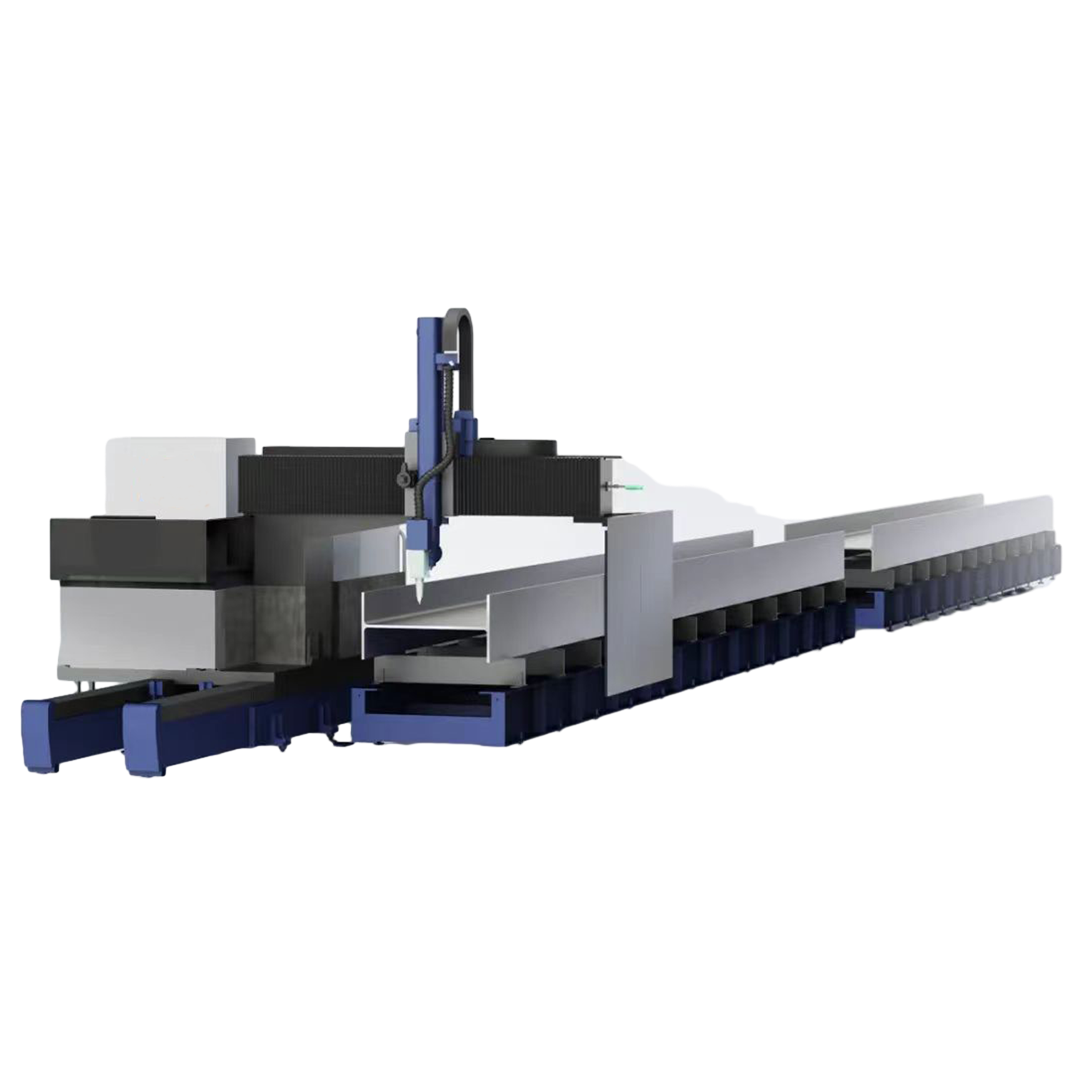

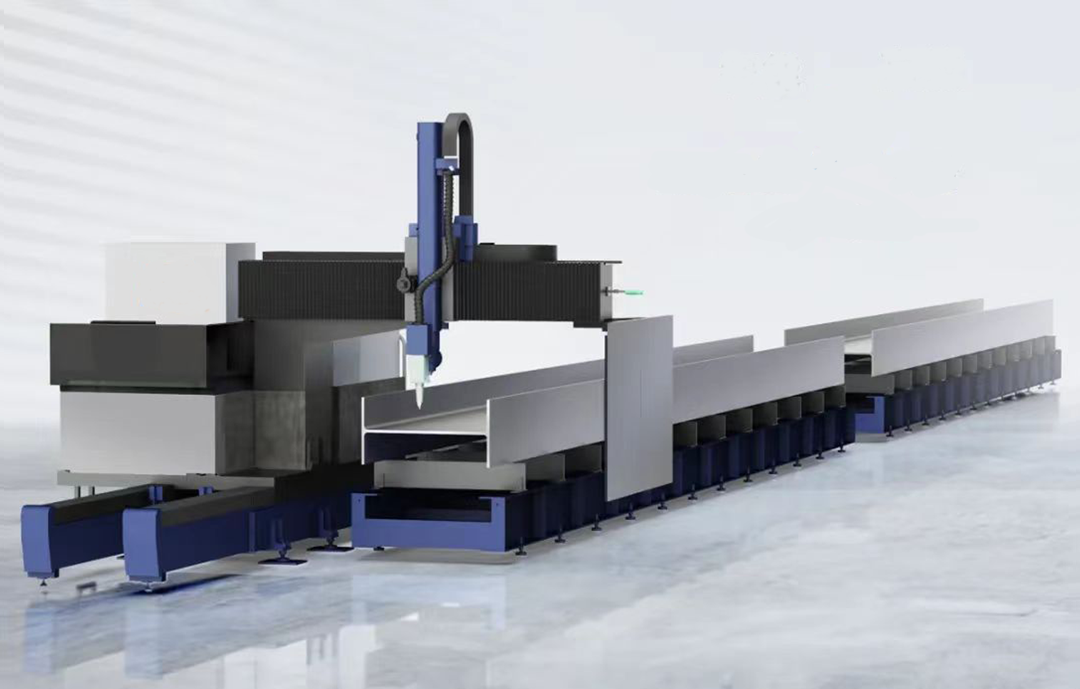

Fortune Laser Kev Ua Haujlwm CNC 3D 5-Axis H Beam Laser Cutting System Tshuab

Fortune Laser Kev Ua Haujlwm CNC 3D 5-Axis H Beam Laser Cutting System Tshuab

Cov Cim Tshuab

Lub tshuab txiav hlau/phaj tiaj tiaj/bevel loj 12m/24m siv lub tshuab German Beckhoff peb-seem tsib-axis. Cov kab ntau lawm laser txiav peb-hauv-ib yog cov khoom siv thev naus laus zis siab uas koom ua ke peb-seem tsib-axis RTCP CNC thev naus laus zis, txiav laser, tshuab precision, thiab thev naus laus zis nrhiav ntse. Hauv kev ua cov qauv hlau, kev siv tes ib txwm muaj, txiav nplaim taws, txiav plasma, thiab cov txheej txheem thauj khoom thiab tshem tawm semi-automatic tseem siv los txhim kho qhov zoo thiab kev ua haujlwm ntawm cov qauv hlau ua cov khoom lag luam thiab txo cov nqi zog ua haujlwm.

Cov kab ntau lawm laser txiav peb-hauv-ib muaj kev hloov pauv tau zoo thiab tuaj yeem hloov kho. Nws yog dav siv hauv kev lag luam tsim khoom siv xws li cov qauv hlau, nkoj, tshuab engineering, tshuab ua liaj ua teb, hluav taws xob cua, roj av, kev lag luam tshuaj lom neeg, thiab kev tsim kho hauv hiav txwv. Nws yog dav siv los ua cov hlau H-zoo li tus, kev lag luam Laser txiav ntawm cov hlau hla ntu, C-zoo li tus hlau, square hlau, nkhaus hlau, channel hlau, thiab lwm yam.

