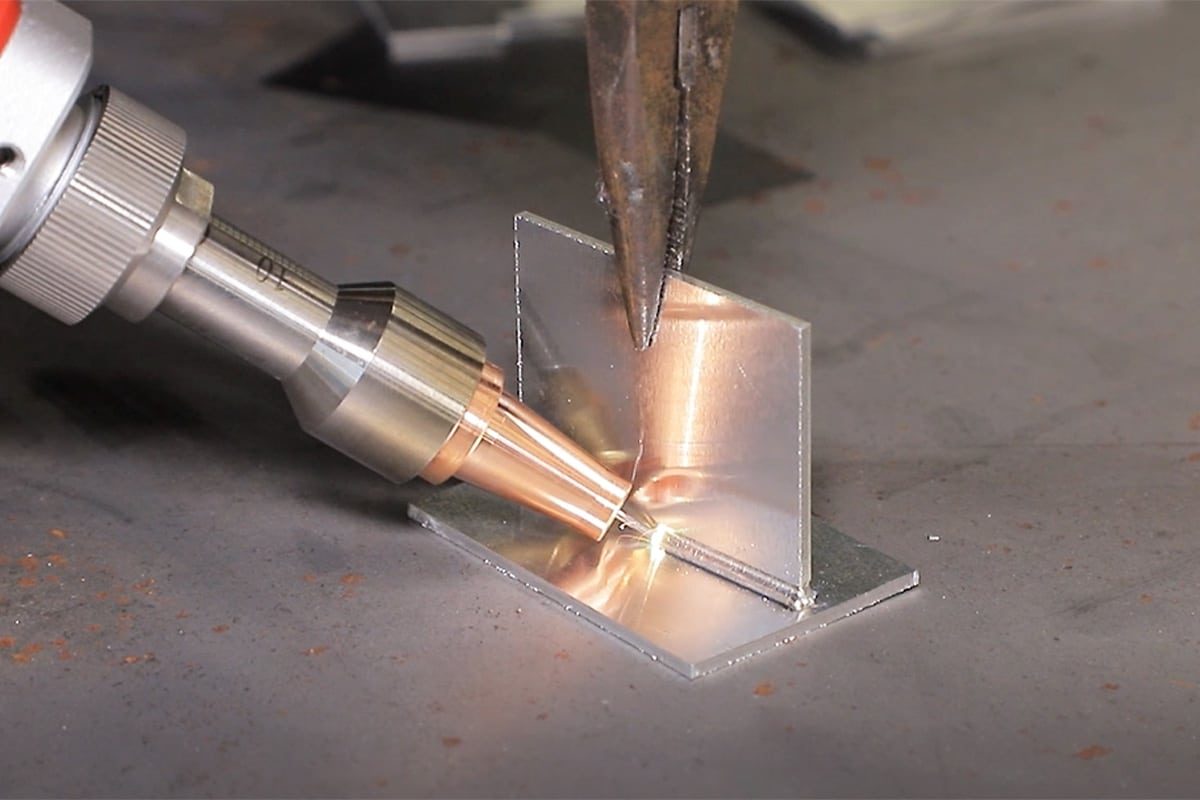

Kwa mainjiniya, opanga zinthu, ndi oyang'anira ntchito, vuto ndi losatha: momwe mungalumikizire zigawo zachitsulo chosapanga dzimbiri popanda kupindika, kusintha mtundu, komanso kuchepetsa kukana dzimbiri komwe kumayambitsa njira zachikhalidwe. Yankho ndi ili:kuwotcherera chitsulo chosapanga dzimbiri pogwiritsa ntchito laser, ukadaulo wosintha womwe umapereka liwiro, kulondola, komanso khalidwe losayerekezeka lomwe TIG ndi MIG welding yachikhalidwe sizingafanane nalo.

Kuwotcherera pogwiritsa ntchito laser kumagwiritsa ntchito kuwala kochuluka kwambiri kuti kusungunule ndi kusakaniza chitsulo chosapanga dzimbiri ndi kutentha kochepa komanso kolamulidwa. Njira yolondola imeneyi imathetsa mavuto akuluakulu a kutentha ndi kuchuluka kwa kuwotcherera.

