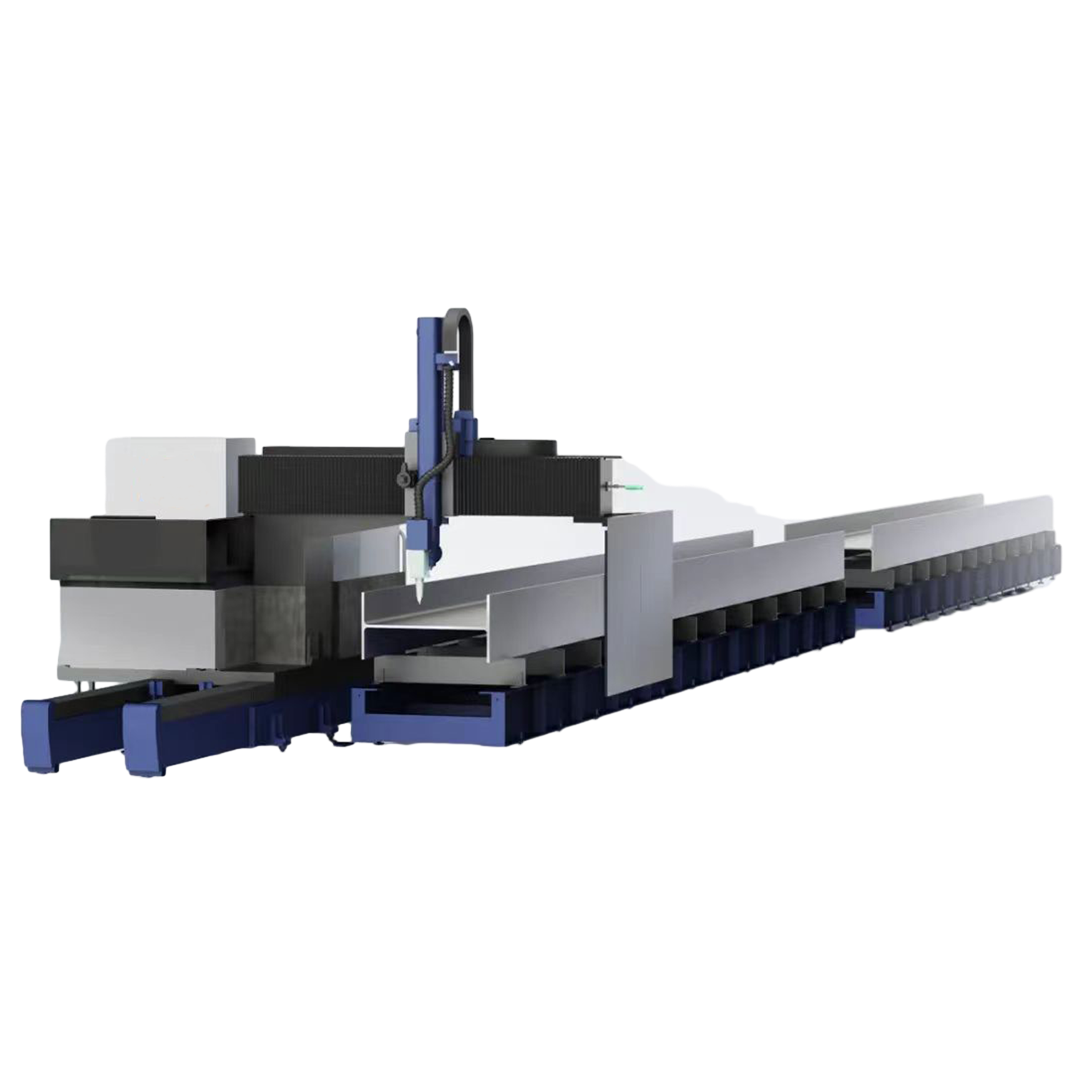

Makina Odulira a Laser a Fortune Laser Professional CNC 3D 5-Axis H Beam Laser

Makina Odulira a Laser a Fortune Laser Professional CNC 3D 5-Axis H Beam Laser

Zizindikiro za Makina

Makina odulira zitsulo a H okwana 12m/24m akuluakulu a H chitsulo/flat plate/bevel amagwiritsa ntchito njira ya German Beckhoff yokhala ndi magawo atatu a axis asanu. Mzere wopanga laser wa magawo atatu mu chimodzi ndi chinthu chaukadaulo chapamwamba chomwe chimaphatikiza ukadaulo wa RTCP CNC wa magawo atatu a axis asanu, kudula laser, makina olondola, ndi ukadaulo wozindikira wanzeru. Pankhani yokonza kapangidwe ka chitsulo, njira zachikhalidwe zoyendetsera ntchito, kudula malawi, kudula plasma, ndi njira zokweza ndi kutsitsa zinthu zodziyimira zokha zimagwiritsidwabe ntchito kuti ziwongolere ubwino ndi kupanga bwino kwa zinthu zopangira kapangidwe ka chitsulo ndikuchepetsa ndalama zogwirira ntchito.

Mzere wopanga wa laser wa atatu mu umodzi uli ndi kusinthasintha kwamphamvu ndipo ukhoza kusinthidwa. Umagwiritsidwa ntchito kwambiri m'mafakitale opanga zida zaukadaulo monga zomangamanga zachitsulo, zombo, makina aukadaulo, makina azolimo, mphamvu ya mphepo, mafuta, makampani opanga mankhwala, ndi uinjiniya wakunja. Umagwiritsidwa ntchito kwambiri popanga chitsulo chooneka ngati H, mafakitale odula chitsulo chooneka ngati C, chitsulo chooneka ngati sikweya, chitsulo chopindika, chitsulo cham'mbali, ndi zina zotero.

