom Siv Thickness:Txawm hais tias cov lasers muaj zog heev tuaj yeem ua haujlwm nrog cov ntu tuab, MIG feem ntau siv tau zoo dua rau cov phaj hnyav heev. Kev vuam laser zoo heev rau cov khoom nyias mus rau nruab nrab qhov twg kev tswj kev cuam tshuam yog qhov tseem ceeb.

Cov Lus Qhia Sib Piv

| Feature | Laser Beam Vuam | Kev vuam TIG | MIG vuam |

| Kev Ceev Vuam | Siab heev (4-10x TIG)

| Qis heev | Siab |

| Thaj Chaw Uas Muaj Kub (HAZ) | Tsawg kawg / nqaim heev | Dav dav | Dav dav |

| Kev Hloov Pauv Kub | Tsis tseem ceeb | Siab | Nruab Nrab mus rau Siab |

| Kev kam rau siab sib txawv | Qis heev (<0.1 hli) | Siab | Nruab nrab |

| Cov Ntaub Ntawv Weld | Nqaim & Tob | Dav & Ntsug | Dav & Hloov Tau |

| Tus nqi khoom siv pib | Siab heev | Qis

| Qis mus rau Nruab Nrab

|

| Zoo Tshaj Plaws Rau | Kev ua kom raug, kev ceev, kev siv tshuab, cov ntaub ntawv nyias

| Kev ua haujlwm tes zoo, zoo nkauj

| Kev tsim khoom dav dav, cov ntaub ntawv tuab |

Kev Tshawb Fawb Tom Qab Kev Sib Txuas: Cov Ntsiab Cai Tseem Ceeb Piav Qhia

Kev nkag siab txog seb lub laser cuam tshuam li cas nrog cov hlau tsis xeb yog qhov tseem ceeb rau kev ua tus thawj coj ntawm cov txheej txheem. Nws feem ntau ua haujlwm hauv ob hom sib txawv txiav txim siab los ntawm lub zog ceev.

Hom Kev Sib Txuas Lus vs. Hom Qhov Tseem Ceeb

-

Kev vuam conduction:Thaum lub zog qis dua, lub laser ua rau cov khoom siv kub, thiab cua sov "coj" mus rau hauv qhov. Qhov no tsim kom muaj qhov vuam ntiav, dav, thiab du zoo nkauj, zoo tagnrho rau cov khoom siv nyias (qis dua 1-2 hli) lossis cov seams pom qhov twg qhov tsos yog qhov tseem ceeb.

-

Kev Vuam Qhov (Kev Nkag Mus Tob)Thaum muaj zog ntau dua (kwv yees li 1.5 MW/cm²), lub laser yuav ua rau cov hlau vaporizes tam sim ntawd, tsim ib lub qhov tob, nqaim hu ua "keyhole." Lub qhov keyhole no ntes lub zog laser, thiab xa nws mus rau hauv cov khoom kom muaj zog, nkag mus rau hauv cov qhov welds hauv cov ntu tuab dua.

Kev Sib Txuas Nruag Nruag (CW) vs. Pulsed Lasers

-

Ntxuam Ntxuam (CW):Lub laser xa ib lub zog tsis tu ncua, tsis muaj kev cuam tshuam. Hom no zoo meej rau kev tsim cov xov ntev, txuas ntxiv mus ntawm qhov ceev siab hauv kev tsim khoom tsis siv neeg.

-

Laser pulsed:Lub laser xa lub zog hauv luv luv, muaj zog heev. Txoj hauv kev no muab kev tswj hwm qhov kub nkag, txo qhov HAZ thiab ua rau nws zoo tagnrho rau kev vuam cov khoom me me, cov khoom rhiab heev rau cua sov lossis tsim cov chaw vuam sib tshooj rau lub foob zoo meej.

Ib Kauj Ruam Qhia Txog Kev Npaj Zoo Kawg Nkaus

Hauv kev vuam laser, kev vam meej yog txiav txim siab ua ntej lub teeb raug qhib. Qhov kev ua kom raug ntawm cov txheej txheem xav tau kev npaj ua tib zoo.

Kauj Ruam 1: Tsim Kev Sib Koom Tes thiab Kev Sib Haum

Tsis zoo li arc welding, laser welding muaj kev kam rau siab tsawg heev rau qhov sib txawv lossis kev tsis sib haum.