Ubwino Waukulu wa Kuweta Chitsulo Chosapanga Dzimbiri ndi Laser:

-

Liwiro Lapadera:Imagwira ntchito mofulumira kwambiri kuposa TIG welding nthawi 4 mpaka 10, zomwe zimapangitsa kuti ntchito ikule bwino komanso kuti igwire bwino ntchito.

-

Kusokonezeka Kochepa:Kutentha kokhazikika kumapanga malo ochepa kwambiri okhudzidwa ndi kutentha (HAZ), omwe amachepetsa kwambiri kapena kuthetsa kupindika, ndikusunga kulondola kwa gawolo.

-

Ubwino Wapamwamba:Amapanga ma weld oyera, olimba, komanso okongola omwe safuna kuphwanyidwa kapena kumalizidwa pambuyo pa weld.

-

Zinthu Zosungidwa:Kutentha kochepa kumasunga mphamvu ya chitsulo chosapanga dzimbiri komanso kukana dzimbiri, zomwe zimathandiza kupewa mavuto monga "kuwola kwa weld".

Bukuli limapereka chidziwitso chaukadaulo chofunikira kuti musinthe kuchoka pa kumvetsetsa koyambira kupita ku kugwiritsa ntchito modalirika, ndikuwonetsetsa kuti mutha kugwiritsa ntchito bwino luso lonse la njira yapamwambayi yopangira zinthu.

Kuwotcherera kwa Laservs. Njira Zachikhalidwe: Kuyerekeza Molunjika

Kusankha njira yoyenera yowotcherera ndikofunikira kwambiri kuti polojekitiyi ipambane. Umu ndi momwe kuwotcherera kwa laser kumagwirizanirana ndi TIG ndi MIG pakugwiritsa ntchito chitsulo chosapanga dzimbiri.

Kuwetsa kwa Laser vs. Kuwetsa kwa TIG

Kuwotcherera kwa Tungsten Inert Gas (TIG) kumadziwika ndi mawotcherera apamwamba komanso opangidwa ndi manja koma kumavuta kupitilizabe kugwira ntchito bwino popanga zinthu.

-

Liwiro ndi Kubereka:Kuwotcherera kwa laser kumachitika mwachangu kwambiri, zomwe zimapangitsa kuti ikhale chisankho chomveka bwino chopangira zinthu zokha komanso zokwera mtengo.

-

Kutentha ndi Kupotoza:Chitsulo cha TIG ndi gwero losagwira ntchito bwino komanso losayatsa kutentha lomwe limapanga HAZ yayikulu, zomwe zimapangitsa kuti pakhale kusokonekera kwakukulu, makamaka pa chitsulo chopyapyala. Kuwala kolunjika kwa laser kumaletsa kuwonongeka kwa kutentha kumeneku.

-

Zokha zokha:Makina a laser ndi osavuta kupanga okha, zomwe zimathandiza kupanga zinthu zambiri komanso mobwerezabwereza popanda luso lofunikira kwambiri pamanja kuposa TIG.

Kuwetsa kwa Laser vs. MIG

Kuwotcherera kwa Metal Inert Gas (MIG) ndi njira yosinthasintha komanso yotsika mtengo, koma siili ndi kulondola kwa laser.

-

Kulondola ndi Ubwino:Kuwotcherera pogwiritsa ntchito laser ndi njira yosakhudzana ndi zinthu zomwe zimapangitsa kuti ma weld akhale oyera komanso opanda madontho. Kuwotcherera pogwiritsa ntchito MIG kumakhala ndi madontho omwe amafunika kutsukidwa pambuyo pa kuwotcherera.

-

Kulekerera Kusiyana:Kuwotcherera kwa MIG kumathandiza kwambiri ngati malo olumikizirana sakugwirizana bwino chifukwa waya wake wogwiritsidwa ntchito umagwira ntchito ngati chodzaza. Kuwotcherera kwa laser kumafuna kulumikizidwa bwino komanso kulekerera bwino.

