Kupambana kwa chitsulo ndikuwotcherera ndi laserzimatengera mphamvu zake zazikulu. Mwachitsanzo, kuwunikira kwambiri kumatha kuletsa mphamvu ya laser, pomwe kusinthasintha kwakukulu kwa kutentha kumachotsa kutentha mwachangu kwambiri kuchokera kudera la weld. Makhalidwe amenewa, pamodzi ndi malo osungunuka, amatsimikiza momwe chinthu chimayamwira mphamvu bwino kuti chipange weld yolimba komanso yolondola.

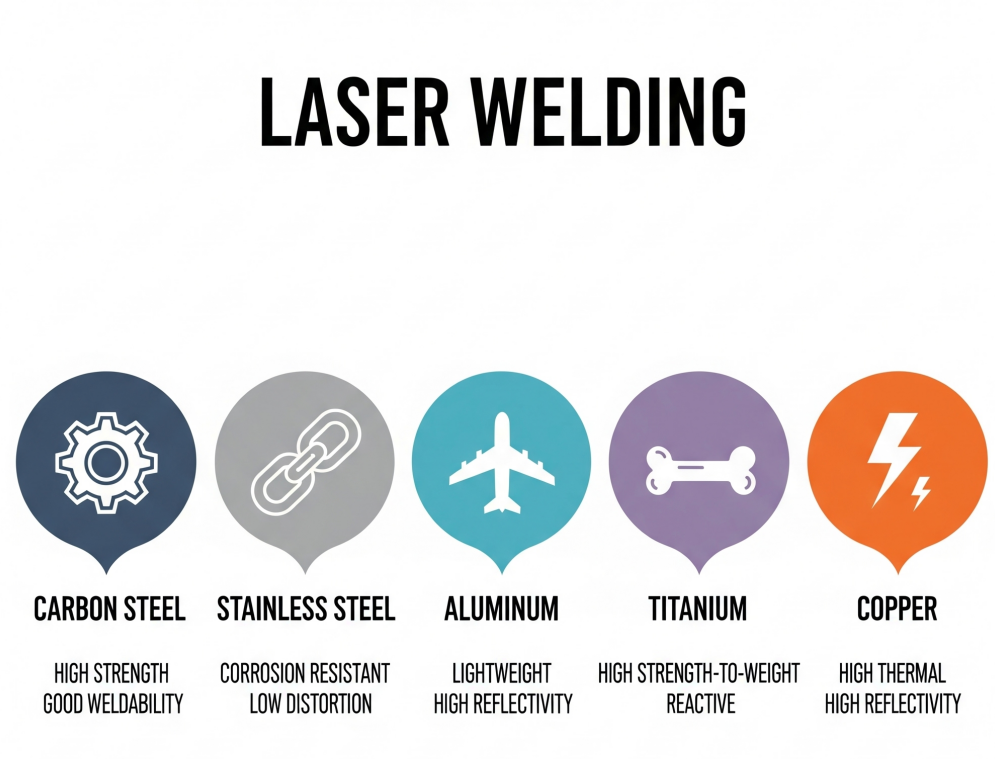

Apa pali kusanthula kwa zitsulo wamba ndi momwe zinthu zawo zimagwirira ntchito.

Kuwotcherera kwa Laser Chitsulo cha Carbon

Chitsulo cha kaboni ndi aloyi yachitsulo ndi kaboni yokhala ndi kaboni wokwana 2.1%. Kuchuluka kwa kaboni ndiye chinthu chachikulu chomwe chimatsimikizira mawonekedwe ake.

Chitsulo chopanda mpweya wambiri(yochepera 0.25% kaboni) ndi yofewa, yolimba, yosavuta kugwiritsa ntchito komanso yowongoleredwa. Nthawi zambiri imagwiritsidwa ntchito popanga mapanelo a thupi, waya, ndi mapaipi.

Chitsulo chapakati cha kaboni(0.25% mpaka 0.60% ya kaboni) ndi yolimba komanso yolimba kuposa chitsulo chopanda kaboni wambiri. Izi zimapangitsa kuti ikhale yoyenera pazinthu zomwe zimafuna mphamvu zambiri komanso kukana kuwonongeka, monga magiya, ma shaft, ndi mawilo a sitima.

Chitsulo cha kaboni wambiri(yoposa 0.60% kaboni) ndi yamphamvu komanso yolimba kwambiri mwa zitatuzi, komanso ndi yopepuka komanso yosalimba kwambiri. Kulimba kwake kumapangitsa kuti ikhale yoyenera kudula zida, masipiringi, ndi mawaya amphamvu kwambiri, koma imafunika kuisamalira mosamala powotcherera kuti isasweke.