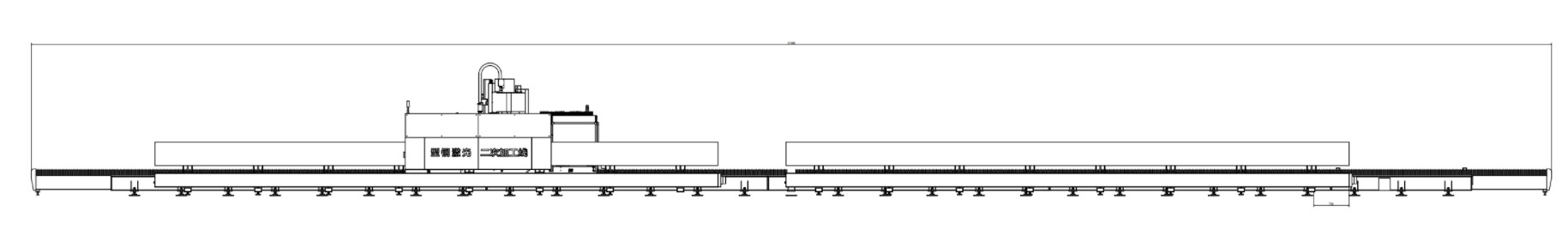

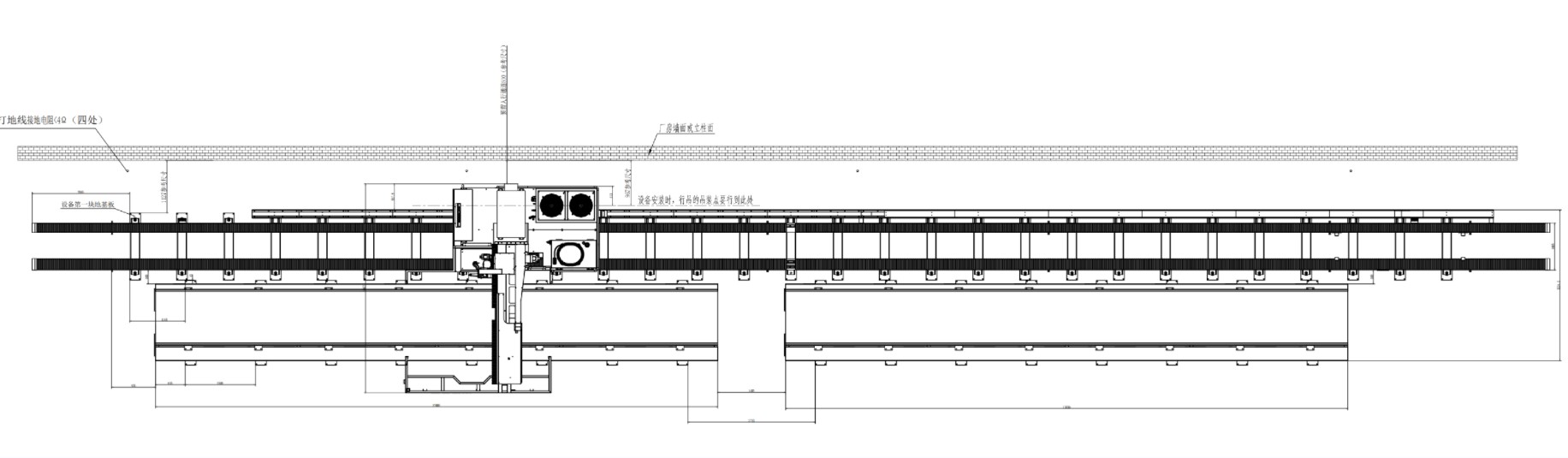

Kev teeb tsa tshuab

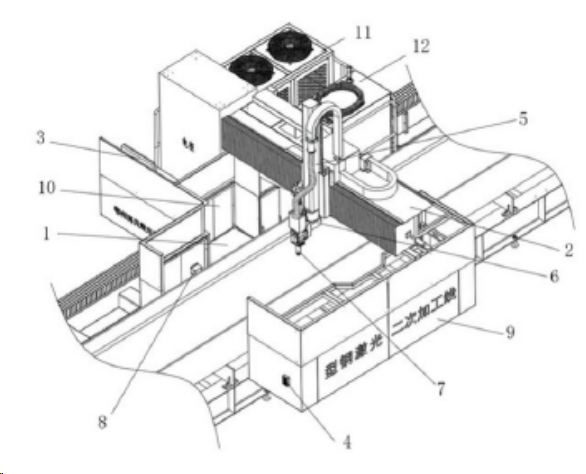

Kev tsim cov txheej txheem thiab kev ua haujlwm

Cov yam ntxwv ntawm tshuab

1. Tsiv lub platform

2. Lub thav duab Cantilever

3. Chaw Tswj Xyuas

4. Chaw taws teeb tswj

5. Z axis

6. AC axis

7. Txiav taub hau

8. Lub tshuab ntsuas laser

9. Lub hau tiv thaiv

10. Cov ntaub thaiv graphite

11. Lub tshuab dej txias

12. Lub zog laser

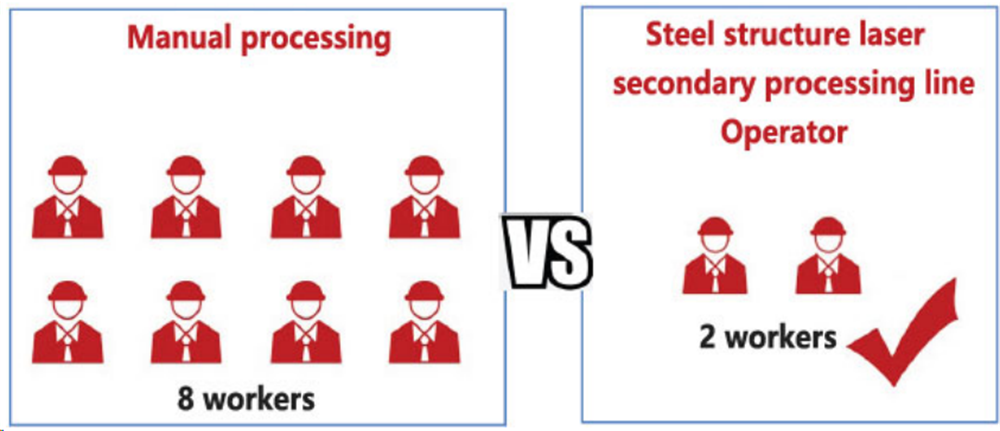

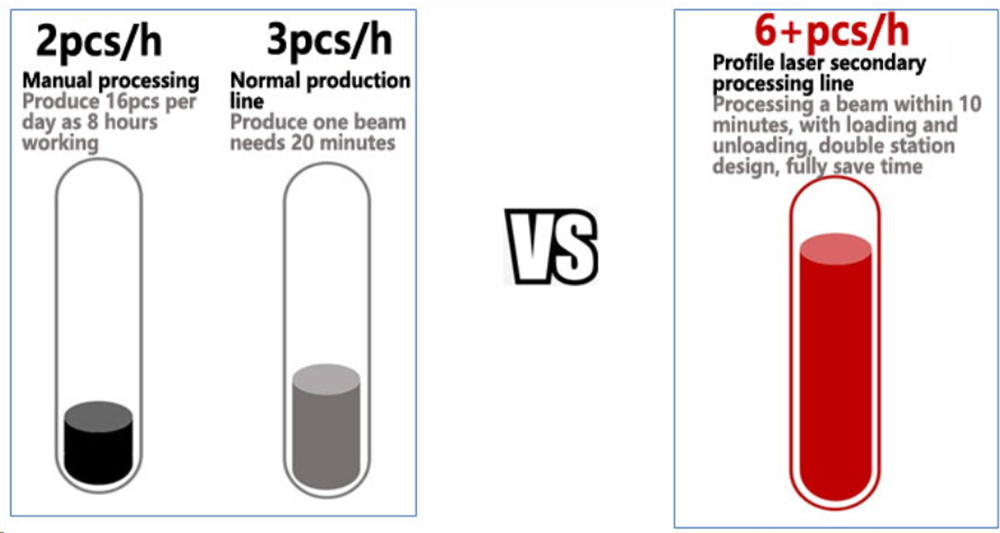

Piv nrog rau kev ua tes ua ib txwm muaj

Lub Multi-module CW Fiber Lasers tsim los ntawm Raycus yog nrog kev hloov pauv hluav taws xob zoo, lub teeb ci zoo, lub zog ceev, zaus hloov kho dav, kev ntseeg siab siab, lub neej ntev, kev ua haujlwm tsis tas yuav saib xyuas thiab cov txiaj ntsig. Cov khoom no tuaj yeem siv dav hauv kev vuam, kev txiav txim siab, yaj thiab cladding, kev ua tiav ntawm qhov chaw, 3D luam ntawv thiab lwm yam teb. Nws cov txiaj ntsig tso zis optical pab nws sib xyaw zoo dua nrog cov neeg hlau ua cov khoom siv tsim khoom yooj ywm kom tau raws li qhov xav tau ua tiav 3D.