-

Kukhuthala kwa Zinthu:Ngakhale kuti ma laser amphamvu kwambiri amatha kugwira ntchito ndi zigawo zokhuthala, MIG nthawi zambiri imakhala yothandiza kwambiri pa mbale yolemera kwambiri. Kuwotcherera kwa laser kumapambana kwambiri pa makulidwe a zinthu zopyapyala mpaka zapakati pomwe kuwongolera kupotoza ndikofunikira kwambiri.

Tebulo Loyerekeza Pang'onopang'ono

| Mbali | Kuwotcherera kwa Laser Beam | Kuwotcherera kwa TIG | Kuwotcherera kwa MIG |

| Kuwotcherera Liwiro | Kwambiri Kwambiri (4-10x TIG)

| Zochepa Kwambiri | Pamwamba |

| Malo Okhudzidwa ndi Kutentha (HAZ) | Zochepa / Zopapatiza Kwambiri | Lalikulu | Lalikulu |

| Kusokonezeka kwa kutentha | Zosafunika | Pamwamba | Pakati mpaka Pamwamba |

| Kulekerera Kusiyana | Yotsika Kwambiri (<0.1 mm) | Pamwamba | Wocheperako |

| Mbiri Yowotcherera | Yopapatiza & Yakuya | Wotakata & Wosaya | Yotakata & Yosinthasintha |

| Mtengo Woyamba wa Zipangizo | Pamwamba Kwambiri | Zochepa

| Wotsika mpaka Wocheperako

|

| Zabwino Kwambiri | Kulondola, liwiro, zochita zokha, zipangizo zoonda

| Ntchito yamanja yapamwamba kwambiri, kukongola

| Kupanga zinthu zambiri, zipangizo zokhuthala |

Sayansi Yomwe Imayambitsa Kusungunula: Mfundo Zazikulu Zafotokozedwa

Kumvetsetsa momwe laser imagwirira ntchito ndi chitsulo chosapanga dzimbiri ndikofunikira kwambiri kuti mumvetse bwino njirayi. Imagwira ntchito makamaka m'njira ziwiri zosiyana zomwe zimatsimikiziridwa ndi kuchuluka kwa mphamvu.

Njira Yoyendetsera Mphamvu vs. Njira ya Keyhole

-

Kuwotcherera kwa Conduction:Pakakhala mphamvu zochepa, laser imatenthetsa pamwamba pa chinthucho, ndipo kutentha "kumayendetsa" mbaliyo. Izi zimapangitsa kuti pakhale weld yosaya, yayikulu, komanso yosalala bwino, yoyenera zipangizo zopyapyala (zosakwana 1-2 mm) kapena zooneka bwino pomwe mawonekedwe ake ndi ofunika kwambiri.

-

Kuwotcherera kwa Keyboo (Kulowa Kwambiri):Pa mphamvu zambiri (pafupifupi 1.5 MW/cm²), laser imatentha chitsulocho nthawi yomweyo, ndikupanga dzenje lozama komanso lopapatiza lotchedwa "keyboo." Keyboo iyi imasunga mphamvu ya laser, ndikuyilowetsa mkati mwa zinthuzo kuti zilowetsedwe mwamphamvu komanso mokwanira m'magawo okhuthala.

Mafunde Osalekeza (CW) vs. Ma Laser Opunduka

-

Mafunde Osalekeza (CW):Laser imapereka mphamvu yokhazikika komanso yosalekeza. Njira iyi ndi yoyenera kupanga mipata yayitali komanso yopitilira pa liwiro lalikulu popanga zinthu zokha.

-

Laser Yopukutidwa:Laser imapereka mphamvu mwachangu komanso mwamphamvu. Njira imeneyi imapereka ulamuliro wolondola pa kutentha komwe kumabwera, kuchepetsa HAZ ndikupangitsa kuti ikhale yoyenera kuwotcherera zinthu zofewa komanso zosapsa mtima ndi kutentha kapena kupanga ma weld olumikizana kuti agwirizane bwino.

Buku Lotsogolera Gawo ndi Gawo Lokonzekera Mopanda Chilema

Pakuwotcherera ndi laser, kupambana kumadziwika kuti mtandawo usanayambe kugwira ntchito. Kulondola kwa njirayi kumafuna kukonzekera mosamala.