Chitsulo cha kaboni ndi ntchito yovuta kwambiri popanga zinthu, ndipo zimafunika kuwotcherera bwino pogwiritsa ntchito laser.

Ubwino: Mumapeza ma weld amphamvu komanso ozama kwambiri komanso olondola kwambiri komanso osasokoneza kwambiri. Liwiro lake ndi labwino kwambiri, ndipo limawonjezera ntchito pafakitale.

Zoganizira: Kuziziritsa mwachangu kwa njira ya laser kungapangitse kuti chotenthetseracho chikhale chofooka komanso chosweka mosavuta. Nthawi zina, kutenthetsa gawolo pasadakhale ndikofunikira kuti kuziziritsa kuchedwetse ndikuletsa mavuto.

Kuwotcherera kwa Laser Chitsulo Chosapanga Dzira

Iyi ndi njira yofanana yopangidwira kumwamba. Kuwotcherera ndi laser ndi njira yabwino kwambiri yopangira zitsulo zosapanga dzimbiri, makamaka m'mafakitale omwe amafuna ukhondo.

Ubwino: Kutentha kochepa komanso kokhazikika ndi kupambana kwakukulu. Kumasunga mphamvu zosagwirizana ndi dzimbiri za chitsulo chosapanga dzimbiri mwa kupewa chinthu chotchedwa "carbide precipitation." Izi zimapangitsa kuti pakhale ma weld oyera komanso olondola opangidwa ndi opaleshoni, ndichifukwa chake ndi otchuka kwambiri m'mafakitale azachipatala ndi chakudya.

Zoganizira: Zitsulo zosapanga dzimbiri zodziwika bwino, monga 300 series (monga 304, 316), zimasungunulidwa bwino kwambiri. Komabe, mitundu ina, monga 400 series, imatha kusweka m'dera lomwe lakhudzidwa ndi kutentha.

Kuwotcherera kwa Laser Aluminiyamu

Kuwotcherera aluminiyamu kwakhala kovuta nthawi zonse, koma kuwotcherera ndi laser kukusintha masewerawa.

Ubwino: Aluminiyamu ndi chotenthetsera chabwino kwambiri, zomwe zikutanthauza kuti ndi kuwotcherera kwachikhalidwe, kutentha kumafalikira ndikupangitsa gawo lonselo kupindika. Mphamvu yolunjika ya laser ndi kutentha kochepa kumathetsa vutoli, kuchepetsa kwambiri kupotoka.

Zoganizira: Aluminiyamu imawala kwambiri. Malo owala amatha kugwedeza kuwala kwa laser nthawi yomweyo. Kupambana kumadalira zinthu zingapo zofunika: kuyeretsa malo bwino, mpweya woteteza bwino, komanso kugwiritsa ntchito mtundu woyenera wa laser (nthawi zambiri ma fiber laser ndi omwe amakondedwa) kuti atsimikizire kuti mphamvuyo yalowa.

Kuwotcherera kwa Laser Titanium

Ngati mukufuna kulumikiza titaniyamu, laser ndi imodzi mwa zida zanu zabwino kwambiri pantchitoyi.

UbwinoTitanium ndi chitsulo chosinthika, zomwe zikutanthauza kuti chimadetsedwa mosavuta ndi mpweya mumlengalenga chikasungunuka, zomwe zimapangitsa kuti chikhale chofewa komanso chophwanyika. Liwiro ndi kulondola kwa laser zimachepetsa nthawi yomwe chitsulocho chimasungunuka ndikuwonekera, zomwe zimachepetsa chiopsezo cha kuipitsidwa ndi kusweka.

ZoganiziraMonga momwe zilili ndi TIG welding titanium, muyenerabe kusamala kwambiri. Ukhondo weniweni komanso chitetezo chokwanira ndi mpweya wosagwira ntchito (monga argon) sizingatheke kukambirana.

Kuwetsa Mkuwa ndi Zitsulo Zina Zowunikira ndi Laser

Apa ndi pomwe kuwotcherera kwa laser kumakankhira malire a zomwe zingatheke.

Ubwino: Makina owotcherera a laser amatha kulumikiza zinthu zowala kwambiri monga mkuwa, zomwe zimakhala zovuta kwambiri kuzilumikiza ndi njira ina iliyonse. Izi ndizofunikira kwambiri pakugwiritsa ntchito mabatire amagetsi (EV), komwe mkuwa ndi aluminiyamu ziyenera kulumikizidwa.