Cov yam ntxwv ntawm cov khoom:

➣ Kev hloov pauv hluav taws xob zoo heev

➣ Qhov ntev ntawm cov khoom siv fiber ntau tuaj yeem hloov kho tau

➣ QD txuas

➣ kev ua haujlwm tsis tas yuav saib xyuas

➣ Ntau qhov zaus hloov kho ntau yam

➣ muaj peev xwm tiv thaiv kev ua xua siab

➣ Kev txiav ntawv zoo

Cov ntaub ntawv siv ntawm lub tshuab laser:

| Lub Npe | Hom | Cov Qauv |

| Cov cuab yeej siv laser (Raycus 12000W fiber laser) | Qhov ntev ntawm nthwv dej | 1080 ± 5nm |

| Cov zis ntsuas | 12000W | |

| Qhov zoo ntawm lub teeb (BPP) | 2-3 (75μm) / 3-3.5 (100μm) | |

| Txoj kev ua haujlwm laser | Kev kho kom zoo tas li | |

| Txoj kev txias | Dej txias | |

| Kev txiav siab tshaj plaws (Thaum txiav cov phaj tuab, vim yog cov khoom siv thiab lwm yam laj thawj, tej zaum yuav muaj burrs) | CS: ≤30mmSS: ≤30mm |

Lub zog laser (Xaiv 2)

Cov Multi-module CW Fiber Lasers uas Raycus tsim muaj txij li 3,000W txog 30kW, nrog rau kev hloov pauv hluav taws xob zoo, lub teeb ci zoo, lub zog ceev, zaus hloov kho dav, kev ntseeg siab, lub neej ntev, kev ua haujlwm tsis tas yuav saib xyuas thiab cov txiaj