-

Hom Sib Koom Tes:Cov pob qij txha uas muaj qhov zoo tshaj plaws tab sis yuav tsum muaj qhov sib txawv ze li xoom (feem ntau tsawg dua 0.1 hli rau cov ntu nyias). Cov pob qij txha hauv lub duav zam txim rau qhov sib txawv ntawm qhov haum.

-

Kev Tswj Qhov Sib Txawv:Yog tias muaj qhov sib txawv ntau dhau, cov dej me me uas yaj yuav tsis txuas tau qhov sib txuas, ua rau kev sib txuas tsis tiav thiab kev sib txuas tsis zoo. Siv cov txheej txheem txiav uas raug siab thiab kev clamping ruaj khov kom ntseeg tau tias sib phim zoo.

Kauj Ruam 2: Kev Ntxuav Qhov Chaw Thiab Kev Tshem Tawm Cov Khoom Phem

Lub zog muaj zog ntawm lub laser yuav ua rau cov pa phem ntawm qhov chaw, ua rau lawv nyob hauv qhov vuam thiab ua rau muaj qhov tsis zoo xws li porosity.

-

Kev huv si yog qhov tseem ceeb:Qhov saum npoo yuav tsum tsis muaj roj, roj av, hmoov av, thiab cov khoom seem nplaum kiag li.

-

Txoj Kev Ntxuav:Siv daim ntaub tsis muaj plaub uas ntub cov tshuaj yaj uas yaj tau yooj yim xws li acetone lossis 99% isopropyl cawv los so qhov chaw sib txuas tam sim ntawd ua ntej vuam.

Kev Tswj Lub Tshuab: Kev Txhim Kho Cov Qauv Vuam Tseem Ceeb

Kev ua tiav qhov vuam zoo meej yuav tsum tau sib npaug ntawm ntau yam sib txuas.

Cov Txheej Txheem Peb Yam: Lub Hwj Chim, Kev Ceev, thiab Qhov Chaw Pom Kev

Peb qhov chaw no ua ke txiav txim siab qhov nkag ntawm lub zog thiab qhov profile vuam.

-

Lub zog laser (W):Lub zog siab dua ua rau nkag mus tob dua thiab ua kom nrawm dua. Txawm li cas los xij, lub zog ntau dhau tuaj yeem ua rau hlawv tag rau ntawm cov ntaub nyias nyias.

-

Vuam Ceev (hli/s):Qhov ceev dua txo qhov kub nkag thiab kev cuam tshuam. Yog tias qhov ceev siab dhau rau qib fais fab, nws tuaj yeem ua rau nkag mus tsis tiav.

-

Qhov Chaw Tseem Ceeb:Qhov no kho qhov loj ntawm qhov chaw laser thiab lub zog ceev. Kev tsom mus rau saum npoo tsim qhov vuam tob tshaj plaws thiab nqaim tshaj plaws. Kev tsom mus rau saum npoo (positive defocus) tsim qhov vuam zoo nkauj dav dua, ntiav dua. Kev tsom mus rau hauv qab npoo (negative defocus) tuaj yeem ua rau nkag mus rau hauv cov ntaub ntawv tuab.

Kev Xaiv Roj Tiv Thaiv: Argon vs. Nitrogen

Cov pa roj tiv thaiv tiv thaiv lub pas dej vuam uas yaj los ntawm kev ua qias tuaj hauv huab cua thiab ua kom cov txheej txheem ruaj khov.

-

Argon (Ar):Qhov kev xaiv feem ntau, muab kev tiv thaiv zoo heev thiab tsim cov vuam ruaj khov, huv si.

-

Nitrogen (N2):Feem ntau nyiam siv cov hlau tsis xeb, vim nws tuaj yeem ua kom qhov sib koom ua ke kawg tsis kam xeb.

-

Tus Nqi Nqus:Yuav tsum tau ua kom zoo tshaj plaws. Yog tias tsawg dhau yuav tiv thaiv tsis tau qhov vuam, thaum ntau dhau yuav ua rau muaj kev kub ntxhov thiab rub cov pa phem. Qhov pib ntawm qhov ntws yog 10 txog 25 litres ib feeb (L/min) feem ntau.