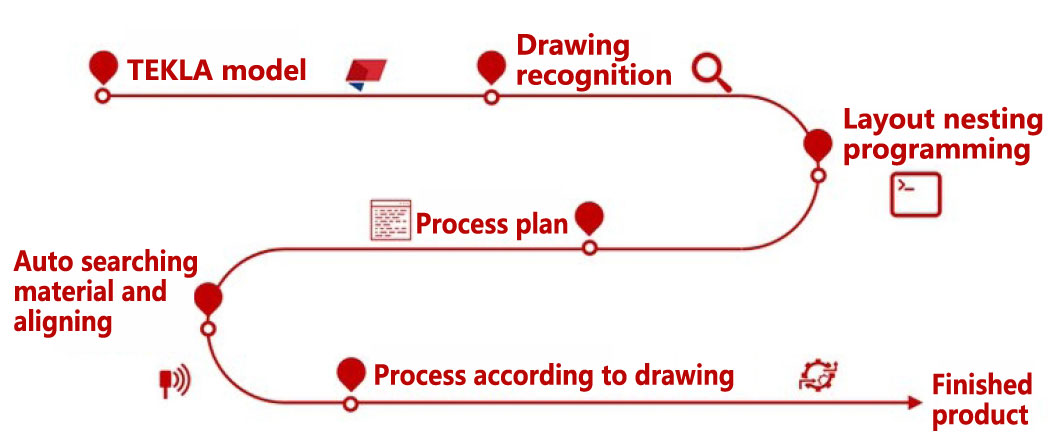

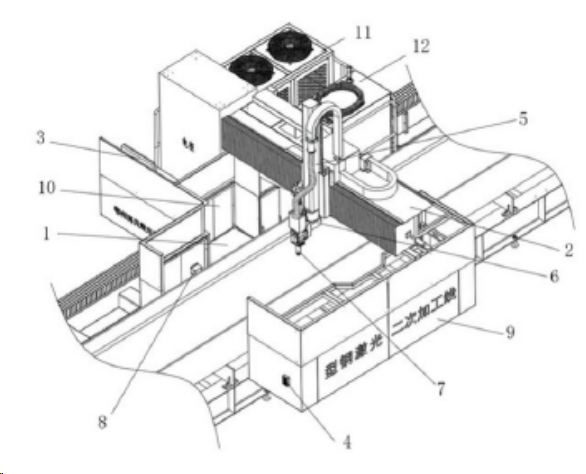

Kasinthidwe ka makina

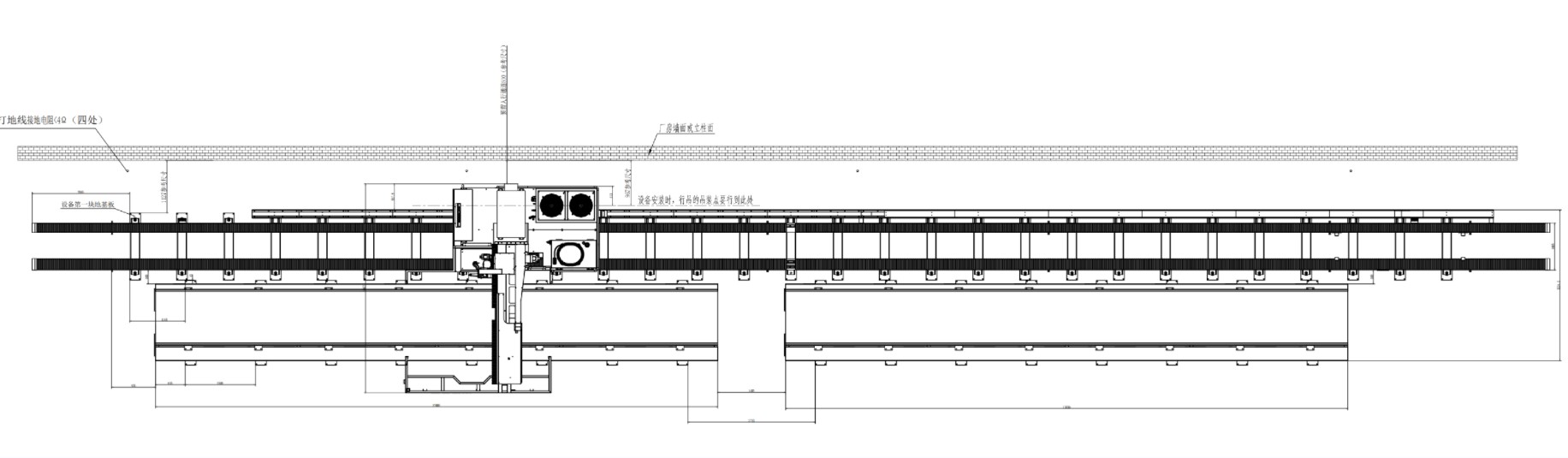

Kapangidwe ka ndondomeko ndi kayendedwe ka ntchito

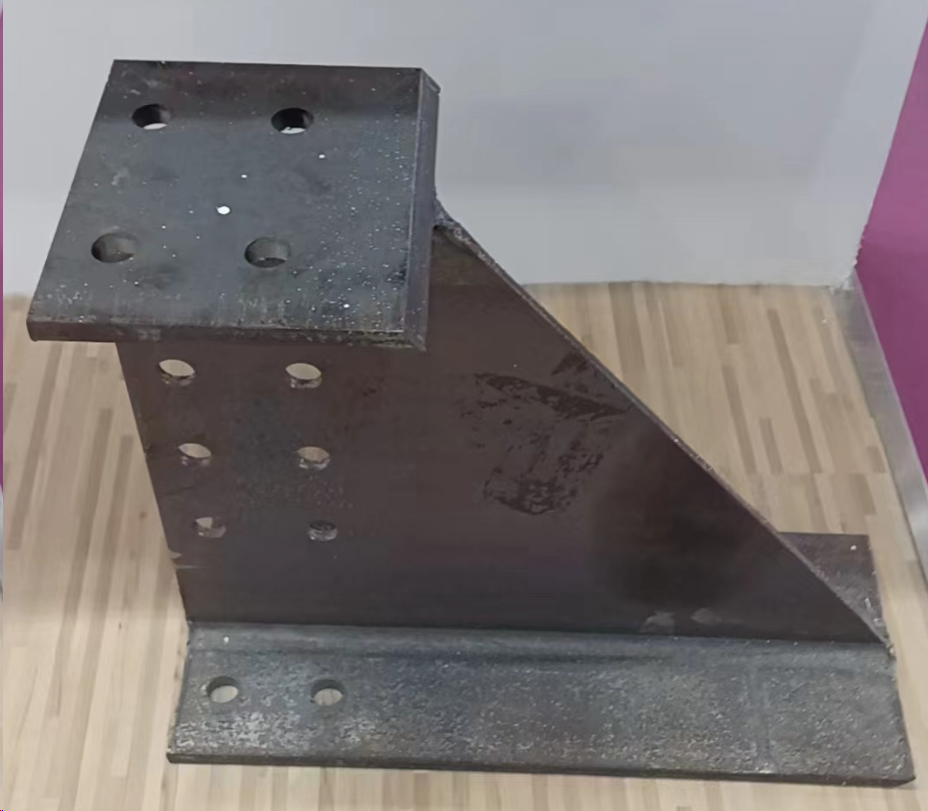

Mbali za Makina

1. Nsanja yosuntha

2. Chimango cha cantilever

3. Malo olamulira

4. Wolamulira wakutali

5. Z axis

6. Mzere wa AC

7. Kudula mutu

8. Sensa ya laser

9. Chivundikiro choteteza

10. Chishango cha Graphite

11. Choziziritsira madzi

12. Mphamvu ya laser

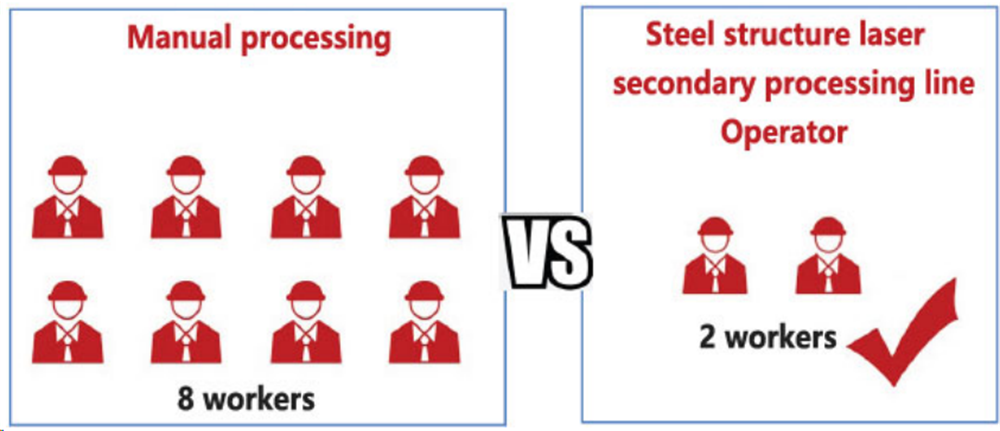

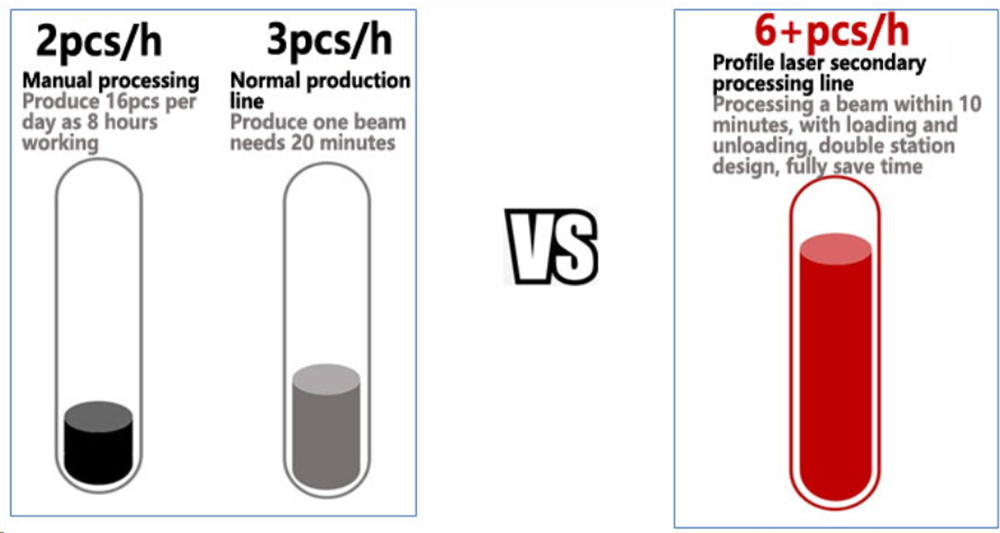

Poyerekeza ndi njira zachikhalidwe zopangira pamanja

