Mīkini Kuʻi Paepae Hoʻomau ʻo Fortune Laser 1000W/1500W/2000W Fiber Laser

Mīkini Kuʻi Paepae Hoʻomau ʻo Fortune Laser 1000W/1500W/2000W Fiber Laser

Nā Kumumanaʻo Kumu o ka Mīkini Laser

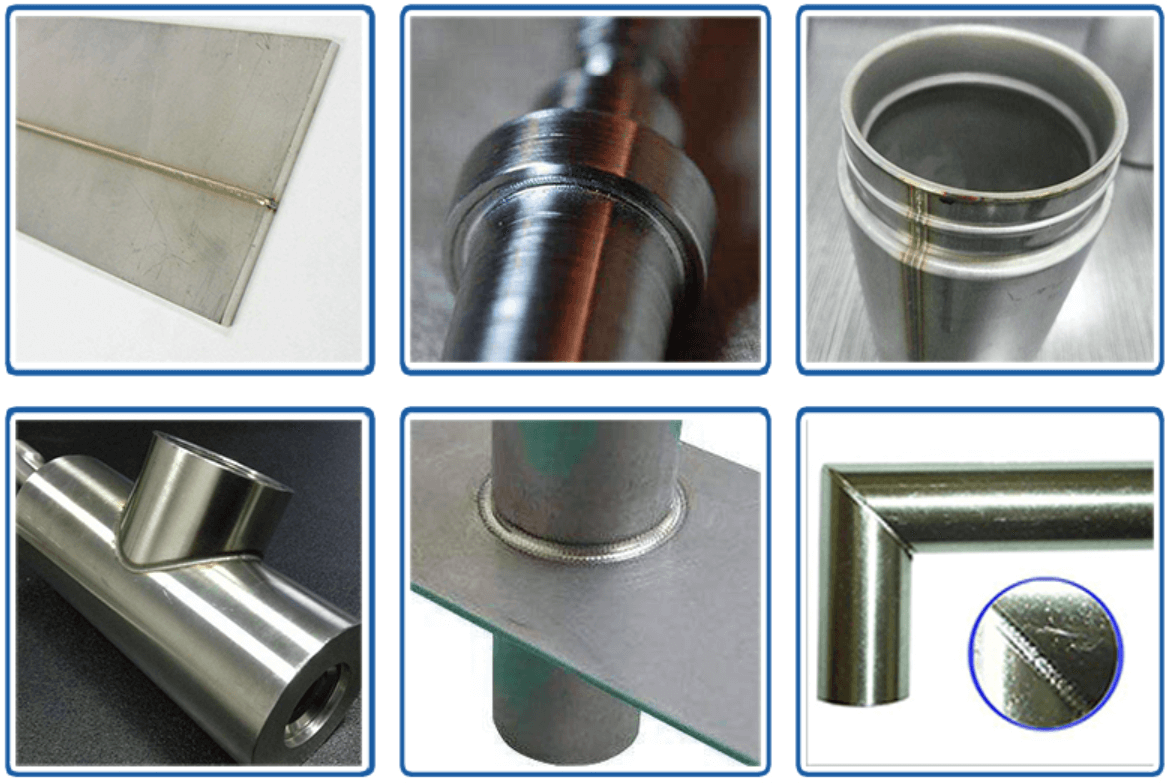

ʻO ka mīkini wili laser fiber hoʻomau he ʻano hana wili hou. Hoʻokumu ʻia ia me kahi "host wili" a me kahi "workbench wili". Hoʻopili ʻia ke kukuna laser i ka fiber optical. Ma hope o ka hoʻoili ʻana i kahi mamao loa, hana ʻia i mea e kālele ana i ke kukui like. Hana ʻia ka wili hoʻomau ma ka workpiece. Ma muli o ka hoʻomau ʻana o ke kukui, ʻoi aku ka ikaika o ka hopena wili a ʻoi aku ka maikaʻi a me ka nani o ka humuhumu wili. Wahi a nā pono like ʻole o nā ʻoihana like ʻole, hiki i nā lako wili laser ke hoʻohālikelike i ke ʻano a me ka workbench e like me ke kahua hana a hoʻokō i ka hana aunoa, hiki ke hoʻokō piha i nā pono o nā mea hoʻohana ma nā ʻoihana like ʻole.

ʻO ka hapa nui o nā mīkini wili laser fiber hoʻomau e hoʻohana i nā lasers mana kiʻekiʻe me ka mana o ʻoi aku ma mua o 500 watts. Ma keʻano laulā, pono e hoʻohana ʻia kēlā mau lasers no nā papa ma luna o 1mm. ʻO kāna mīkini wili he wili hohonu hohonu e pili ana i ka hopena o ka lua liʻiliʻi, me ka lakio hohonu-ākea nui, hiki ke piʻi aʻe ma mua o 5:1, wikiwiki ka wili ʻana, a me ka deformation thermal liʻiliʻi.

ʻO ke ʻano o ka mīkini hoʻoheheʻe laser hoʻomau 1000W 1500w 2000w

Nā Palena ʻenehana o ka Mīkini Kuʻi Laser Hoʻomau ʻo Fortune Laser

Nā mea komo

1. Kumu laser

2. Uea Laser Fiber

3. Poʻo kuʻihao laser QBH

4. 1.5P pahu hau

5. PC a me ka ʻōnaehana kuʻihao

6. 500 * 300 * 300 Linear Rail Servo Electric Translation Stage

7. ʻŌnaehana hoʻokele ʻehā-axis 3600

8. ʻŌnaehana kāmela CCD

9. Keʻena Mainframe