Makina Owotcherera a Fortune Laser Okhazikika a 1000W/1500W/2000W Ulusi wa Laser Wopitilira Nsanja

Makina Owotcherera a Fortune Laser Okhazikika a 1000W/1500W/2000W Ulusi wa Laser Wopitilira Nsanja

Mfundo Zoyambira za Makina a Laser

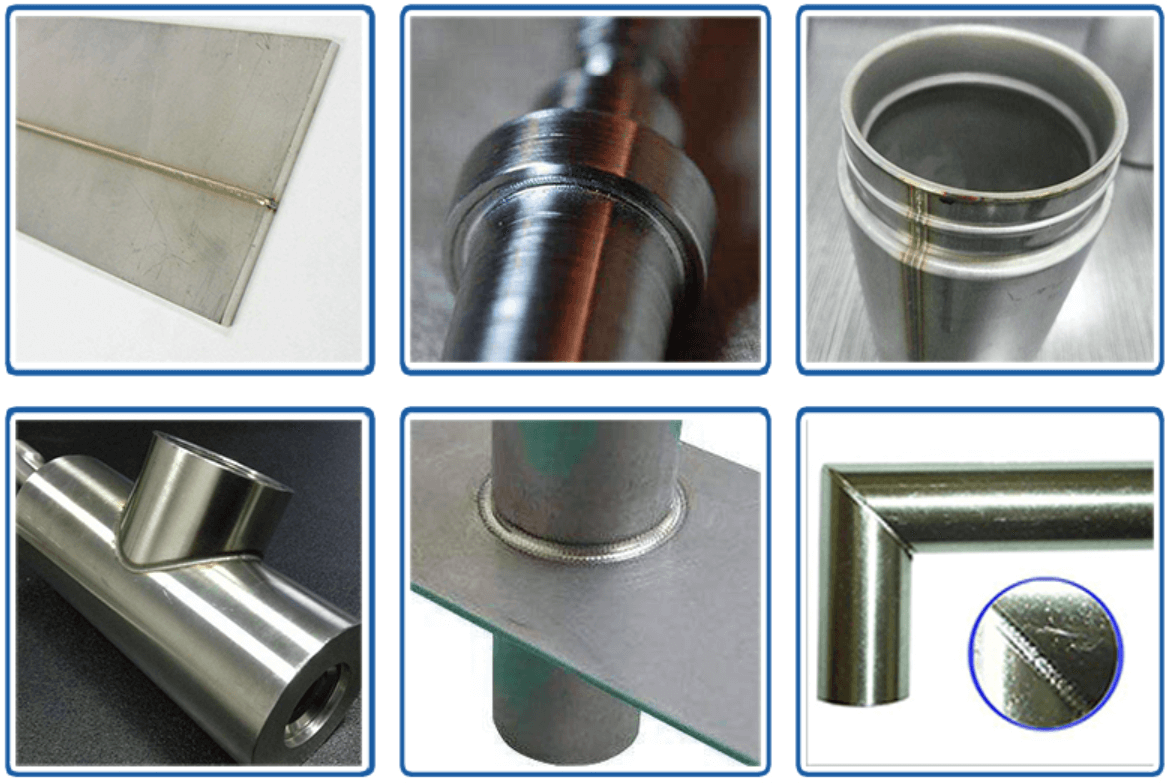

Makina olumikizira ulusi wa laser wopitilira ndi njira yatsopano yolumikizira. Nthawi zambiri amapangidwa ndi "wothandizira kulumikiza" ndi "benchi lolumikizira". Mzere wa laser umalumikizidwa ndi ulusi wowala. Pambuyo potumiza kutali, umakonzedwa kukhala wowunikira wofanana. Kulumikiza kosalekeza kumachitika pa chogwirira ntchito. Chifukwa cha kupitiliza kwa kuwala, mphamvu ya kulumikiza imakhala yolimba ndipo msoko wa kulumikiza umakhala wabwino komanso wokongola. Malinga ndi zosowa zosiyanasiyana za mafakitale osiyanasiyana, zida zolumikizira laser zimatha kufanana ndi mawonekedwe ndi benchi lolumikizira malinga ndi malo opangira ndikugwira ntchito yokha, zomwe zingakwaniritse zosowa za ogwiritsa ntchito m'mafakitale osiyanasiyana.

Makina ambiri odulira ulusi wa laser osalekeza amagwiritsa ntchito ma laser amphamvu kwambiri okhala ndi mphamvu yoposa ma watts 500. Nthawi zambiri, ma laser otere ayenera kugwiritsidwa ntchito pa mbale zopitirira 1mm. Makina ake odulira ndi odulira mozama kutengera zotsatira za dzenje laling'ono, okhala ndi chiŵerengero chachikulu cha kuzama ndi m'lifupi, chomwe chingafike pa 5:1, liwiro lodulira mwachangu, komanso kusintha pang'ono kwa kutentha.

Makina Owotcherera a Laser Opitilira 1000W 1500w 2000w Khalidwe

Makina Opangira ...

Zowonjezera

1. Gwero la laser

2. Chingwe cha Laser cha Ulusi

3. Mutu wowotcherera wa laser wa QBH

4. Choziziritsira cha 1.5P

5. PC ndi makina olumikizirana

6. 500*300*300 Linear Rail Servo Electric Translation Stage

7. Dongosolo lowongolera la 3600-axis anayi

8. Makina a kamera a CCD

9. Kabati ya Mainframe