ntsig. Cov khoom no tuaj yeem siv dav hauv kev vuam, kev txiav txim siab, yaj thiab cladding, kev ua tiav ntawm qhov chaw, 3D luam ntawv thiab lwm yam teb. Nws cov txiaj ntsig tso zis optical pab nws sib xyaw zoo dua nrog cov neeg hlau ua cov khoom siv tsim khoom yooj ywm kom tau raws li qhov xav tau ua tiav 3D.

Cov yam ntxwv ntawm cov khoom:

➣ Kev hloov pauv hluav taws xob zoo heev

➣ Qhov ntev ntawm cov khoom siv fiber ntau tuaj yeem hloov kho tau

➣ QD txuas

➣ kev ua haujlwm tsis tas yuav saib xyuas

➣ Ntau qhov zaus hloov kho ntau yam

➣ muaj peev xwm tiv thaiv kev ua xua siab

➣ Kev txiav ntawv zoo

Cov ntaub ntawv siv ntawm lub tshuab laser:

| Lub Npe | Hom | Cov Qauv |

| Cov cuab yeej siv laser (Raycus 20000W fiber laser) | Qhov ntev ntawm nthwv dej | 1080 ± 5nm |

| Cov zis ntsuas | 20000W/30000W | |

| Qhov zoo ntawm lub teeb (BPP) | 2-3 (75μm) / 3-3.5 (100μm) | |

| Txoj kev ua haujlwm laser | Kev kho kom zoo tas li | |

| Txoj kev txias | Dej txias | |

| Kev txiav siab tshaj plaws (Thaum txiav cov phaj tuab, vim yog cov khoom siv thiab lwm yam laj thawj, tej zaum yuav muaj burrs) | CS: ≤50mmSS: ≤40mm |