Gawo 1: Kupanga ndi Kukonza Ma Joint

Mosiyana ndi kuwotcherera kwa arc, kuwotcherera kwa laser kumakhala kotsika kwambiri ngati pali mipata kapena kusakhazikika bwino.

-

Mitundu ya Ma Joint:Malungo olumikizira matako ndi omwe amagwira ntchito bwino kwambiri koma amafunika mpata wochepera zero (nthawi zambiri amakhala ochepera 0.1 mm pazigawo zoonda). Malungo olumikizira matako amakhala omasuka kwambiri pakusintha kwa malungo.

-

Kuwongolera Mipata:Mpata wochuluka udzaletsa dziwe laling'ono losungunuka kuti lisalumikizane ndi cholumikiziracho, zomwe zimapangitsa kuti chisakanizocho chisagwirizane bwino komanso kuti chikhale chofooka. Gwiritsani ntchito njira zodulira mwanzeru komanso zolimba kuti muwonetsetse kuti chikugwirizana bwino.

Gawo Lachiwiri: Kuyeretsa Malo ndi Kuchotsa Zodetsa

Mphamvu yamphamvu ya laser imachotsa zinthu zilizonse zodetsa pamwamba, kuzigwira mu weld ndikuyambitsa zolakwika monga ma pores.

-

Ukhondo ndi Wofunika Kwambiri:Pamwamba pake payenera kukhala popanda mafuta, mafuta, fumbi, ndi zotsalira za zomatira.

-

Njira Yoyeretsera:Pukutani malo olumikizirana ndi nsalu yopanda ulusi wothira mu chosungunulira chofewa monga acetone kapena 99% isopropyl alcohol musanawotchere.

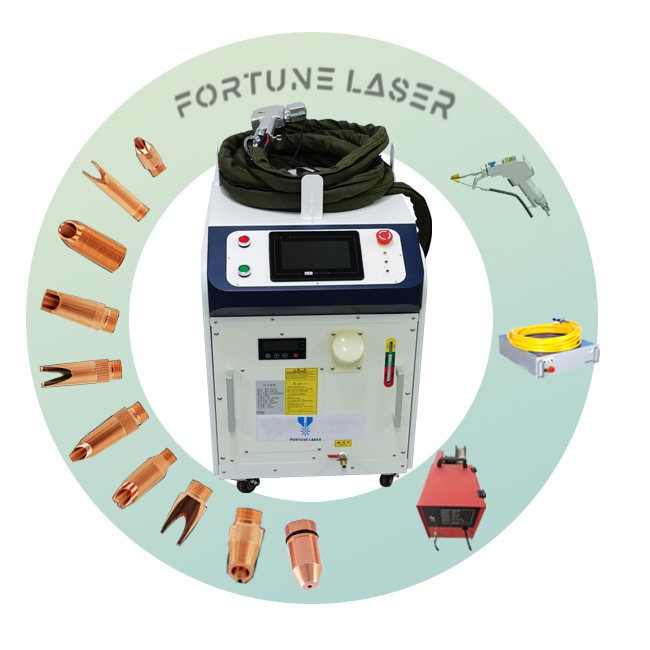

Kudziwa Makina: Kukonza Magawo Ofunika Othandizira Kuwotcherera

Kuti mupeze weld yabwino kwambiri pamafunika kulinganiza zinthu zingapo zolumikizana.

Parameter Triad: Mphamvu, Liwiro, ndi Malo Oyang'anira

Makonzedwe atatuwa pamodzi amatsimikizira momwe mphamvu imalowera ndi momwe zimagwirira ntchito.

-

Mphamvu ya Laser (W):Mphamvu yokwera imalola kulowa mozama komanso kuthamanga mwachangu. Komabe, mphamvu yochulukirapo ingayambitse kupsa kwa zinthu zoonda.

-

Liwiro la Kuwotcherera (mm/s):Kuthamanga mofulumira kumachepetsa kutentha komwe kumalowetsa ndi kusokoneza. Ngati liwiro lili lalikulu kwambiri kuposa mphamvu, lingayambitse kulowa kosakwanira.