Cov Ntsiab Lus Pib ntawm Parameter: Ib Daim Ntawv Qhia Txog

Cov hauv qab no yog cov ntsiab lus pib dav dav rau kev vuam 304/316 austenitic stainless hlau. Ib txwm ua qhov kev sim rau cov khoom seem kom zoo rau koj daim ntawv thov tshwj xeeb.

| Khoom Siv Thickness (hli) | Lub zog laser (W) | Vuam Ceev (hli/s) | Qhov Chaw Ua Kom Pom Tseeb | Cov roj tiv thaiv |

| 0.5 | 350 – 500 | 80 – 150 | Nyob rau saum npoo | Argon los yog Nitrogen |

| 1.0 | 500 – 800 | 50 – 100 | Nyob rau saum npoo | Argon los yog Nitrogen |

| 2.0 | 800 – 1500 | 25 – 60 | Me ntsis hauv qab nto | Argon los yog Nitrogen |

| 3.0 | 1500 – 2000 | 20 – 50 | Hauv qab nto | Argon los yog Nitrogen |

| 5.0 | 2000 – 3000 | 15 – 35 | Hauv qab nto | Argon los yog Nitrogen |

Kev Tswj Xyuas Zoo: Ib Daim Ntawv Qhia Txog Kev Teeb Meem rau Cov Kev Tsis Zoo Feem Ntau

Txawm tias muaj cov txheej txheem meej meej los xij, qhov tsis zoo kuj tseem tuaj yeem tshwm sim. Kev nkag siab txog lawv qhov ua rau yog qhov tseem ceeb rau kev tiv thaiv.

Kev Txheeb Xyuas Cov Kev Tsis Zoo ntawm Laser Welding

-

Qhov porosity:Cov pa roj me me uas raug kaw hauv qhov vuam, feem ntau yog los ntawm kev ua qias tuaj ntawm qhov chaw lossis cov pa roj tsis zoo.

-

Kub tawg:Cov kab nrib pleb hauv nruab nrab uas tsim thaum lub vuam khov kho, qee zaum vim yog cov khoom siv sib xyaw lossis kev ntxhov siab thermal siab.

-

Kev Nkag Mus Tsis Tag Nrho:Cov hlau txuas tsis sib txuas thoob plaws qhov tob ntawm qhov sib koom ua ke, feem ntau yog vim muaj zog tsis txaus lossis ceev dhau.

-

Txiav qis dua:Ib qho zawj yaj rau hauv cov hlau hauv paus ntawm ntug ntawm qhov vuam, feem ntau yog tshwm sim los ntawm kev khiav ceev dhau lossis qhov sib txawv loj.

-

Cov dej tawg:Cov dej me me uas yaj tawm ntawm lub pas dej vuam, feem ntau yog los ntawm lub zog ntau dhau lossis kev ua qias tuaj ntawm qhov chaw.

Daim Ntawv Qhia Txog Kev Teeb Meem: Cov Ua Rau Thiab Cov Kev Daws Teeb Meem

| Qhov tsis zoo | Tej zaum yuav muaj tej yam ua rau muaj teeb meem | Cov Kev Kho Kom Zoo Uas Pom Zoo |

| Qhov porosity | Kev ua qias tuaj ntawm qhov chaw; cov pa roj tsis zoo tiv thaiv. | Ua kom huv si ua ntej vuam; xyuas kom tseeb tias cov roj raug thiab ua kom qhov nrawm ntawm cov khoom ntws zoo. |

| Kub Cracking | Cov khoom siv yoo puas tsuaj; kev ntxhov siab thermal siab. | Siv cov hlau nplaum kom tsim nyog; preheat cov khoom kom txo tau thermal shock. |

| Kev Nkag Mus Tsis Tiav | Tsis muaj zog txaus; khiav ceev dhau; tsis tsom ntsoov zoo. | Ua kom lub zog laser nce lossis txo qhov ceev ntawm kev vuam; xyuas kom meej thiab kho qhov chaw tsom. |

| Txiav qis dua | Khiav ceev dhau; qhov sib txawv loj ntawm cov pob qij txha. | Txo qhov ceev ntawm kev vuam; txhim kho qhov haum ntawm ib feem kom txo qhov sib txawv. |

| Spatter | Lub zog ceev dhau; kev ua qias tuaj ntawm qhov chaw. | Txo lub zog laser lossis siv qhov tsis pom kev zoo; xyuas kom meej tias cov chaw huv si. |

Cov Kauj Ruam Kawg: Kev Ntxuav Tom Qab Weld thiab Passivation

Cov txheej txheem vuam ua puas rau cov khoom uas ua rau cov hlau tsis xeb "stainless." Kev kho kom rov qab zoo li qub yog ib kauj ruam kawg uas yuav tsum tau ua.