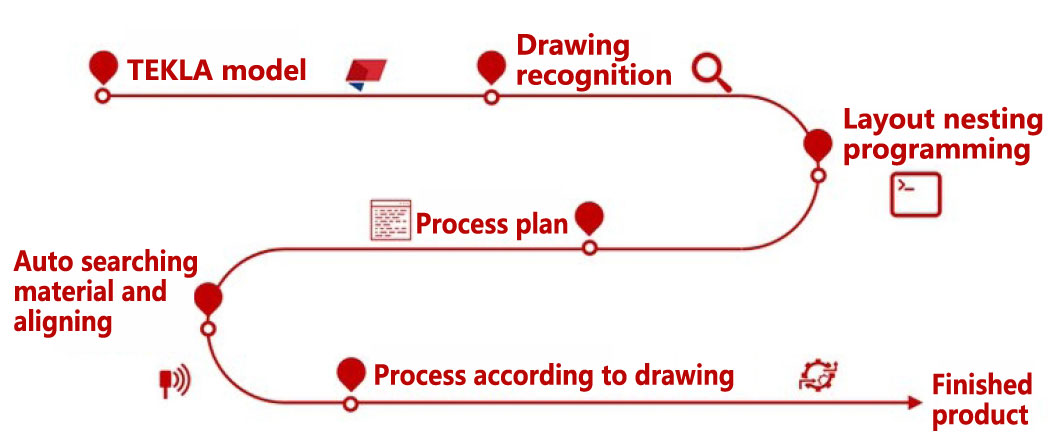

Kev tswj software thiab nesting software

Lub tshuab ua haujlwm CNC siv lub tshuab ua haujlwm laser theem ob ntawm cov hlau zoo li tus qauv tsim los ntawm Fortune Laser, uas yooj yim rau kev khiav lag luam, ruaj khov rau kev khiav thiab muaj kev ua tau zoo heev.

➣ Nws muaj lub tsev qiv ntawv txiav cov txheej txheem los pab cov neeg siv ua tiav qhov zoo tshaj plaws txiav.

➣ Kos lossis hloov kho cov duab 2D ncaj qha hauv lub tshuab ua haujlwm yam tsis tas yuav siv software thib peb, ua kom muaj kev tsim khoom ntau ntxiv thiab muab kev suav asymmetric acceleration thiab deceleration rau silky lubrication.

➣ Lub tshuab hluav taws xob ua kom lub neej khoom siv zoo dua.

➣ Nws muab cov haujlwm modular txheem xws li ib-nias txiav-tawm, tsis siv neeg calibration, thiab cheeb tsam plua plav extraction.

➣ Lub phaj nyias nyias uas tsis yog inductive perforation, lub phaj tuab xob laim perforation, ntau theem perforation, perforation slag tshem tawm, kev tswj kev co, lub voj voog kaw siab, txheej faib thev naus laus zis zoo thiab lwm yam haujlwm zoo heev txhim kho kev ua haujlwm zoo thiab kev ruaj khov ntawm kev txiav fais fab siab, txhim kho qhov kev sib tw tseem ceeb ntawm cov khoom siv.

➣ Kev ceev ceev thiab qhov tseeb siab tsis siv neeg nrhiav ntug kom ua tau raws li qhov xav tau ntawm cov ntaub ntawv profiled thiab qhov tseeb siab dua.

➣ Paub txog kev cuam tshuam kev sib kis ntev ntev ntawm cov teeb liab tso saib, IO teeb liab thiab USB teeb liab.