Ma Multi-module CW Fiber Lasers opangidwa ndi Raycus ali ndi mphamvu zambiri zosinthira ma electro-optical, kuwala kwamphamvu kwambiri, mphamvu zambiri, ma modulation frequency ambiri, kudalirika kwambiri, moyo wautali, ntchito yopanda kukonza komanso zabwino zake. Chogulitsachi chingagwiritsidwe ntchito kwambiri pakuwotcherera, kudula molondola, kusungunula ndi kuvala, kukonza pamwamba, 3Dprinting ndi zina. Kugwira ntchito kwake kotulutsa kuwala kumathandiza kuti chigwirizane bwino ndi maloboti ngati zida zopangira zosinthika kuti zikwaniritse zofunikira pakukonza kwa 3D.

Makhalidwe a malonda:

➣ Mphamvu yosinthira ma electro-optical kwambiri

➣ Kutalika kwa ulusi wotulutsa kumatha kusinthidwa

➣ cholumikizira cha QD

➣ ntchito yopanda kukonza

➣ Kusinthasintha kwa ma frequency ambiri

➣ mphamvu yolimbana ndi kuthamanga kwa magazi

➣ Kudula mapepala bwino

Zambiri zaukadaulo za chipangizo cha laser:

| Dzina | Mtundu | Chizindikiro |

| Chipangizo cha laser (Raycus 12000W fiber laser) | Kutalika kwa mafunde | 1080±5nm |

| Zotuluka zovotera | 12000W | |

| Ubwino wa kuwala (BPP) | 2-3 (75μm)/3-3.5(100μm) | |

| Njira yogwirira ntchito ya laser | Kusintha kosalekeza | |

| Njira yozizira | Kuziziritsa madzi | |

| Kudula kwakukulu (Mukadula mbale yokhuthala, chifukwa cha zinthu ndi zifukwa zina, ma burrs amatha kuchitika) | CS: ≤30mmSS: ≤30mm |

Gwero la mphamvu la laser (Njira 2)

Ma Multi-module CW Fiber Lasers opangidwa ndi Raycus amayambira pa 3,000W mpaka 30kW, okhala ndi mphamvu zambiri zosinthira ma electro-optical, kuwala kwamphamvu kwambiri, mphamvu zambiri, ma modulation frequency ambiri, kudalirika kwambiri, moyo wautali wautumiki, ntchito yopanda kukonza komanso zabwino zake. Chogulitsachi chingagwiritsidwe ntchito kwambiri pakuwotcherera, kudula molondola, kusungunula ndi kuvala, kukonza pamwamba, 3Dprinting ndi zina. Kugwira ntchito kwake kotulutsa kuwala kumathandizira kuti chigwirizane bwino ndi maloboti ngati zida zopangira zosinthika kuti zikwaniritse zofunikira pakukonza kwa 3D.