-

Malo Oyang'ana:Izi zimasintha kukula kwa malo a laser ndi kuchuluka kwa mphamvu. Kuyang'ana pamwamba kumapanga weld yozama kwambiri komanso yopapatiza. Kuyang'ana pamwamba (positive defocus) kumapanga weld yokongola yotakata komanso yosaya kwambiri. Kuyang'ana pansi pa pamwamba (negative defocus) kungathandize kuti zinthu zokhuthala zilowe bwino.

Kusankha Mpweya Woteteza: Argon vs. Nayitrogeni

Mpweya woteteza umateteza dziwe losungunuka la weld ku kuipitsidwa ndi mlengalenga ndipo umalimbitsa ntchitoyi.

-

Argon (Ar):Chisankho chofala kwambiri, chomwe chimapereka chitetezo chabwino kwambiri komanso kupanga ma welds okhazikika komanso oyera.

-

Nayitrogeni (N2):Kawirikawiri amakondedwa ndi chitsulo chosapanga dzimbiri, chifukwa chingathandize kuti cholumikizira chomaliza chisagwe ndi dzimbiri.

-

Kuchuluka kwa Mayendedwe:Kuthamanga kwa madzi kuyenera kukonzedwa bwino. Kuchepa kwambiri sikungateteze chotchingira madzi, pomwe kuchuluka kwambiri kungayambitse kugwedezeka ndikukopa zinthu zodetsa. Kuthamanga kwa madzi kwa malita 10 mpaka 25 pamphindi (L/min) ndi komwe kumayambira.

Mfundo Zoyambira za Parameter: Tebulo Lofotokozera

Izi ndi malo oyambira kuwotcherera chitsulo chosapanga dzimbiri cha 304/316 austenitic. Nthawi zonse yesani zinthu zotsala kuti mukonze bwino ntchito yanu.

| Kukhuthala kwa Zinthu (mm) | Mphamvu ya Laser (W) | Liwiro la kuwotcherera (mm/s) | Malo Oyang'ana Kwambiri | Mpweya Woteteza |

| 0.5 | 350 - 500 | 80 - 150 | Pamwamba | Argon kapena Nayitrogeni |

| 1.0 | 500 – 800 | 50 - 100 | Pamwamba | Argon kapena Nayitrogeni |

| 2.0 | 800 – 1500 | 25 - 60 | Pansi pang'ono pa nthaka | Argon kapena Nayitrogeni |

| 3.0 | 1500 - 2000 | 20 - 50 | Pansi pa nthaka | Argon kapena Nayitrogeni |

| 5.0 | 2000 - 3000 | 15 - 35 | Pansi pa nthaka | Argon kapena Nayitrogeni |

Kuwongolera Ubwino: Buku Lothandizira Kuthetsa Mavuto a Zovuta Zofala

Ngakhale mutachita zinthu molondola, zolakwika zimatha kuchitika. Kumvetsa chomwe chimayambitsa vutoli ndiye chinsinsi chopewera.

Kuzindikira Zolakwika Zodziwika Bwino Zogwiritsa Ntchito Laser

-

Kuyenda pang'onopang'ono:Ma thovu ang'onoang'ono a mpweya omwe amatsekeredwa mu weld, nthawi zambiri amayamba chifukwa cha kuipitsidwa pamwamba kapena kutuluka kwa mpweya kosayenera.

-

Kutentha Kwambiri:Ming'alu yapakati yomwe imapanga pamene cholumikizira chikulimba, nthawi zina chifukwa cha kapangidwe ka zinthu kapena kutentha kwambiri.

-

Kulowa Kosakwanira:Cholukiziracho chimalephera kulumikiza mozama monse, nthawi zambiri chifukwa cha mphamvu yosakwanira kapena liwiro lopitirira muyeso.

-

Kudula pang'ono:Mzere wosungunuka mu chitsulo choyambira m'mphepete mwa chosungunula, nthawi zambiri umachitika chifukwa cha liwiro lalikulu kapena mpata waukulu.

-

Kutulutsa:Madontho osungunuka omwe amatuluka mu dziwe losungunula, nthawi zambiri chifukwa cha kuchuluka kwa mphamvu kapena kuipitsidwa pamwamba.