➣ Torque deviation tiv thaiv kev sib tsoo, kev tiv thaiv kev cuam tshuam ntawm huab cua, kev dhia ntse thiab lwm yam haujlwm.

Cov software nesting siv cov software tshwj xeeb rau cov kab ua haujlwm laser theem nrab ntawm cov hlau profile, uas yooj yim rau kev khiav lag luam, nrog rau kev ua haujlwm txheeb xyuas tsis siv neeg thiab kev ua cov ntaub ntawv batch sai.

➣ txhawb nqa kev xa khoom ncaj qha ntawm Tekla, Solidworks thiab lwm yam qauv 3D, thiab tuaj yeem kos lossis hloov kho daim duab qhia kev txiav ntawm seem hlau hauv software nesting, tsis tas yuav koom tes nrog software thib peb, txhim kho kev debugging thiab kev hloov kho kom zoo.

➣ hloov lossis ua cov ntaub ntawv ua pawg, txhawb kev ua tiav ntawm ntau lub nodes txuas nrog, thiab cia li kho cov kev txiav kom zoo dua los txhawb kev txiav ntug.

➣ Cov software muaj kev ruaj khov siab, thiab cov txheej txheem database sib xws tuaj yeem teeb tsa raws li cov ntaub ntawv sib txawv thiab phaj tuab.

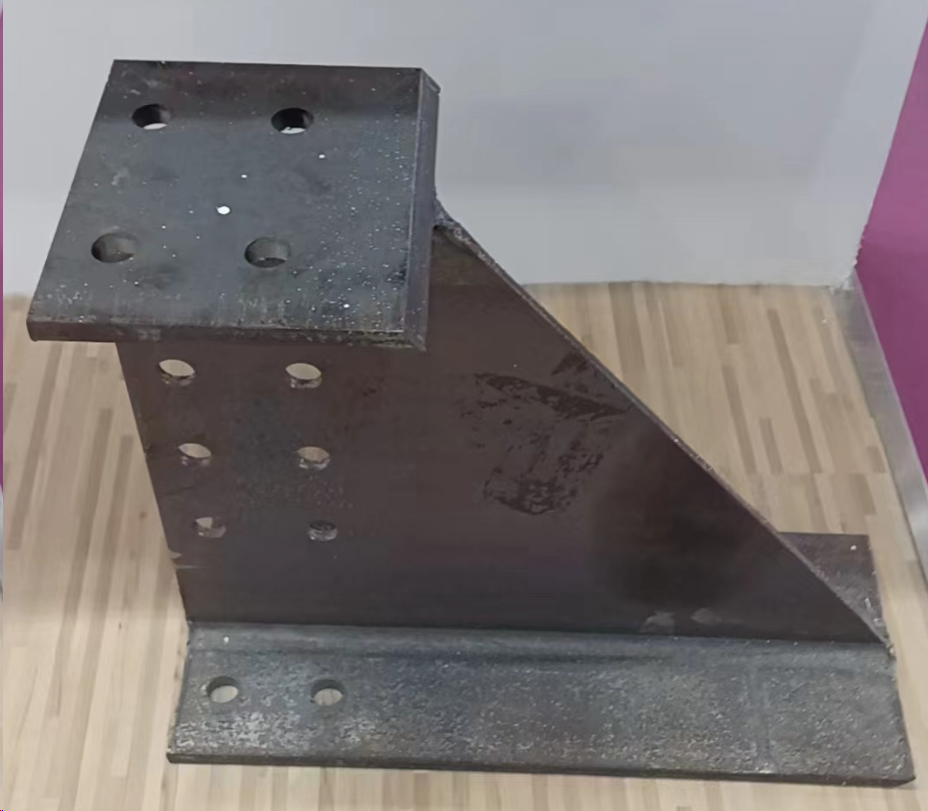

Cov Kev Siv Tshuab

Tshuab Zaub

Cov Qauv Zaub

Kev sib dhos meej thiab kev teeb tsa yooj yim

Los ntawm kev vuam qhov txiav zaub raws li saum toj no

Seem hlau 45 degree bevel txiav zaub