Makhalidwe a malonda:

➣ Mphamvu yosinthira ma electro-optical kwambiri

➣ Kutalika kwa ulusi wotulutsa kumatha kusinthidwa

➣ cholumikizira cha QD

➣ ntchito yopanda kukonza

➣ Kusinthasintha kwa ma frequency ambiri

➣ mphamvu yolimbana ndi kuthamanga kwa magazi

➣ Kudula mapepala bwino

Zambiri zaukadaulo za chipangizo cha laser:

| Dzina | Mtundu | Chizindikiro |

| Chipangizo cha laser (Raycus 20000W fiber laser) | Kutalika kwa mafunde | 1080±5nm |

| Zotuluka zovotera | 20000W/30000W | |

| Ubwino wa kuwala (BPP) | 2-3 (75μm)/3-3.5(100μm) | |

| Njira yogwirira ntchito ya laser | Kusintha kosalekeza | |

| Njira yozizira | Kuziziritsa madzi | |

| Kudula kwakukulu (Mukadula mbale yokhuthala, chifukwa cha zinthu ndi zifukwa zina, ma burrs amatha kuchitika) | CS: ≤50mmSS: ≤40mm |

Mapulogalamu owongolera ndi mapulogalamu omangira zisa

Makina ogwiritsira ntchito a CNC amagwiritsa ntchito njira yachiwiri yopangira laser yachitsulo chopangidwa ndi Fortune Laser, yomwe ndi yosavuta kugwiritsa ntchito, yokhazikika kuyendetsa ndipo ili ndi magwiridwe antchito abwino kwambiri.

➣ Ili ndi laibulale yodulira zinthu kuti ithandize ogwiritsa ntchito kupeza njira yabwino kwambiri yodulira zinthu.

➣ Amajambula kapena kusintha njira zojambula za 2D mwachindunji mkati mwa makina popanda kufunikira mapulogalamu ena, kuonjezera zokolola ndikupereka kufulumira kosagwirizana komanso kuwerengera kuchepa kwa mphamvu kuti mafuta azitha kusungunuka bwino.

➣ Makina opaka mafuta amagetsi amathandiza kuti zida zigwire ntchito bwino.

➣ Imapereka ntchito zokhazikika monga kudula kamodzi kokha, kuwerengera zokha, komanso kuchotsa fumbi m'deralo.

➣ Kuboola kwa mbale yopyapyala kosayambitsa, kuboola kwa mphezi ya mbale yokhuthala, kuboola kwa masitepe ambiri, kuchotsa mabowo a slag, kuletsa kugwedezeka, kuzungulira kotsekedwa kwa pressure, ukadaulo wogawa zigawo ndi ntchito zina zimathandizira kwambiri kukonza bwino komanso kukhazikika kwa kudula kwamphamvu kwambiri, ndikuwonjezera mpikisano pakati pa zida.

➣ Kupeza m'mphepete mwachangu komanso molondola kwambiri kuti zikwaniritse zofunikira za zinthu zojambulidwa komanso kulondola kwambiri.

➣ Dziwani kufalikira kwa chizindikiro chowonetsera, chizindikiro cha IO ndi chizindikiro cha USB kutali kwambiri.

➣ Chitetezo choletsa kugundana ndi torque, kupewa zopinga zoyenda ndi mpweya, luntha lotha kuuluka ndi ntchito zina.

Pulogalamu yopangira chisa imagwiritsa ntchito pulogalamu yapadera ya mzere wopangira laser wachitsulo cha mbiri yomwe yapangidwa mwamakonda, yomwe ndi yosavuta kugwiritsa ntchito, yokhala ndi ntchito yodziwikira yokha komanso kukonza mwachangu zikalata za batch.

➣ imathandizira kulowetsedwa mwachindunji kwa Tekla, Solidworks ndi mitundu ina ya 3D, ndipo imatha kujambula kapena kusintha mwachindunji njira yodulira chitsulo mu pulogalamu yopangira nesting, popanda mgwirizano ndi mapulogalamu ena, zomwe zimapangitsa kuti kukonza zolakwika ndi kusintha kukhale bwino.

➣ imasintha kapena kukonza mafayilo m'magulu, imathandizira kukonza ma node angapo olumikizidwa, ndipo imasintha njira zodulira zokha kuti zithandizire kudula m'mphepete mwa m'mphepete.

➣ Pulogalamuyi ili ndi kukhazikika kwakukulu, ndipo database yofananira ya njira ikhoza kukhazikitsidwa malinga ndi zipangizo zosiyanasiyana komanso makulidwe a mbale.