ZoganiziraIzi ndi zinthu za akatswiri. Kuwunikira kwambiri komanso kutentha kumatha kuwononga kuwala kwa laser ngati sikuyendetsedwa bwino. Nthawi zambiri kumafuna zida zapadera, pamodzi ndi njira zapamwamba.

Kodi L ndi chiyani?kutsanzira laser welding?

Ngakhale zikumveka ngati chida chozizwitsa, sichabwino pa ntchito iliyonse. Ndikofunikira kumvetsetsa kusiyana kwake.

1.Mtengo Woyamba Wapamwamba: Makina ochapira a laser ndi ndalama zambiri, okwera mtengo kwambiri kuposa makina achikhalidwe a MIG kapena TIG.

2.Zofunikira Zolimba ZolumikizanaMonga tanenera, ma laser amafunika kukwanira bwino kwambiri. Ngati ziwalo zanu zili ndi mipata kapena sizinadulidwe bwino, laseryo singathe kuzilumikiza bwino.

3.Nkhani Zokhudza KuzindikiraZipangizo zowala monga aluminiyamu ndi mkuwa zingakhale zovuta kuzilumikiza popanda kugwiritsa ntchito laser ndi njira zapadera.

4.Nkhawa za Chitetezo: Kuwala kwa laser kwamphamvu kwambiri ndi koopsa kwambiri ndipo kungayambitse kuvulala kwakukulu kwa maso ndi kupsa kwa khungu, ngakhale kuchokera ku kuwala. Makoma oyenera achitetezo ndi zida zodzitetezera (PPE) ndizofunikira kwambiri.

Njira Zabwino Kwambiri Zogwiritsira Ntchito Ma Laser Welds Opanda Chilema

Kuti mugwiritse ntchito bwino njira yanu yowotcherera ndi laser, muyenera kutsatira mfundo zazikulu.

Kukonzekera ndi Chilichonse

Kulimbitsa Magulu OgwirizanaSitingathe kunena mokwanira: ziwalo zanu ziyenera kugwirizana bwino. Yesetsani kuti pakhale kusiyana kosakwana 10% ya makulidwe a chinthucho kuti mupeze zotsatira zabwino.

Kuyeretsa PamwambaChotsani chilichonse chomwe sichili chitsulo. Izi zikutanthauza kuchotsa mafuta onse, mafuta, ma oxide, ndi zina zilizonse zodetsa. Malo oyera ndi ofunikira kuti mupewe ma pores ndi zolakwika zina mu weld yanu.

Yang'anirani Njira Yanu

Mpweya WotetezaMonga momwe zilili ndi TIG ndi MIG, kuwotcherera pogwiritsa ntchito laser kumagwiritsa ntchito mpweya wopanda mphamvu (nthawi zambiri argon kapena helium) kuti uteteze dziwe losungunula la weld ku mpweya ndi nayitrogeni mumlengalenga, zomwe zimapangitsa kuti weld ikhale yolimba komanso yoyera.

Kukonza Ma Parameter: Muyenera kuyimba mu makonda anu. Mphamvu ya laser, liwiro la kuwotcherera, ndi mtunda wolunjika ziyenera kulinganizidwa bwino kuti zigwirizane ndi zinthu zomwe mukugwiritsa ntchito komanso makulidwe ake.

Chitetezo Choyamba, Nthawi Zonse

Kuwotcherera ndi laser si njira yomwe mungakhale osachitapo kanthu. Kuwala kolunjika ndi kwamphamvu kwambiri. Aliyense amene ali pafupi ndi opaleshoni ayenera kuvala magalasi apadera achitetezo a laser omwe amayesedwa malinga ndi kutalika kwa nthawi ya laser yanu.

Kodi Makina Ochapira a Laser Ndiwo Chisankho Chabwino Kwa Inu?

Kotero, kodi muyenera kuyika ndalama mu laser welding?

Tiyeni tikambirane mwachidule. Kuwotcherera kwa laser ndi chida chapamwamba chopangira chomwe chimapereka liwiro losayerekezeka, kulondola, komanso mtundu. Kusinthana ndi mtengo woyambira wapamwamba komanso zofunikira kwambiri pazida zoyera komanso zoyenera.

Lingaliro lathu lomalizaNgati ntchito yanu ikufuna mphamvu zambiri, makina odzipangira okha, komanso kulondola kwapadera—makamaka pa zipangizo zovuta kapena zovuta—ndiye kuti kuwotcherera ndi laser si njira ina chabe. Ndi njira yabwino kwambiri yomwe ingasinthe kwambiri kapangidwe kanu.

Nthawi yotumizira: Ogasiti-15-2025