Vim Li Cas Koj Thiaj Tsis Txhob Dhia Kev Kho Mob Tom Qab Weld

Cov cua sov los ntawm kev vuam ua rau cov txheej chromium-oxide uas tsis pom thiab tiv thaiv ntawm qhov chaw ntawm cov hlau puas tsuaj. Qhov no ua rau qhov vuam thiab HAZ nyob ib puag ncig yooj yim rau xeb thiab xeb.

Cov Txheej Txheem Passivation Piav Qhia

Passivation yog ib txoj kev kho mob uas tshem tawm cov pa phem ntawm qhov chaw thiab pab kho kom zoo dua qub, muaj zog thiab sib xws ntawm cov chromium-oxide txheej.

-

Kev Siv Tshuaj Pickling:Ib txoj kev ib txwm siv cov kua qaub txaus ntshai xws li nitric thiab hydrofluoric acid los ntxuav thiab ua kom qhov chaw tsis muaj zog.

-

Kev Ntxuav Hluav Taws Xob:Ib txoj kev niaj hnub, muaj kev nyab xeeb dua, thiab sai dua uas siv cov kua electrolytic me me thiab cov hluav taws xob qis los ntxuav thiab passivate qhov vuam hauv ib kauj ruam xwb.

Kev Nyab Xeeb Ua Ntej: Cov Kev Ceev Faj Tseem Ceeb rau Laser Welding

Qhov xwm txheej siab ntawm kev vuam laser ua rau muaj kev phom sij loj heev rau kev ua haujlwm uas xav tau cov txheej txheem kev nyab xeeb nruj.

Qhov Txaus Ntshai Zais Cia: Cov Pa Hexavalent Chromium (Cr(VI))

Thaum cov hlau tsis xeb raug cua sov rau qhov kub vuam, cov chromium hauv cov hlau sib xyaw tuaj yeem tsim cov hexavalent chromium (Cr(VI)), uas dhau los ua huab cua hauv cov pa phem.

-

Kev Pheej Hmoo Kev Noj Qab Haus Huv:Cr(VI) yog ib yam tshuaj uas ua rau mob qog nqaij hlav hauv tib neeg uas muaj feem yuav mob qog nqaij hlav hauv lub ntsws. Nws kuj tseem ua rau mob ntsws, tawv nqaij, thiab qhov muag heev.

-

Cov Kev Txwv Kev Raug:OSHA teem ib qho kev txwv tsis pub muaj Cr(VI) ntau tshaj 5 micrograms ib cubic meter ntawm huab cua (5 µg/m³).

Cov Kev Ntsuas Kev Nyab Xeeb Tseem Ceeb

-

Kev Tswj Xyuas Kev Tsim Kho:Txoj kev zoo tshaj plaws los tiv thaiv cov neeg ua haujlwm yog ntes qhov txaus ntshai ntawm nws qhov chaw. Kev ua haujlwm zoolub tshuab rho pa tawmnrog rau lub lim dej HEPA ntau theem yog qhov tseem ceeb rau kev ntes cov khoom me me uas tsim los ntawm laser vuam.

-

Cov Khoom Siv Tiv Thaiv Tus Kheej (PPE):Txhua tus neeg ua haujlwm hauv thaj chaw yuav tsum hnav cov tsom iav laser uas ntsuas rau qhov ntev ntawm lub laser. Yog tias kev rho pa tawm tsis tuaj yeem txo qhov kev raug hluav taws xob qis dua PEL, yuav tsum muaj cov cuab yeej ua pa uas tau pom zoo. Kev ua haujlwm vuam kuj tseem yuav tsum tau ua nyob rau hauv lub qhov rooj tiv thaiv lub teeb nrog kev sib txuas kev nyab xeeb kom tiv thaiv kev raug hluav taws xob tsis tau xav txog.

Cov Lus Nug Feem Ntau (FAQ)

Hom laser zoo tshaj plaws rau kev vuam stainless hlau yog dab tsi?