Magawo a Makina

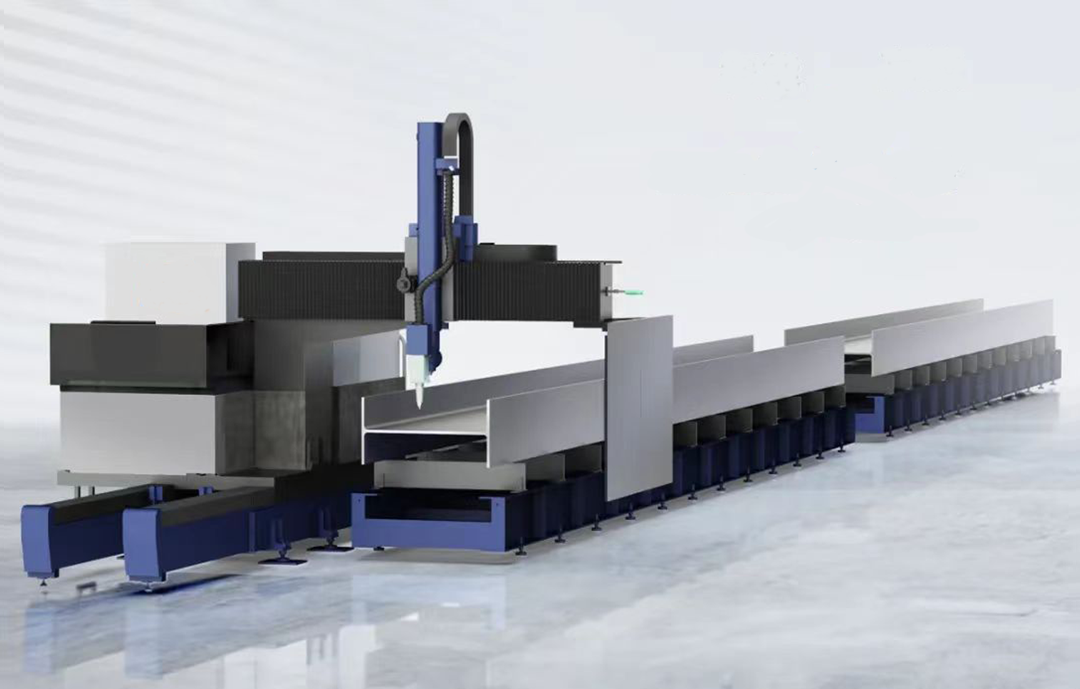

Kuwonetsera kwa Makina

Zitsanzo Zowonetsera

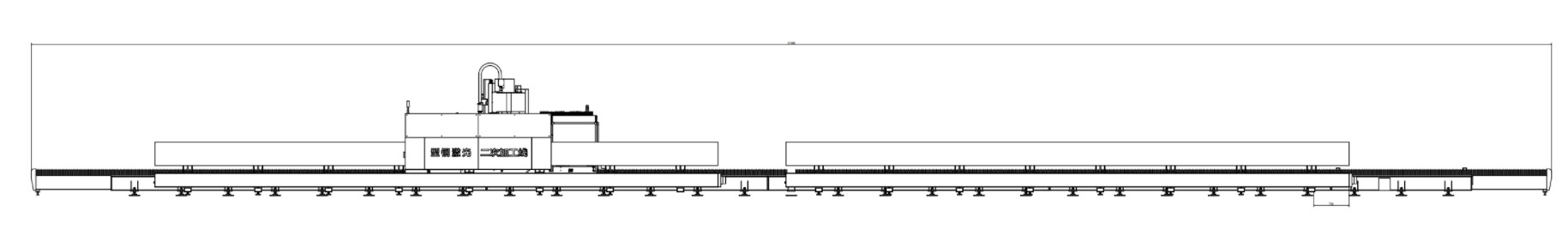

Kulinganiza bwino komanso kuyika kosavuta

Kudzera mu kuwotcherera dzenje lodula monga momwe zilili pamwambapa

Chiwonetsero chodulira cha bevel cha gawo la chitsulo cha madigiri 45