Tchati Chothetsera Mavuto: Zoyambitsa ndi Mayankho

| Chilema | Zifukwa Zomwe Zingachitike | Zochita Zoyenera Kukonza |

| Kuyenda pang'onopang'ono | Kuipitsidwa pamwamba; mpweya woipa wotuluka m'thupi. | Yesetsani kuyeretsa bwino musanagwiritse ntchito weld; onetsetsani kuti mpweya ndi wabwino komanso kuti muwonjezere kuchuluka kwa madzi omwe akuyenda. |

| Kutentha Kwambiri | Zinthu zomwe zimakhudzidwa; kutentha kwambiri. | Gwiritsani ntchito waya woyenera wodzaza; tenthetsani zinthuzo kuti muchepetse kutentha. |

| Kulowa Kosakwanira | Mphamvu yosakwanira; liwiro lopitirira muyeso; kusayang'ana bwino. | Wonjezerani mphamvu ya laser kapena chepetsani liwiro la kuwotcherera; tsimikizirani ndikusintha malo olunjika. |

| Kudula pang'ono | Liwiro lopitirira muyeso; mpata waukulu wa malo olumikizirana. | Chepetsani liwiro la kuwotcherera; konzani momwe zinthu zilili kuti muchepetse kusiyana kwa malo. |

| Kutulutsa madzi | Kuchuluka kwa mphamvu; kuipitsidwa pamwamba. | Chepetsani mphamvu ya laser kapena gwiritsani ntchito njira yochepetsera kuwala; onetsetsani kuti malo ake ndi oyera bwino. |

Masitepe Omaliza: Kuyeretsa Pambuyo pa Kusenda ndi Kuchepetsa Kutopa

Njira yowotcherera imawononga zinthu zomwe zimapangitsa chitsulo chosapanga dzimbiri kukhala "chopanda dzimbiri." Kuchibwezeretsa ndi gawo lomaliza lofunikira.

Chifukwa Chake Simungathe Kudumpha Chithandizo Pambuyo pa Kusungunula

Kutentha kochokera ku kuwotcherera kumawononga wosanjikiza wosawoneka bwino wa chromium-oxide pamwamba pa chitsulocho. Izi zimapangitsa kuti chowotchereracho ndi HAZ yozungulira zikhale pachiwopsezo cha dzimbiri ndi dzimbiri.

Njira Zosinthira Zinthu Mwachisawawa Zafotokozedwa

Passivation ndi mankhwala omwe amachotsa zodetsa pamwamba ndipo amathandiza kusintha chromium-oxide layer yolimba komanso yofanana.

-

Kusankha Mankhwala:Njira yachikhalidwe yogwiritsira ntchito ma asidi oopsa monga nitric ndi hydrofluoric acid kuyeretsa ndi kupumitsa pamwamba.

-

Kuyeretsa kwa Ma Electrochemical:Njira yamakono, yotetezeka, komanso yachangu yomwe imagwiritsa ntchito madzi ofooka a electrolytic ndi mphamvu yamagetsi yochepa kuti iyeretse ndikuchepetsa weld pang'onopang'ono.

Chitetezo Choyamba: Zofunikira Zosamala Pakuwotcherera ndi Laser

Kuwotcherera kwa laser pogwiritsa ntchito mphamvu zambiri kumabweretsa zoopsa zazikulu pantchito zomwe zimafuna njira zodzitetezera zolimba.

Ngozi Yobisika: Utsi wa Hexavalent Chromium (Cr(VI))

Chitsulo chosapanga dzimbiri chikatenthedwa kutentha kwa welding, chromium yomwe ili mu alloy imatha kupanga hexavalent chromium (Cr(VI)), yomwe imauluka mu utsi.

-

Zoopsa pa Thanzi:Cr(VI) ndi khansa yodziwika bwino yomwe imayambitsa khansa ya m'mapapo mwa anthu. Ingayambitsenso kukwiya kwambiri m'mapapo, m'khungu, komanso m'maso.