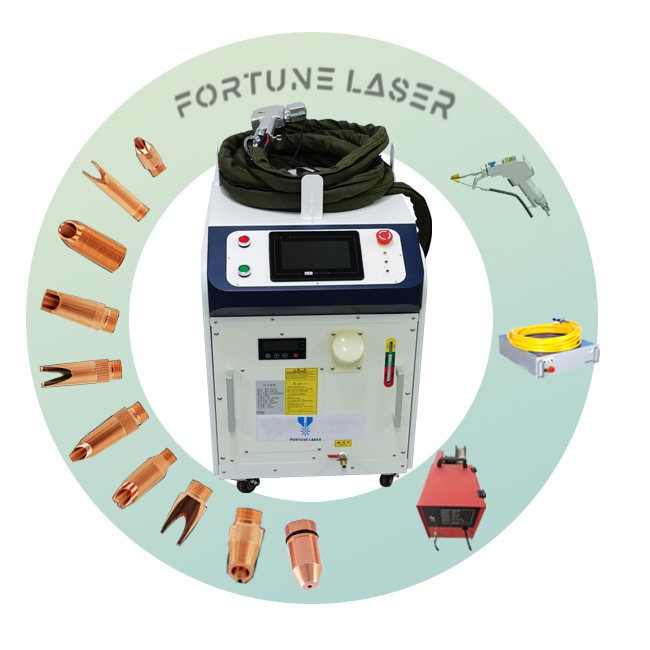

Cov lasers fiber feem ntau yog qhov kev xaiv zoo tshaj plaws vim lawv cov wavelength luv dua, uas cov hlau tsis xeb yooj yim nqus tau, thiab lawv cov beam zoo heev rau kev tswj hwm meej.

Koj puas tuaj yeem laser vuam cov hlau stainless hlau sib txawv tuab ua ke?

Yog lawm, laser vuam zoo heev ntawm kev koom ua ke cov tuab sib txawv nrog qhov tsis sib xws tsawg kawg thiab tsis muaj hlawv-dhau ntawm qhov nyias dua, ib txoj haujlwm uas nyuaj heev nrog TIG vuam.

Puas yog cov hlau nplaum tsim nyog rau laser vuam stainless hlau?

Feem ntau, tsis muaj. Kev vuam laser tuaj yeem tsim cov vuam muaj zog, nkag mus tag nrho yam tsis muaj cov khoom siv filler (autogenously), uas ua rau cov txheej txheem yooj yim dua. Cov hlau filler siv thaum qhov kev tsim sib koom ua ke muaj qhov sib txawv loj dua lossis thaum xav tau cov khoom siv hlau tshwj xeeb.

Qhov tuab tshaj plaws ntawm cov hlau tsis xeb uas tuaj yeem laser welded yog dab tsi?

Nrog cov tshuab muaj zog heev, nws muaj peev xwm vuam cov hlau tsis xeb txog li 1/4″ (6mm) lossis tuab dua hauv ib zaug dhau. Cov txheej txheem hybrid laser-arc tuaj yeem vuam cov ntu uas tuab dua ib nti.

Xaus lus

Qhov zoo ntawm kev vuam laser hauv kev ceev, kev raug, thiab qhov zoo ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev tsim cov hlau stainless niaj hnub. Nws ua rau muaj cov pob qij txha muaj zog dua, huv dua tab sis tsis muaj kev cuam tshuam ntau, khaws cov khoom kom zoo thiab zoo nkauj.

Txawm li cas los xij, kev ua tiav cov txiaj ntsig zoo tshaj plaws hauv ntiaj teb no nyob ntawm seb yuav ua li cas. Kev vam meej yog qhov kawg ntawm kev tsim khoom siv siab-los ntawm kev npaj sib koom ua ke thiab kev tswj hwm cov txheej txheem mus rau kev yuam kom ua kom tiav tom qab vuam thiab kev cog lus ruaj khov rau kev nyab xeeb. Los ntawm kev ua tus thawj coj ntawm cov txheej txheem no, koj tuaj yeem qhib qib tshiab ntawm kev ua haujlwm zoo thiab zoo hauv koj cov haujlwm.

Lub sijhawm tshaj tawm: Lub Kaum Hli-08-2025