-

Malire Okhudzana ndi Kuwonekera:OSHA imakhazikitsa malire okhwima a Permissible Exposure Limit (PEL) a 5 micrograms pa mita imodzi ya mpweya (5 µg/m³) ya Cr(VI).

Njira Zofunika Zotetezera

-

Zowongolera Zauinjiniya:Njira yothandiza kwambiri yotetezera antchito ndiyo kuzindikira ngoziyo komwe imachokera.njira yochotsera utsiNdi fyuluta ya HEPA yokhala ndi magawo ambiri, ndikofunikira kuti tigwire tinthu tating'onoting'ono tomwe timapangidwa ndi laser welding.

-

Zipangizo Zodzitetezera Payekha (PPE):Ogwira ntchito onse m'derali ayenera kuvala magalasi oteteza a laser omwe ali ndi mafunde ofanana ndi a laser. Ngati kuchotsa utsi sikungachepetse kukhudzana ndi PEL, ma respiratory ovomerezeka amafunika. Ntchito yowotcherera iyeneranso kuchitika mkati mwa malo otetezedwa ndi kuwala okhala ndi maloko otetezera kuti asawonekere mwangozi.

Mafunso Ofunsidwa Kawirikawiri (Mafunso Ofunsidwa Kawirikawiri)

Kodi mtundu wa laser wabwino kwambiri wowotcherera chitsulo chosapanga dzimbiri ndi uti?

Ma laser a fiber nthawi zambiri amakhala chisankho chabwino kwambiri chifukwa cha kutalika kwa nthawi yawo, komwe kumayamwa mosavuta ndi chitsulo chosapanga dzimbiri, komanso khalidwe lawo labwino kwambiri la kuwala kuti liziwongolera molondola.

Kodi mungathe kulumikiza chitsulo chosapanga dzimbiri ndi laser makulidwe osiyanasiyana?

Inde, kuwotcherera pogwiritsa ntchito laser kumathandiza kwambiri polumikiza makulidwe osiyanasiyana popanda kupotoza kwambiri komanso popanda kuwotcha mbali yopyapyala, ntchito yovuta kwambiri ndi kuwotcherera pogwiritsa ntchito TIG.

Kodi waya wodzaza ndi wofunikira pakuwotcherera chitsulo chosapanga dzimbiri pogwiritsa ntchito laser?

Kawirikawiri, ayi. Kuwotcherera kwa laser kumatha kupanga ma weld amphamvu, olowa mkati popanda zinthu zodzaza (autogenously), zomwe zimapangitsa kuti ntchitoyi ikhale yosavuta. Waya wodzaza umagwiritsidwa ntchito pamene kapangidwe ka cholumikizira kali ndi mpata waukulu kapena pamene pakufunika zinthu zinazake zachitsulo.

Kodi makulidwe apamwamba kwambiri a chitsulo chosapanga dzimbiri chomwe chingalumikizidwe ndi laser ndi otani?

Ndi makina amphamvu kwambiri, n'zotheka kulumikiza chitsulo chosapanga dzimbiri mpaka 1/4″ (6mm) kapena chokhuthala kwambiri pakadutsa kamodzi. Njira zosakanikirana za laser-arc zimatha kulumikiza zigawo zopitirira inchi imodzi.

Mapeto

Ubwino wa laser welding mu liwiro, kulondola, komanso khalidwe lake zimapangitsa kuti ikhale chisankho chabwino kwambiri pakupanga chitsulo chosapanga dzimbiri chamakono. Imapanga malo olimba komanso oyera okhala ndi kupotoka pang'ono, kusunga umphumphu ndi mawonekedwe a chinthucho.

Komabe, kupeza zotsatira zapamwamba izi kumadalira njira yonse. Kupambana ndiko kutha kwa unyolo wopanga zinthu molondola kwambiri—kuyambira kukonzekera bwino kwambiri komanso kuwongolera zinthu mwadongosolo mpaka kukakamizidwa pambuyo pa weld komanso kudzipereka kosalekeza ku chitetezo. Mukadziwa bwino njirayi, mutha kutsegula mulingo watsopano wa magwiridwe antchito ndi khalidwe labwino pantchito zanu.

Nthawi yotumizira: Okutobala-08-2025